Pre-calculation method for controlled cooling of thick plate after rolling

A technology of controlled cooling and pre-calculation, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems that do not involve the pre-calculation method of the thick plate cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

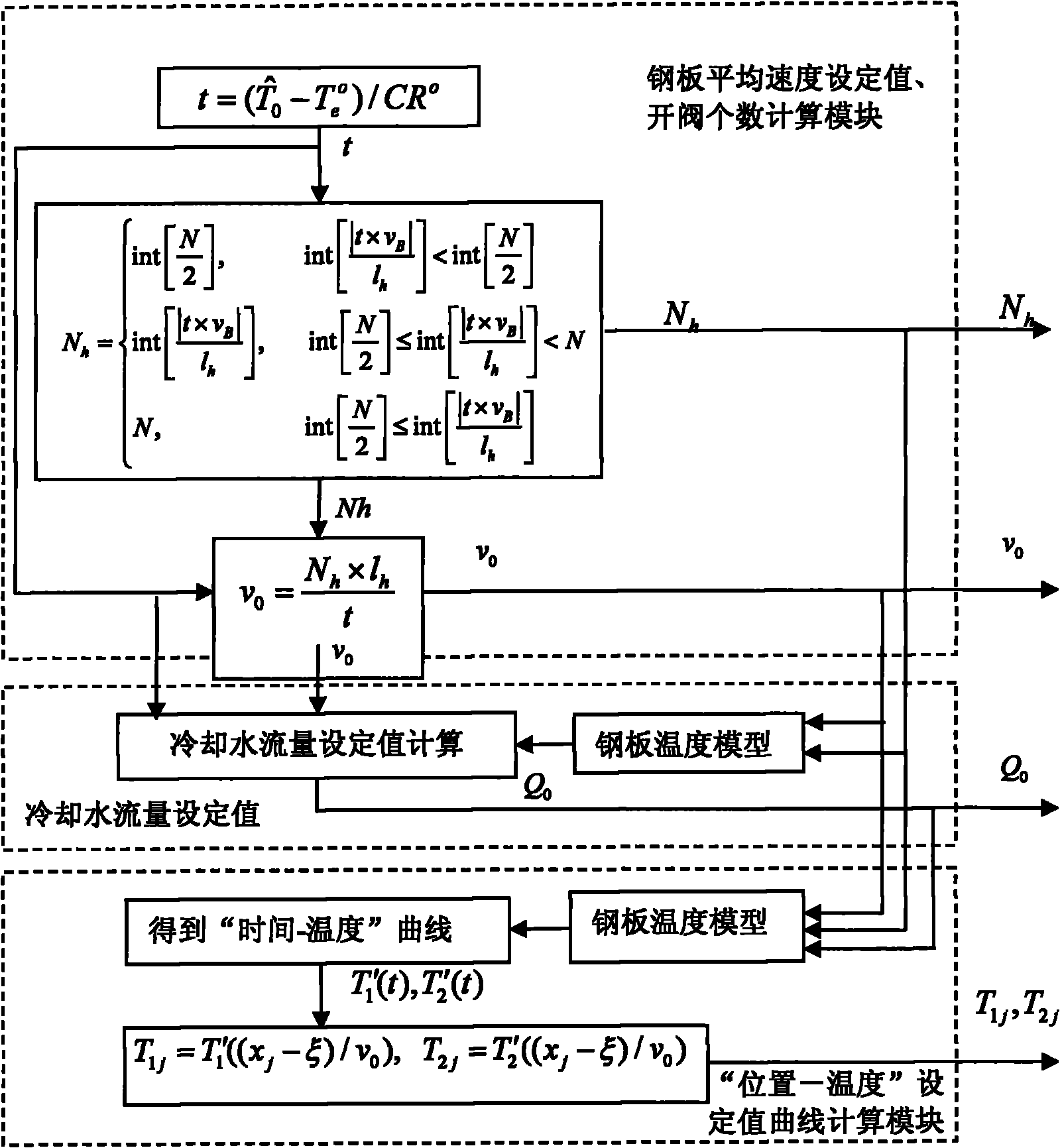

Method used

Image

Examples

Embodiment Construction

[0074] Below with the help of figure 1 To Fig. 9 further illustrate the present invention:

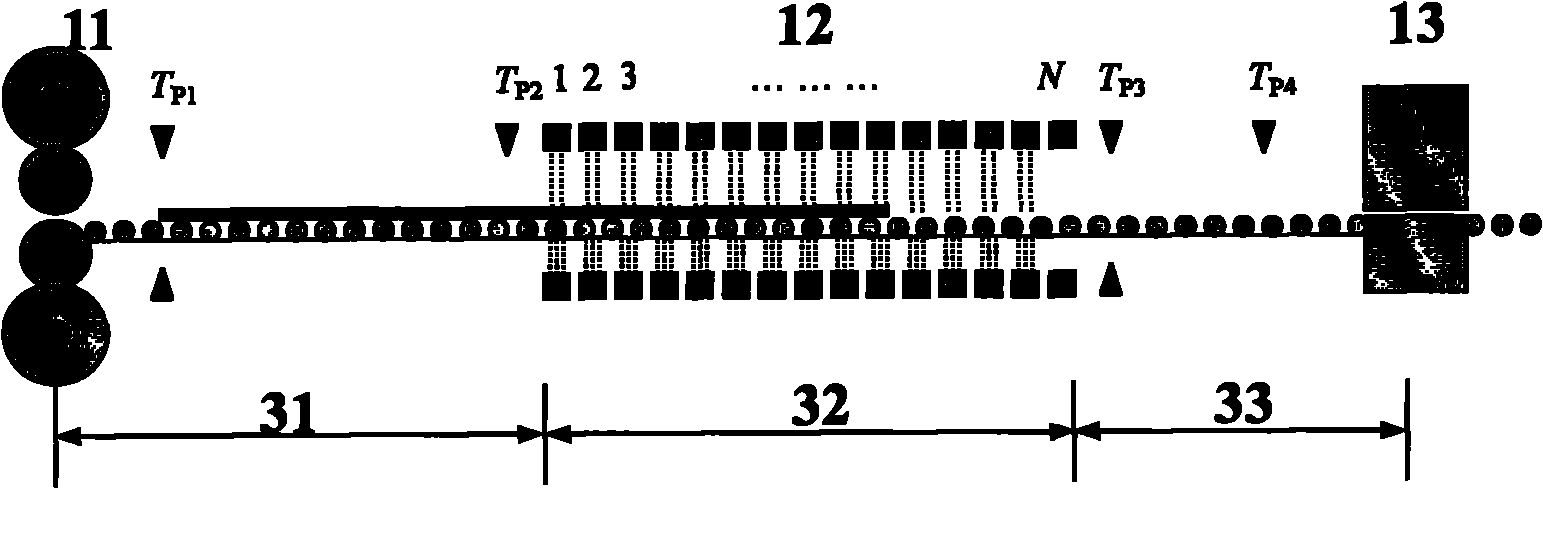

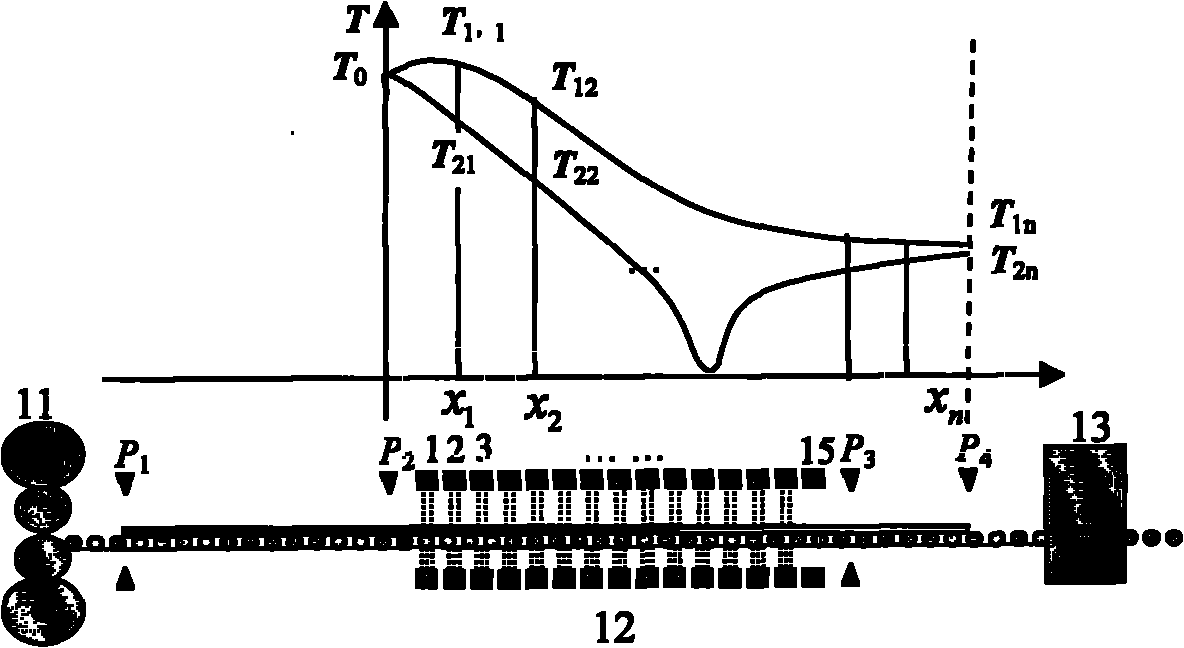

[0075] Such as figure 1 , figure 2 As shown, there are 15 sets of headers in the water cooling area of a medium and thick plate accelerated cooling production line. where T p1 for P 1 Point temperature measurement; T p2 for P 2 Point temperature measurement; T p3 for P 3 Point temperature measurement; T p4 for P 4 point temperature measurement. In thick plate with P 2 and P 4 As the boundary, the upper and lower surfaces of the steel plate are used as the upper and lower boundaries. Matter flows from left to right, and the arrows indicate the direction of energy flow.

[0076] Such as figure 2 As shown, the spacing between each set of headers is 1.6 meters, the coordinates of the entrance of the cooling zone are 65.48 meters, and the coordinates of the first laminar flow header are 71.88 meters. Temperature detector P 2 The distance from the first set of headers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com