Lifting spring group structure of power-off suspension arm

A technology of spring sets and booms, which is applied in cranes, portable lifting devices, hoisting devices, etc., can solve the problems of inseparability, large investment, inconvenient disassembly and removal, etc., and achieve the improvement of limitations, simple structure of the device, and easy disassembly moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

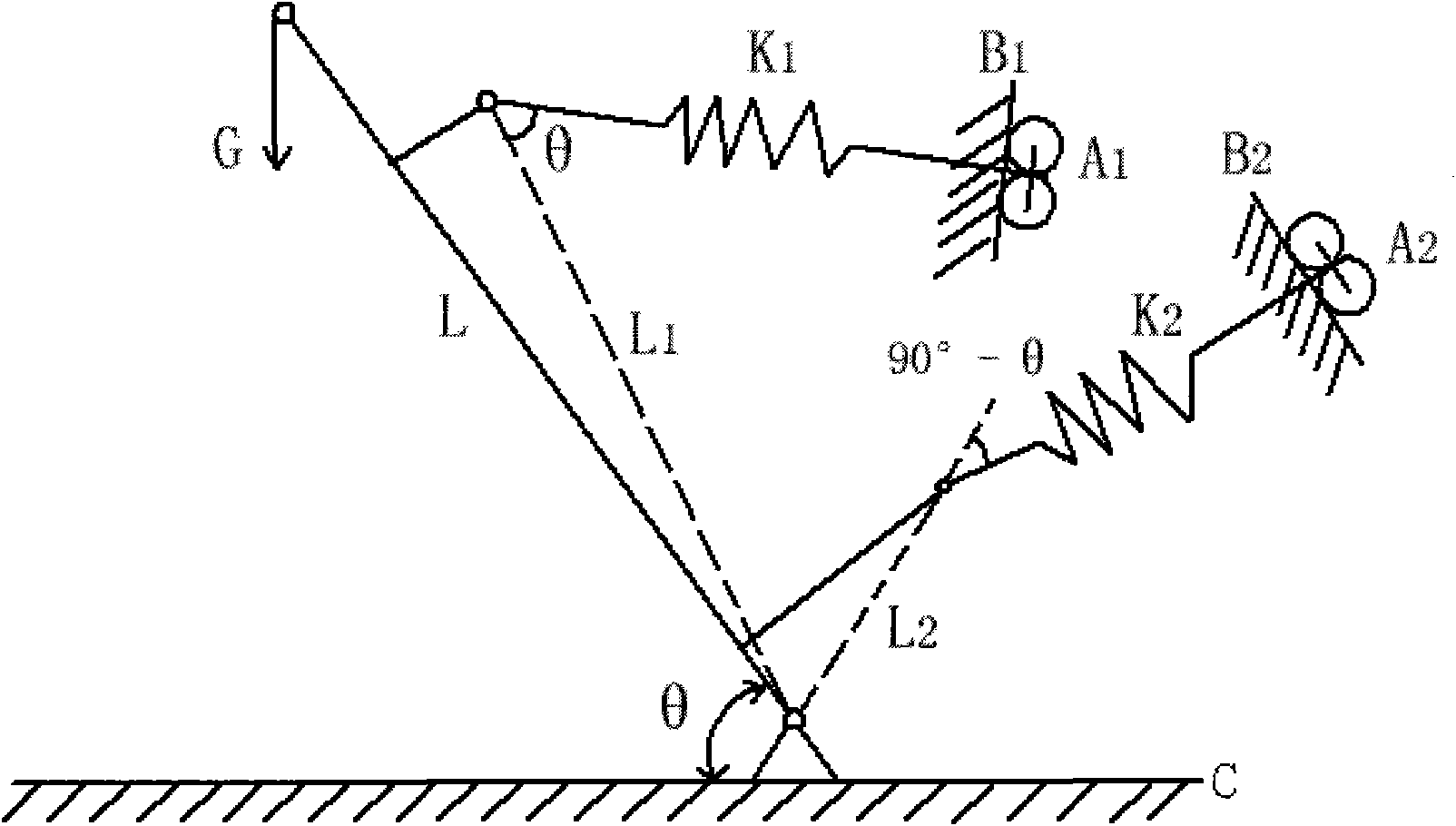

[0019] Such as figure 1 , is the general structure of the single-arm lifting residual angle spring group device, the residual angle spring group K 1 and K 2 One end of each through the roller device A 1 and A 2 Attached to the fillet spring set fixture B 1 and B 2 and can slide, and the other end is connected to the boom L. The top end of the boom L bears the weight G, and the bottom end is connected to the boom fixing structure C. Complementary spring set K 1 and K 2 The action arms are L 1 and L 2 .

[0020] where K 1 with L 1 The included angle θ is always equal to the included angle between the boom L and the horizontal plane, and K 2 with L 2 The angle between them is always 90°-θ; two complementary angle springs K 1 and K 2 The relationship between the strength of and its action arm satisfies K 1 / K 2 =(L 2 / L 1 ) 2 . When the structure is installed, as long as the above conditions are met, a certain fixed weight G can be balanced at any lifting ang...

Embodiment 2

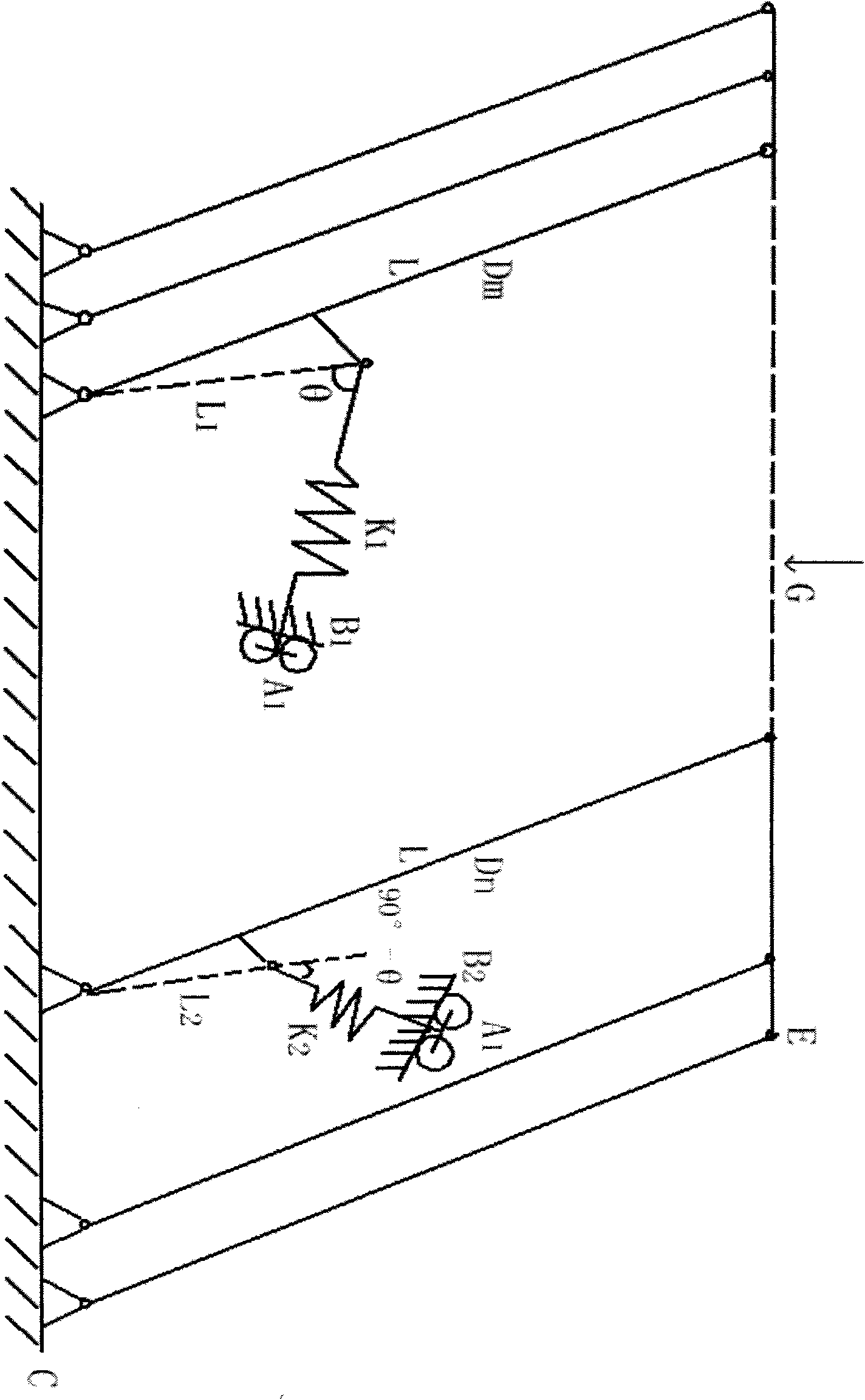

[0022] Such as figure 2 , is the general structure of the supplementary angle spring group device for lifting the parallel link boom, and the supplementary angle spring group K 1 and K 2 One end of each through the roller device A 1 and A 2 Connecting fillet spring set fixture B 1 and B 2 And can slide, the other end is connected with the boom Dm and Dn respectively, the length of the boom of the parallel link is L, and the heavy object bearing layer E at the top can bear the heavy object G, such as a car or a large cargo with a large volume, so that this The application scope of the invention is wider, the bottom end of the parallel link boom is connected with the boom fixing device C, and the supplementary angle spring group K 1 and K 2 The action arms are L 1 and L 2 .

[0023] where K 1 with L 1 The included angle θ is always equal to the included angle between the boom and the horizontal plane, and K 2 with L 2 The angle between them is always 90°-θ; two com...

Embodiment 3

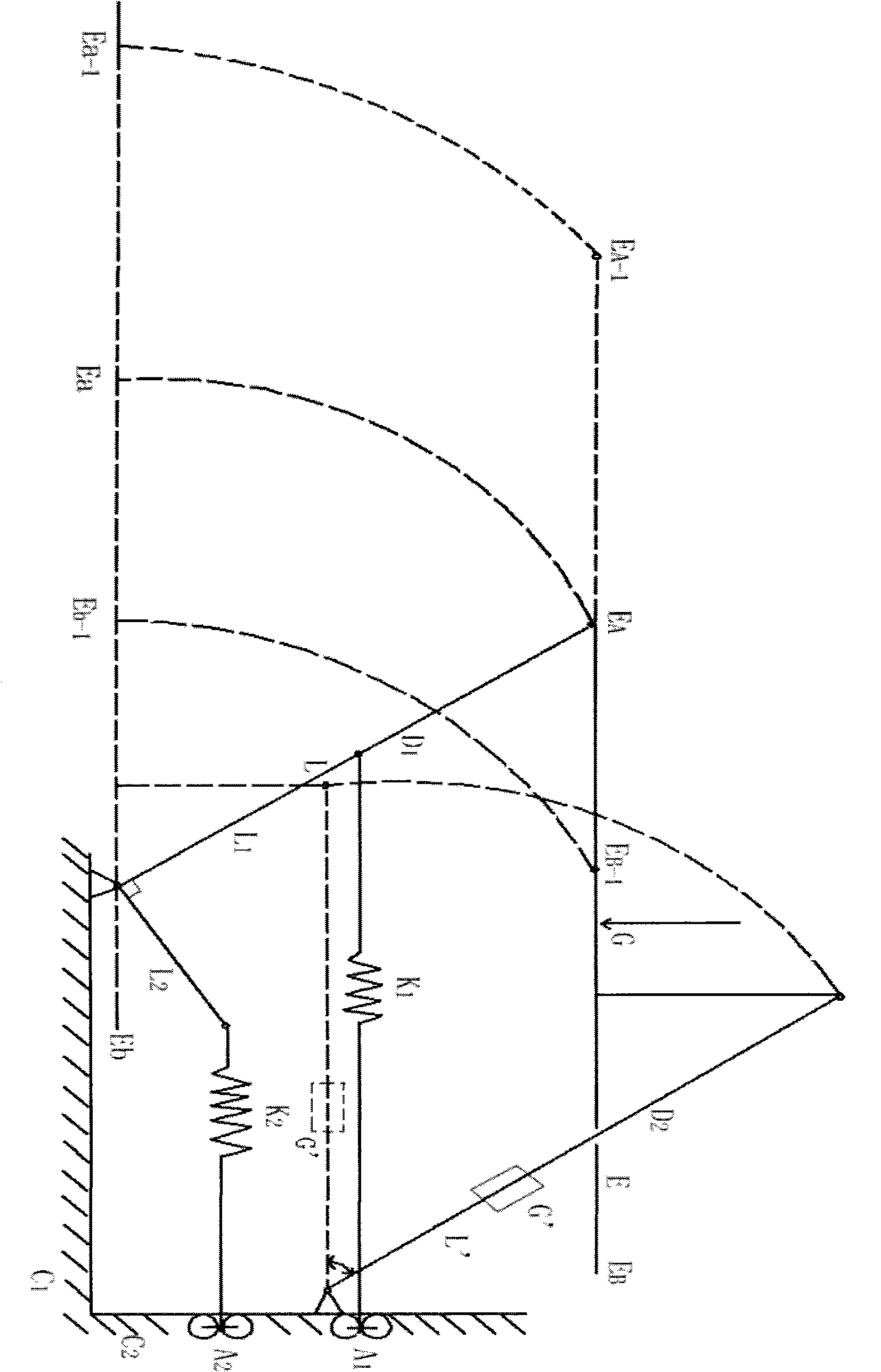

[0025] Such as image 3 , is a parallel connecting rod double-arm lifting residual angle spring set device and double-layer storage structure, residual angle spring set K 1 and K 2 average level, respectively through the roller device A 1 and A 2 Vertical Fixture C for Attaching Filled Corner Spring Sets 2 up, K 1 and K 2 The other end is connected to the same boom D 1 , parallel link boom D 1 and D 2 The bottom ends of the booms are respectively connected to the boom fixing structure C 1 and C 2 ,D 1 and D 2 The length of each is L, and the top is directly connected to the load-bearing layer E, and at D 2 Install counterweight G' on it. when D 1 and D 2 When in the horizontal position, the counterweight G' can be at D 2 Sliding up, supplementary angle spring set K 1 and K 2 The action arms are L 1 and L 2 , the action arm of the counterweight G' is L'.

[0026] where K 1 with L 1 The included angle θ is always equal to the boom D 1 angle with the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com