Zero gas consumption low dew-point waste heat regenerative absorbent type dryer

An adsorption drying and low dew point technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high power consumption, low dew point, high dew point, etc., and achieve the effect of prolonging life and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be specifically described through embodiments below in conjunction with the accompanying drawings.

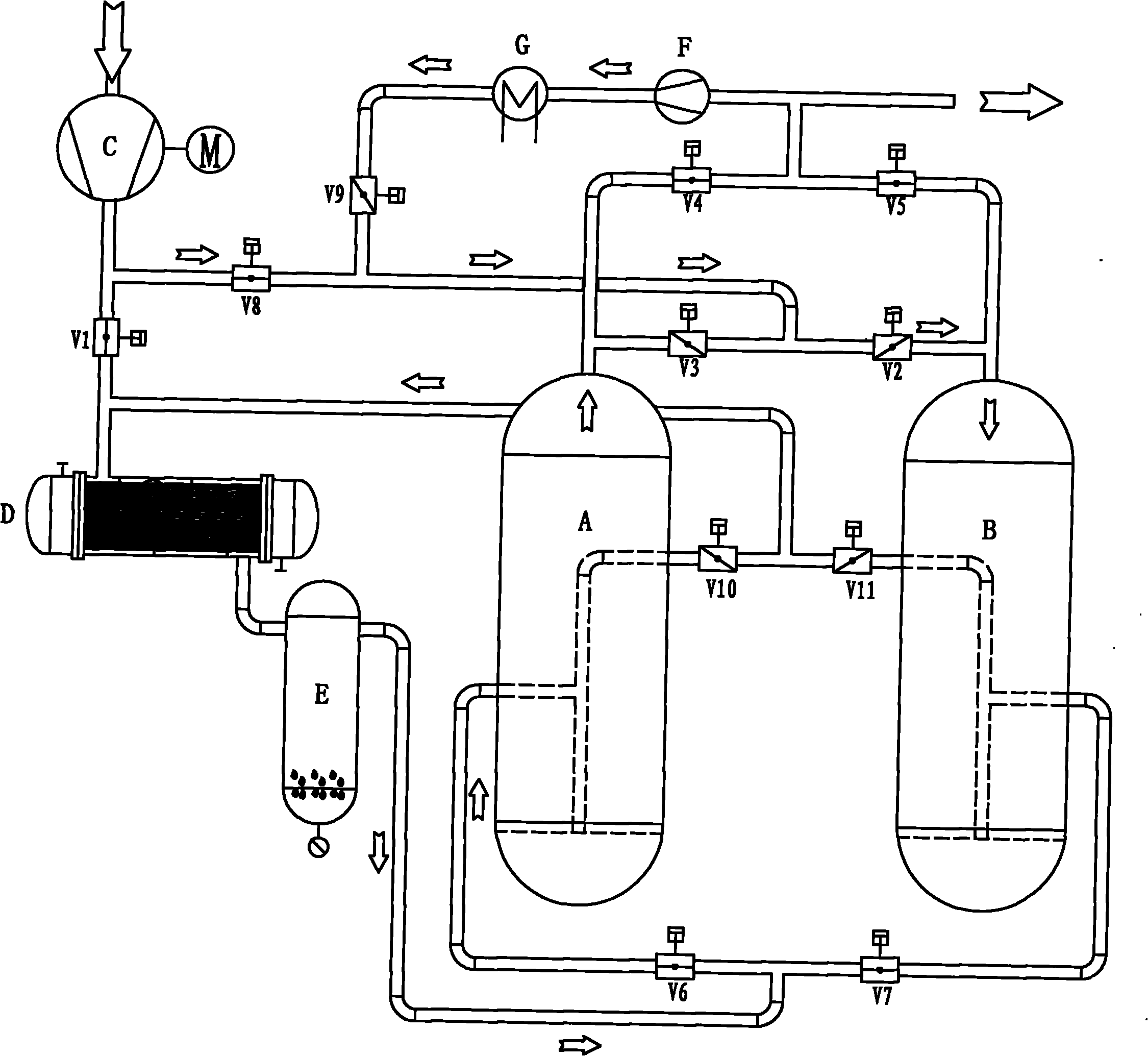

[0010] Such as figure 1 As shown, the present invention is connected to the rear stage of the air compressor (C), and the inlet of the drier is connected to the air compressor (C), including two left and right adsorption towers A, B, and the air compressor C is sequentially connected through the first valve V1 The water cooler D and the gas-liquid separator E are connected to the left adsorption tower A through the sixth valve V6, and connected to the right adsorption tower B through the seventh valve V7. The left adsorption tower A and the right adsorption tower B are respectively connected to the outlet of the dryer through the fourth valve V4 and the fifth valve V5.

[0011] Such as figure 1 As shown, the pipeline drawn between the air compressor C and the first valve V1 passes through the eighth valve V8, then connects between the fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com