Method for assembling automobile gauge point

An assembly method and a technology of automobile instruments, which are applied to household components, household appliances, and other household appliances, etc., can solve the problems of failing to pass the customer's appearance and size report, and B-side warping, so as to improve the pass rate and work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] The present invention is realized through the following steps:

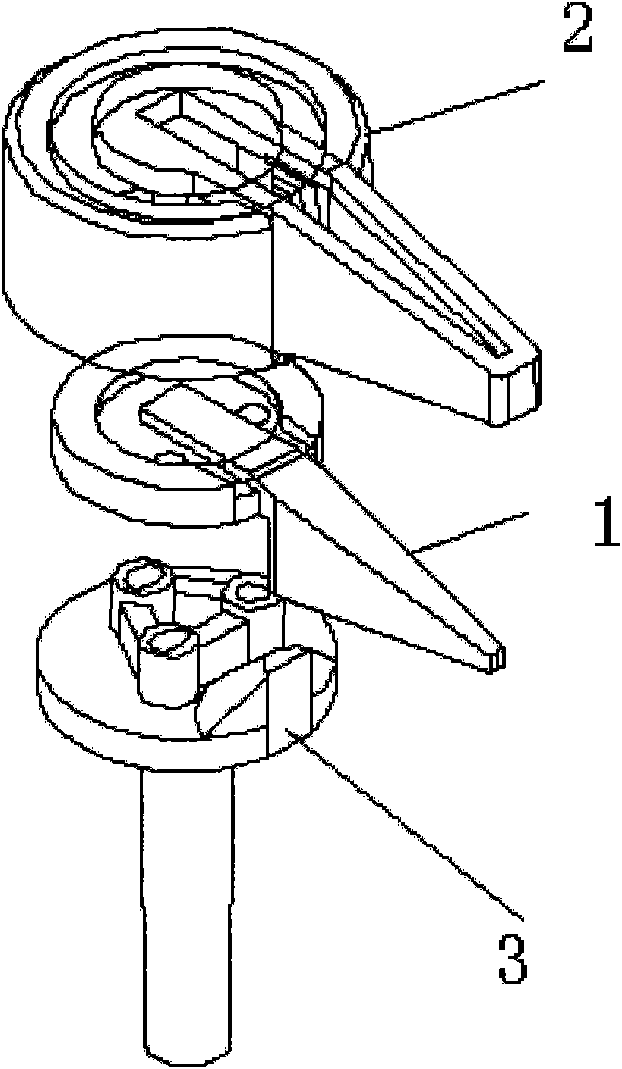

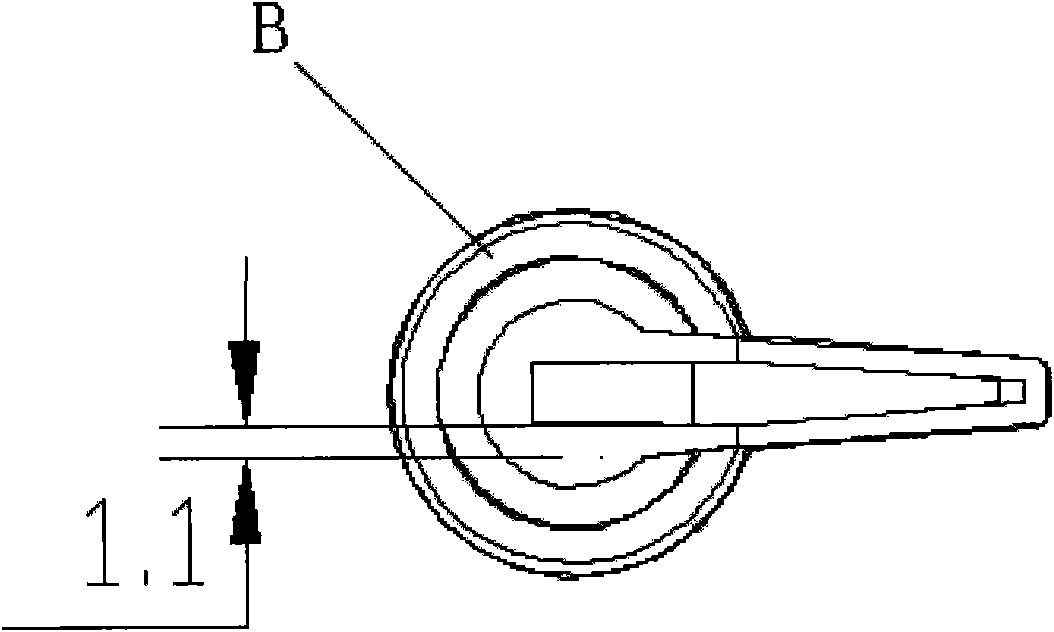

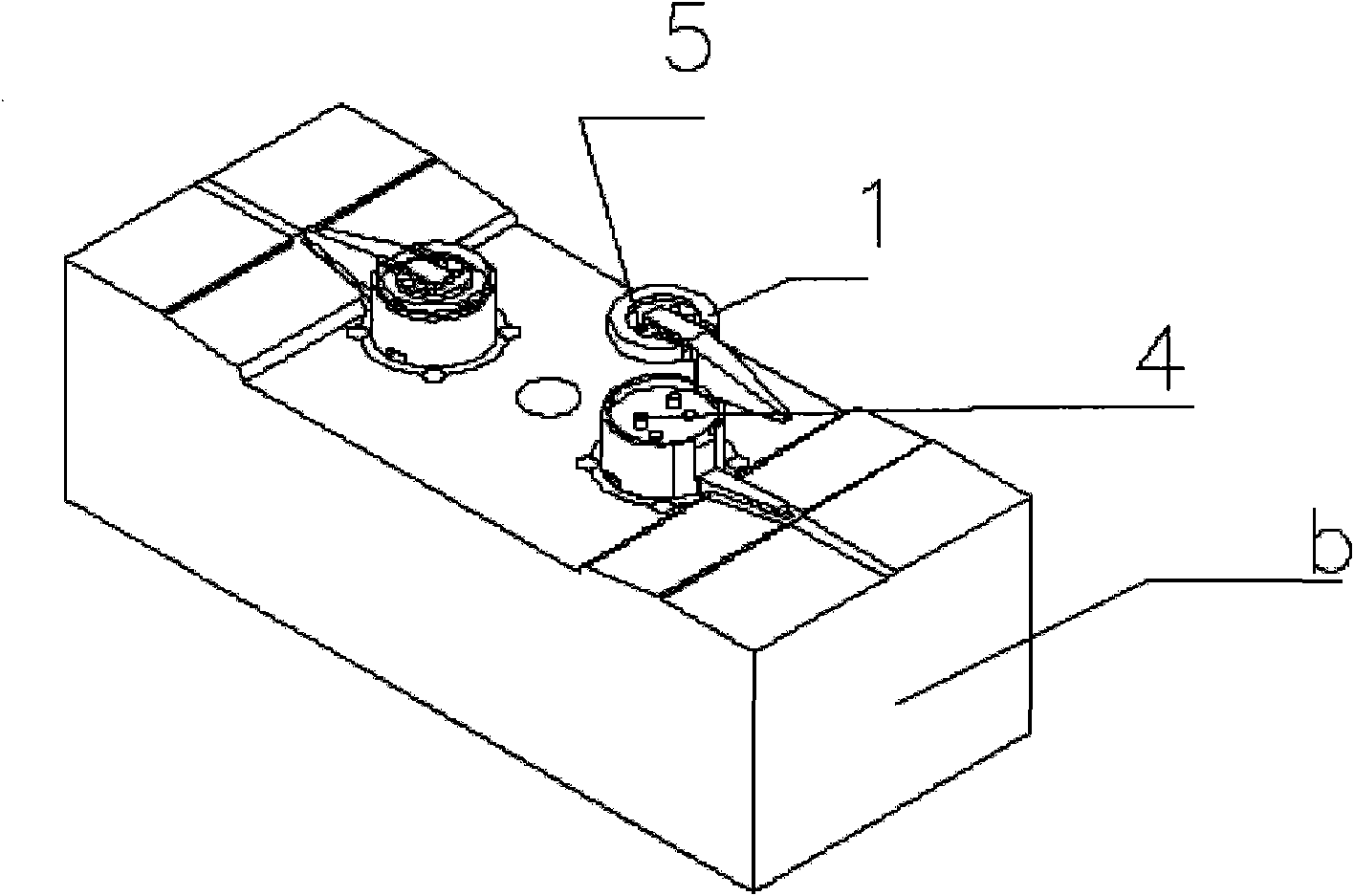

[0021] Such as image 3 Shown: Put the pointer 1 of the molded part that has been injected into the finished needle socket lower mold core b plate;

[0022] The positioning of the pointer in the mold core b is carried out by two positioning holes 5 on the pointer and two positioning nails 4 on the lower mold core b plate;

[0023] Such as Figure 4 , Figure 5 Shown: When the upper mold core a plate of the needle sleeve and the lower mold core b plate are molded together, the pointer is completely fused by the plastic;

[0024] The combination of pointer and needle cover 2 is completed through this injection molding;

[0025] When the upper mold core plate a and the lower mold core plate b are parted,

[0026] Such as Figure 6 As shown: the formed assembly 7 is left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com