Micro capsule type artificial feed suitable for orius sauteri

A technology of artificial feed and microcapsules, applied in animal feed, animal feed, application, etc., can solve the problems of rare scientific research literature, low yolk amount, low egg production and egg hatching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

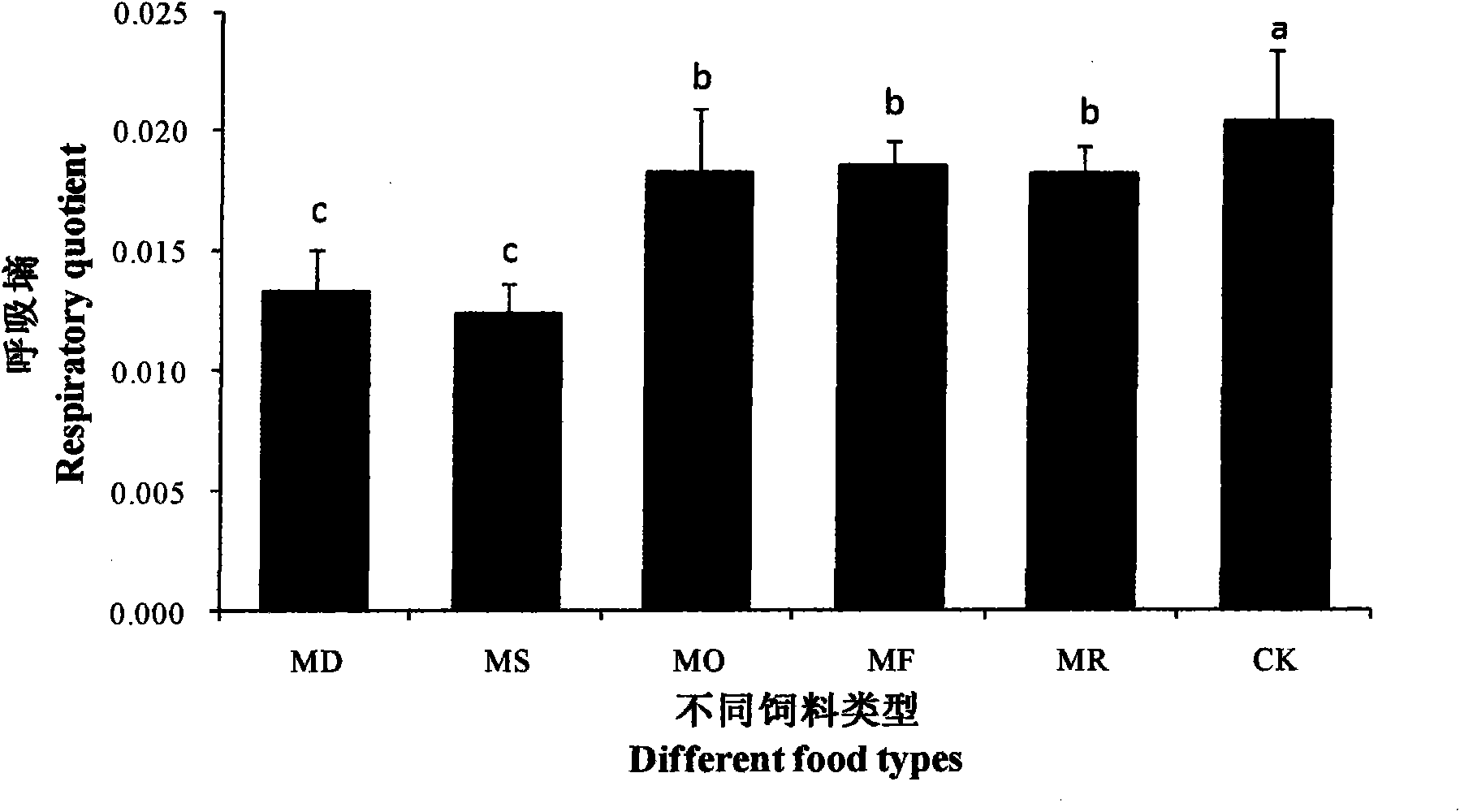

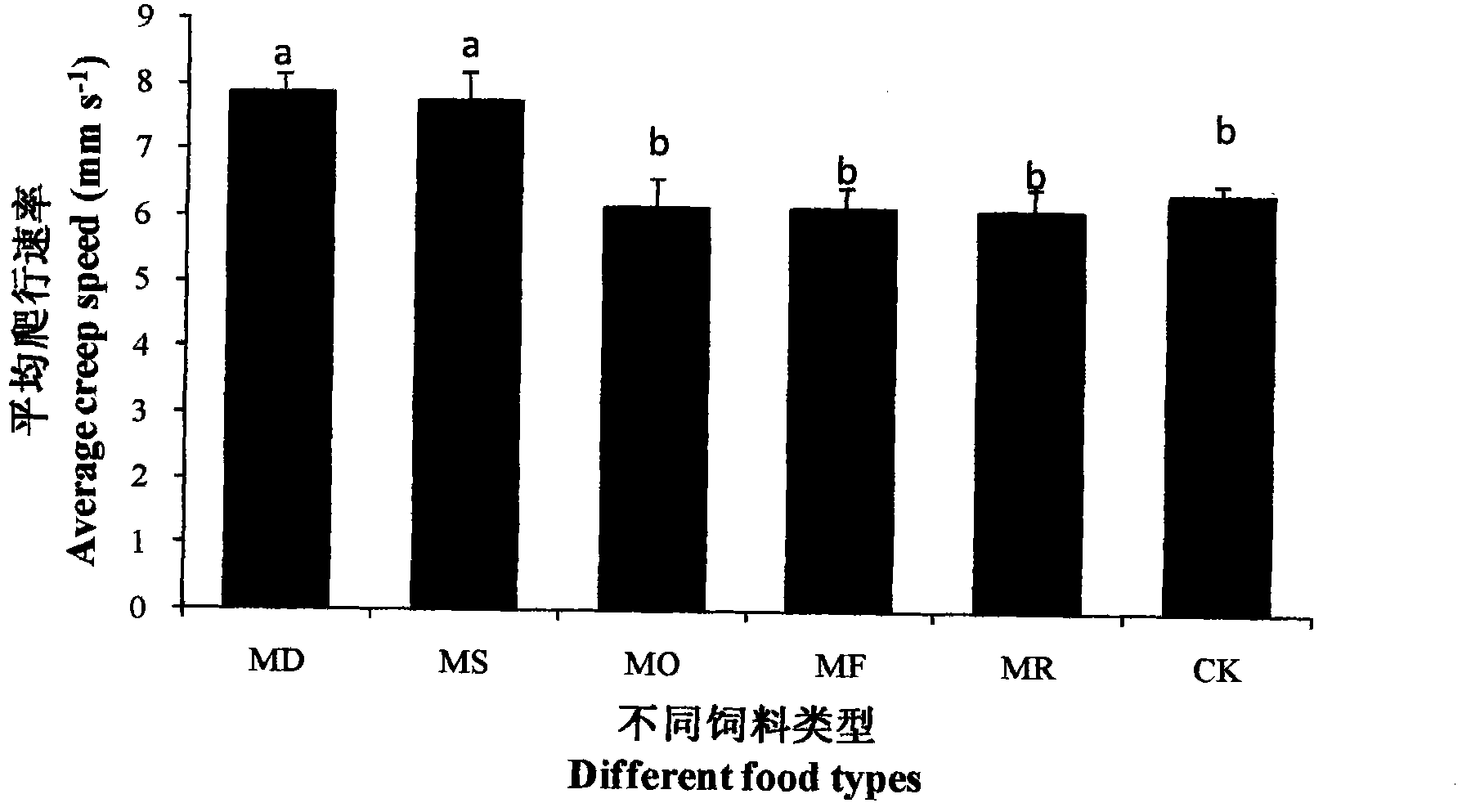

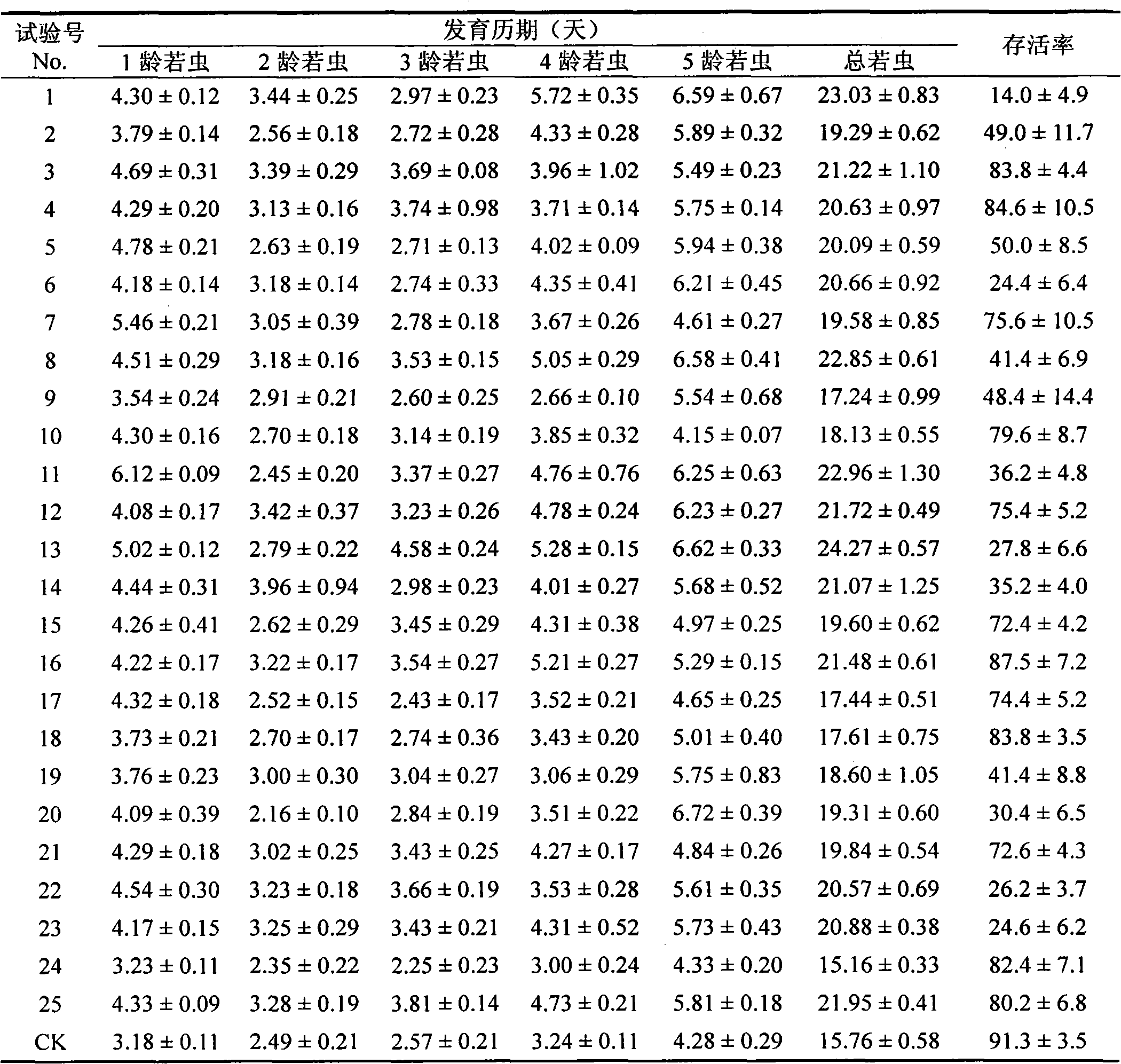

[0023] Combine below figure 1 , figure 2 As well as Table 1, Table 2, Table 3, and Table 4, the present invention is further explained. Production Example

[0024] (1) Preparation of artificial feed for East Asian small flower bug:

[0025] According to the manufacturing method of the present invention, the following raw material mass ratios are made into the standard range of the artificial feed for the microcapsule bug:

[0026] Egg yolk: Tussah pupa homogenate: sucrose: honey: choline: rape pollen equal to 0-50: 30-50: 8-10: 5-15:0-20:0-10;

[0027] The production method is:

[0028] Take the raw materials of each component according to the above-mentioned mass ratio, put them into distilled water in turn, stir to dissolve; and store at low temperature after constant volume.

[0029] Taking 20 grams of sucrose as an example, the specific preparation steps are as follows: take the raw materials of each component according to the above-mentioned mass ratio, put them into 300 ml of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com