Device for injecting compressed air into a blow mold

A technology of compressed air and cylinders, which is applied in applications, household components, household appliances, etc., and can solve problems such as expensive, poor stop vibration, high production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

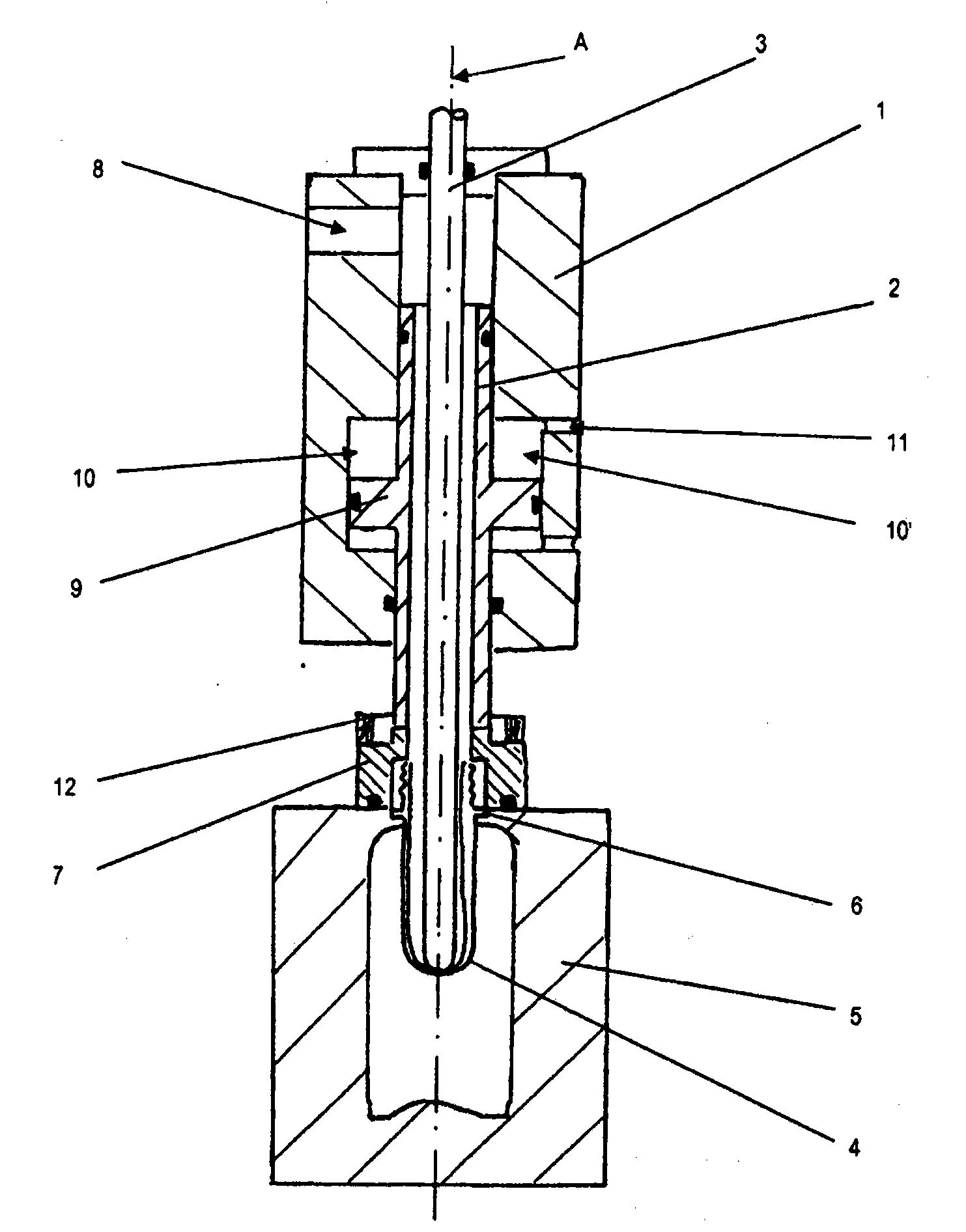

[0031] exist figure 1shows a fully schematic longitudinal section of a conventional blow molding cylinder of a stretch blow molding machine for producing eg PET bottles. A stretch rod 3 is arranged coaxially with respect to the hollow shaft 2 in the housing 1 of the blow molding cylinder. The stretch rod 3 protrudes upwards from the housing 1 leading to a separate drive for the stretch rod 3 (not shown). The lower end of the stretch rod 3 leads in a lowered state into the parison 4 of the PET bottle to be blown, which is itself secured in the blow mold 5 by its neck ring 6 .

[0032] At its lower end, the hollow shaft 2 has a sealing bell 7 which, in the example shown, is in tight contact with the upper side of the blow mold 5 in the operating position of the hollow shaft 2 . Now via the pressure tube 8 compressed air can be blown down through the hollow shaft 2 into the parison 4 and the parison is blown into its final shape according to the shape of the blow mold 5 . Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com