Full automatic water coal slurry burner and control method by adopting same

A technology of coal water slurry and burner, which is applied in the direction of burner, control combustion, lighting and heating equipment, etc., can solve the problems of high equipment maintenance frequency, increased use cost, complex structure, etc., to save manpower, improve work efficiency, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

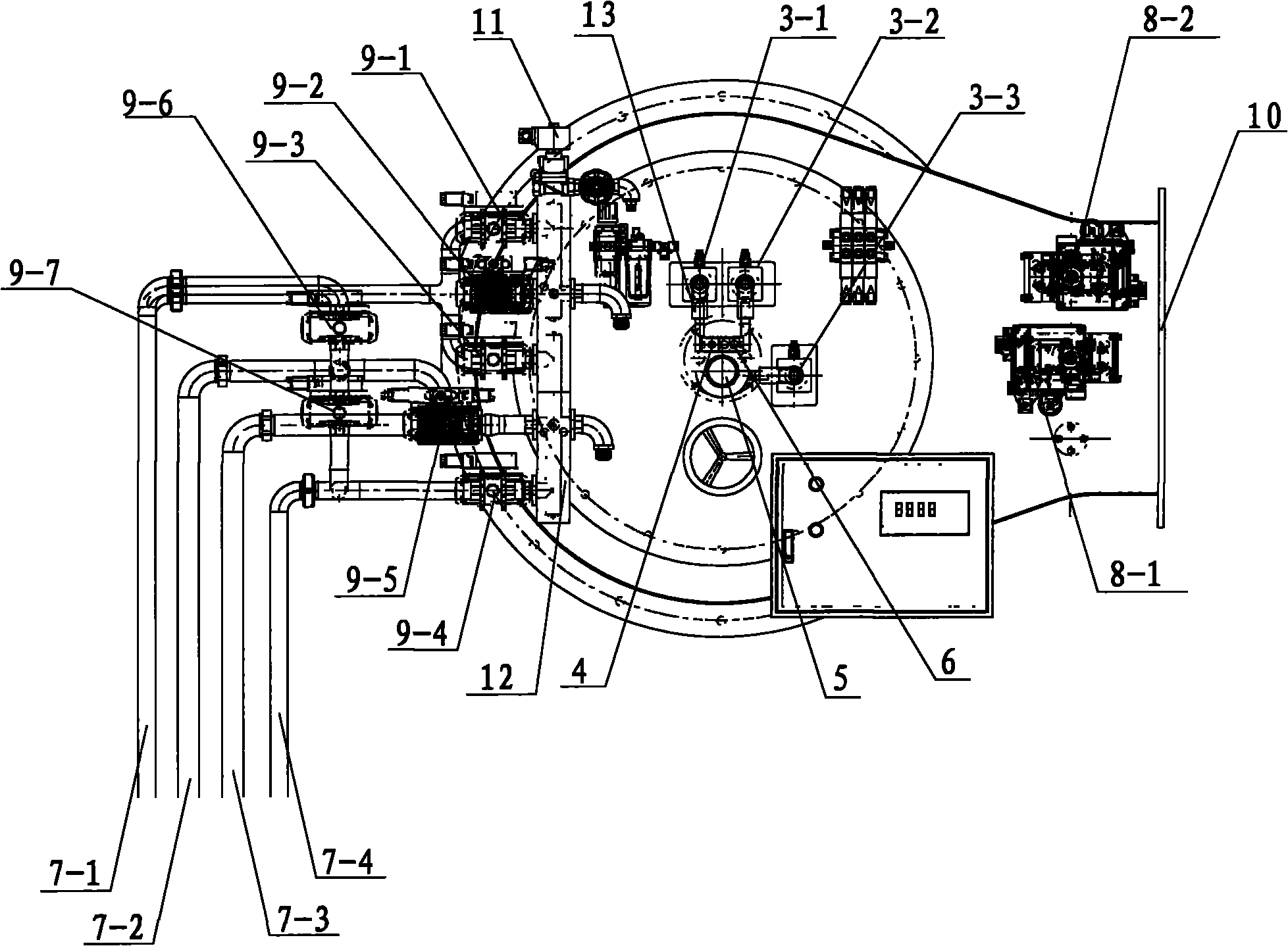

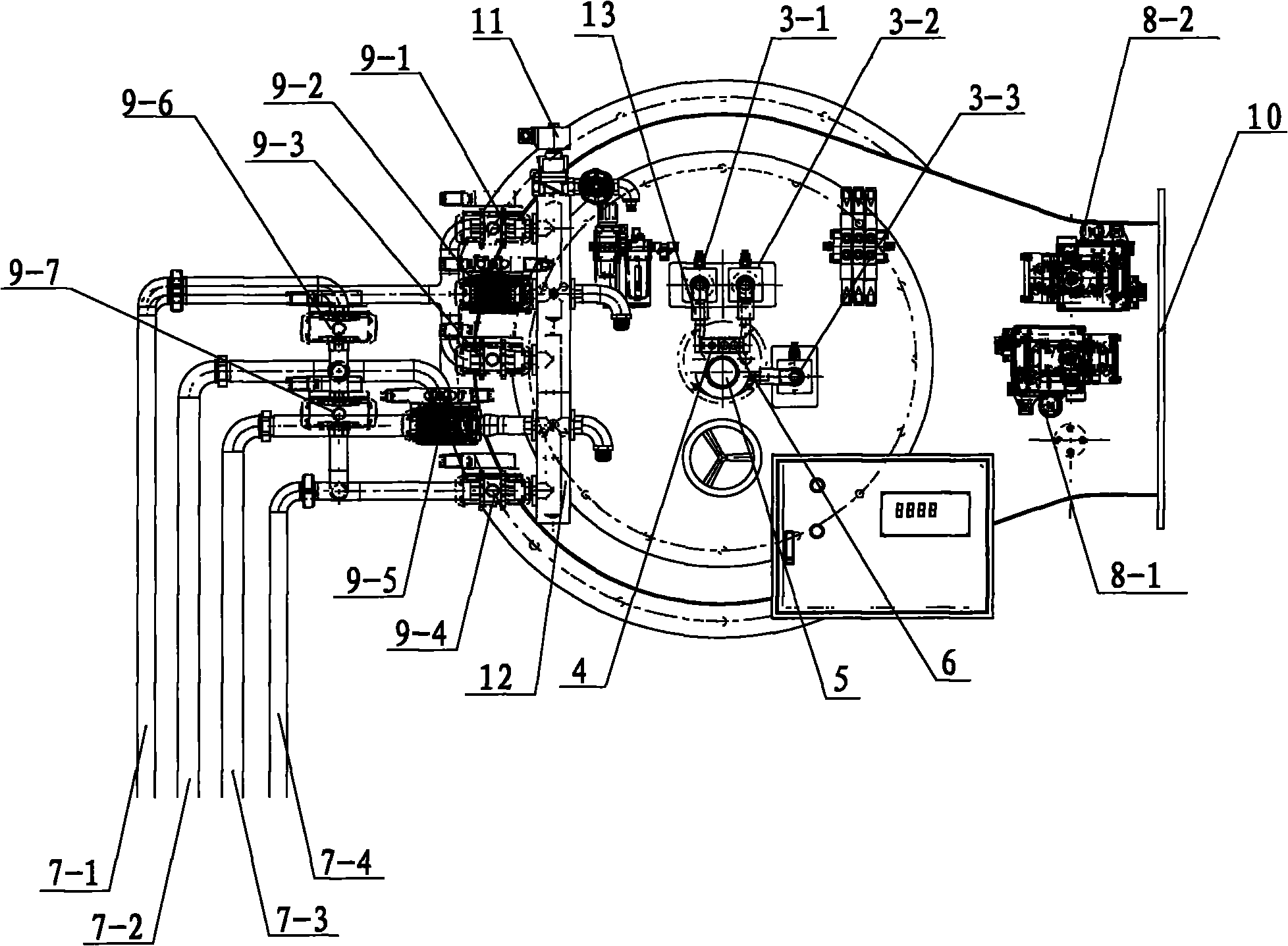

[0024] This equipment includes a casing 1, the inside of the casing is hollow to form a casing cavity 2, and the outer panel of the casing 1 is provided with cylinders 3-1, 3-2, 3-3, spray gun execution parts, and the spray gun execution parts include oil guns 4. The slurry gun 5, the high-pressure ignition gun 6, and the cylinder and the execution part of the spray gun are rigidly connected by a clamp 13. There is a fixed module 12 on the casing, one end of the fixed module 12 is connected to the pneumatic ball valve, the other end is connected to the spray gun actuator through a stainless steel hose, and the other end of the pneumatic ball valve is connected to the supply pipeline assembly; the fixed module 12 is fixed with a solenoid valve 11. The solenoid valve 11 is electrically connected with the air cylinder and controls the action of the air cylinder.

[0025] There is a pipeline assembly on the end surface of the casing. The pipeline assembly includes an air supply pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com