Bidirectional flywheel assembly

A dual-mass flywheel, flywheel technology, applied in the direction of flywheel, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of high overall price, unsatisfactory connection between primary mass and secondary mass, etc., and achieve a small moment of inertia. , excellent driving comfort, easy shifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

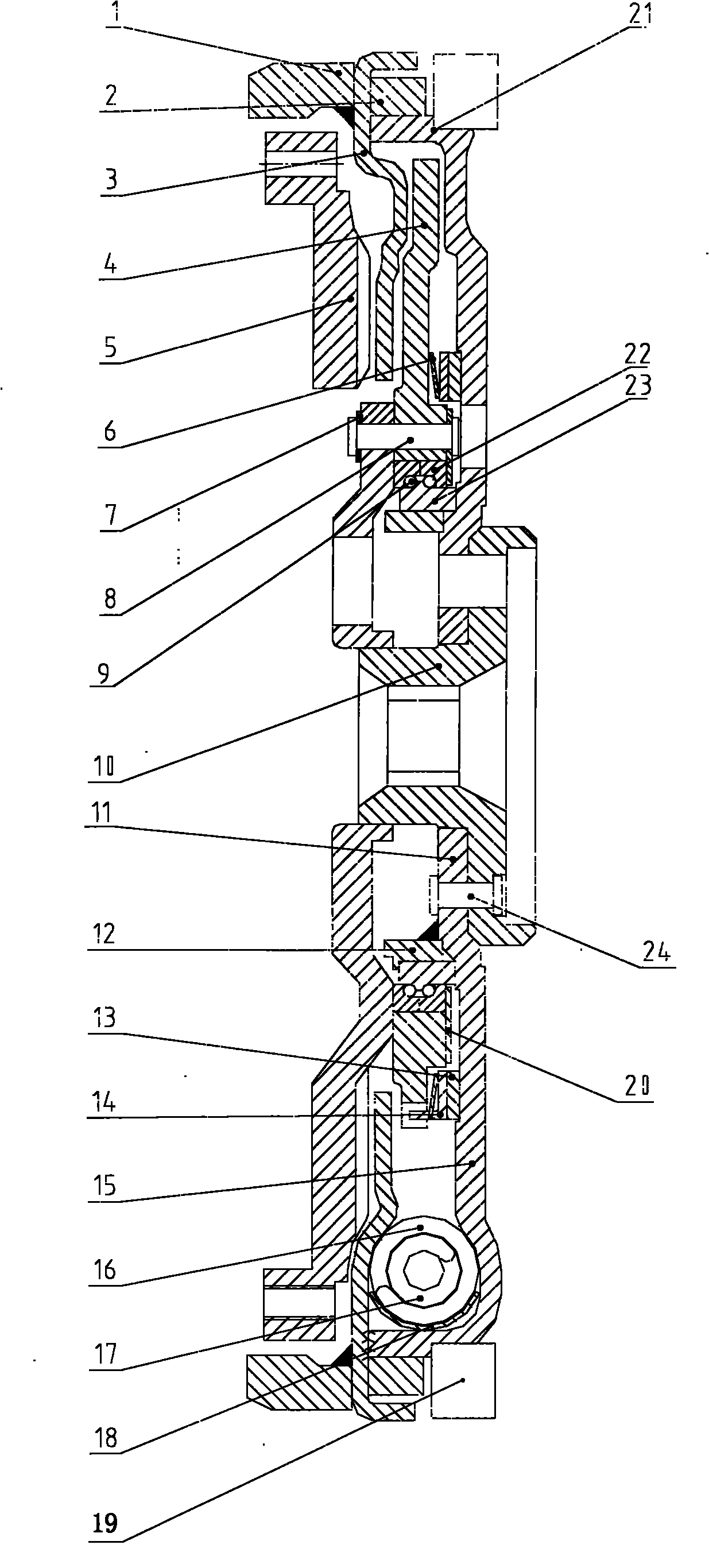

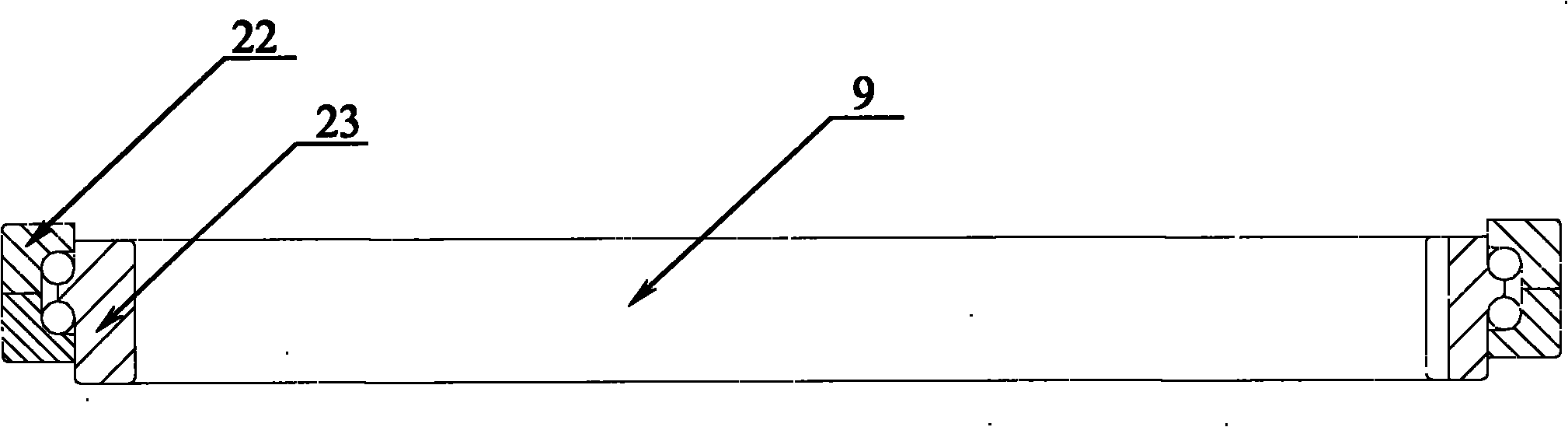

[0015] Such as figure 1 and 2 As shown, a dual-mass flywheel assembly includes a spring, a flywheel driving disc 11, a positioning disc 10, a flywheel damping disc 3, a flywheel hub 4, a flywheel disc 5, a ring gear 19, a decorative ring 1 and a two-way limiter Bridge bearing 9. The flywheel driving disc 11 is riveted with the positioning disc 10, welded with the flywheel damping disc 3, and the flywheel damping disc 3 is welded with the decorative ring 1; the outer circle of the flywheel driving disc 11 is provided with a stop 21, and the ring gear 19 passes through the stop. The port 21 is closely connected with the flywheel driving disc 11; the outer circle of the flywheel driving disc 11 is covered with a fastening ring 2. Its flywheel disc 5, flywheel disc hub 4 and two-way limit bridge bearing compression ring 20 are riveted together by assembly rivets 8, and an assembly rivet pad 7 is set between the flywheel disc 5 and the assembly rivets 8. A friction washer 13, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com