Pneumatic braking jig dyeing machine of gear swing-arm single motor

A pneumatic brake, single-motor technology, applied in textile processing machine accessories, liquid/gas/vapor open-width fabric processing, textiles and papermaking, etc. emission reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

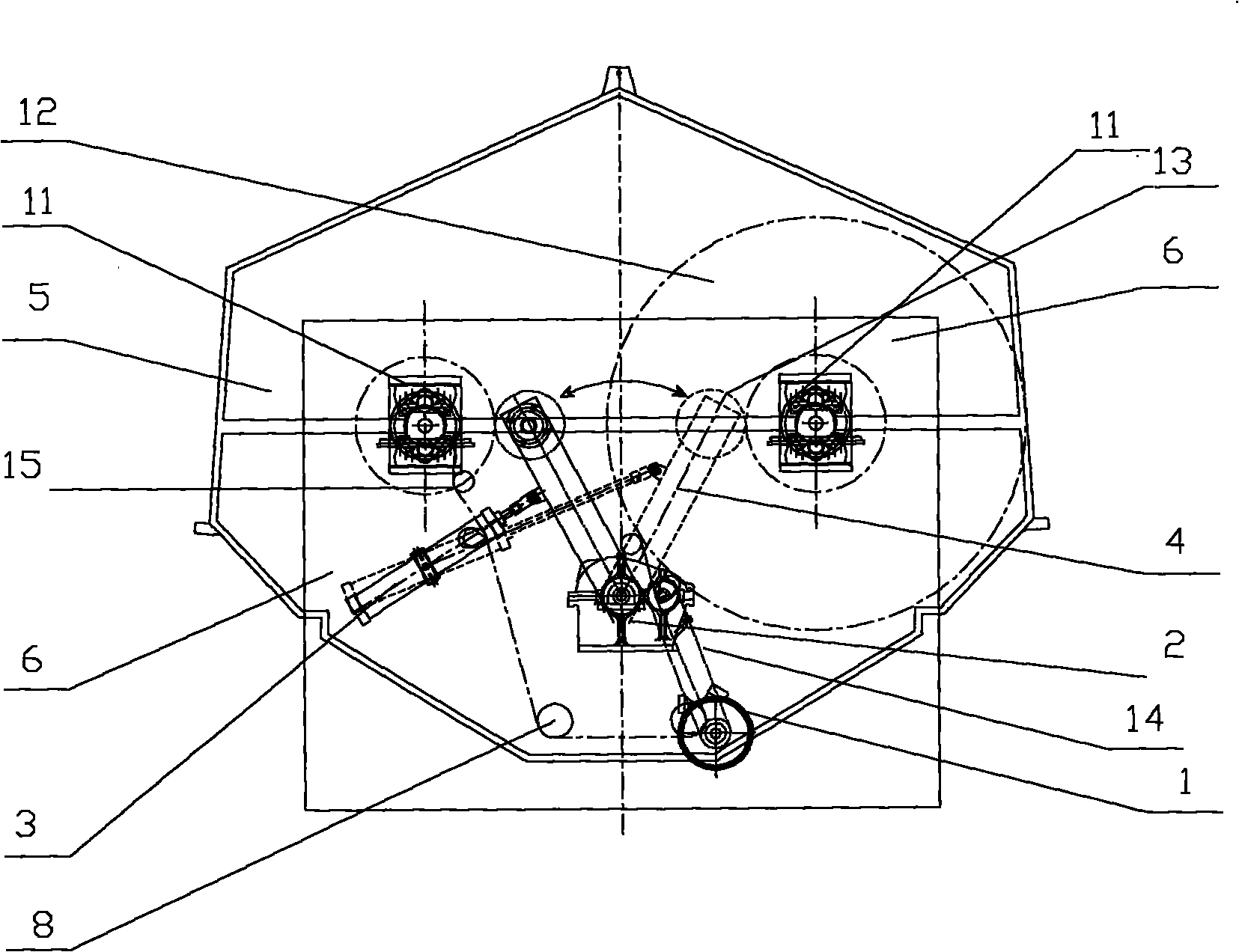

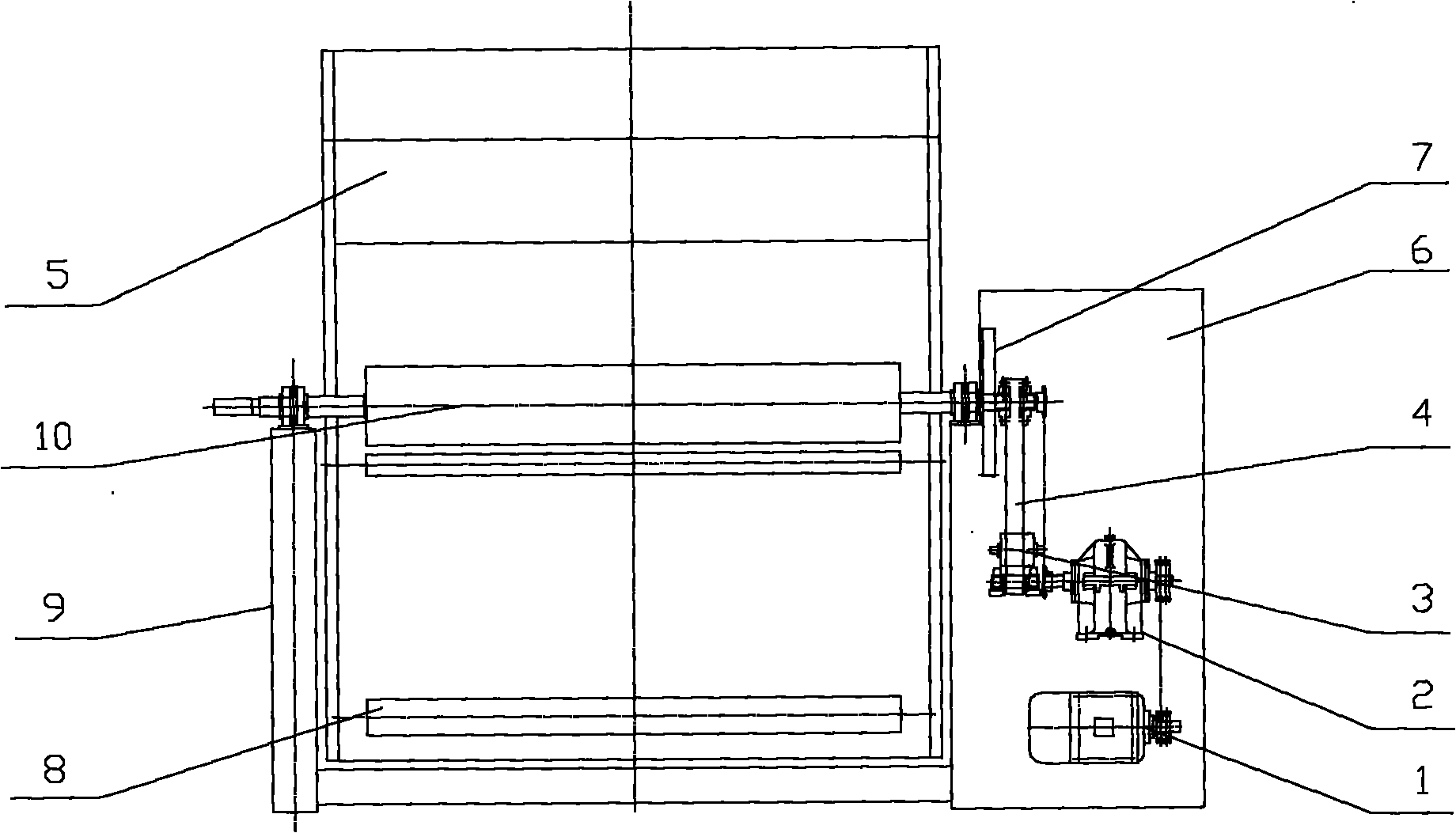

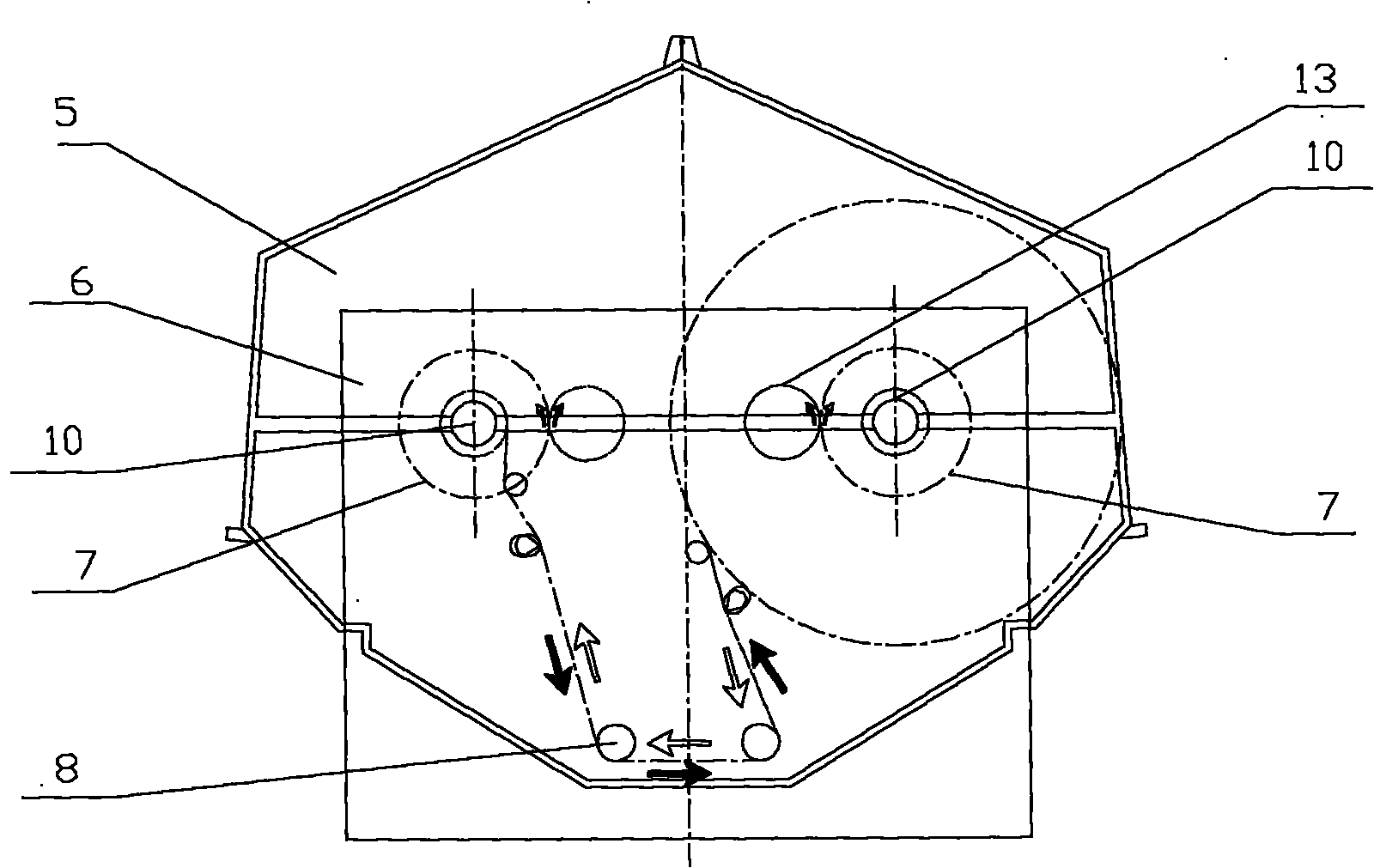

[0008] The invention as figure 1 As shown, by the dyeing vat 5, the head box 6, the pneumatic brake device 11, the fabric guide roller 8, the tension frame 15, the main drive swing gear 13, the transmission arm 4, the cylinder 3, the reducer 2, the motor 1, the transmission mechanism 14, Two passive large gears 7, frame 9, figure 2 Shown, the left cloth roll 10, the right cloth roll 10, image 3 composition as shown. The motor 1 is decelerated by the transmission mechanism 14 connected to the reducer 2; as figure 1 , 2 As shown, the lower end of the transmission support arm 4 is assembled on the output shaft of the reducer, such as figure 2 , 3 As shown, the main drive swing gear 13 is installed on the upper end of the transmission support arm, and the passive large gear 7 is respectively installed on the one end shaft 10 of the left and right cloth rolls. The cylinder 3 is connected with the transmission support arm 4, and the cylinder 3 has the function of traction an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com