Damping device with disk spring assembly structure

A disc spring and shock absorbing device technology, applied in the field of shock isolation devices and building shock absorption, to reduce economic losses, improve social benefits, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

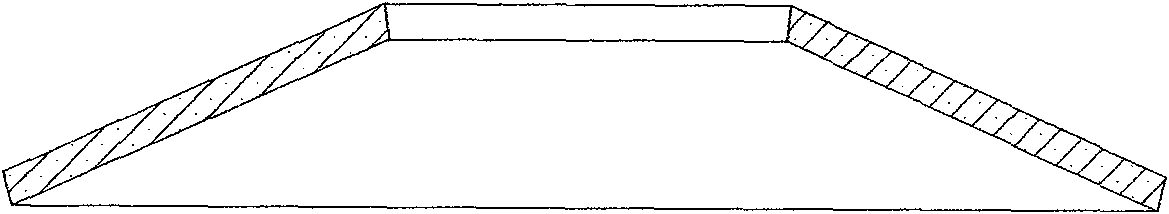

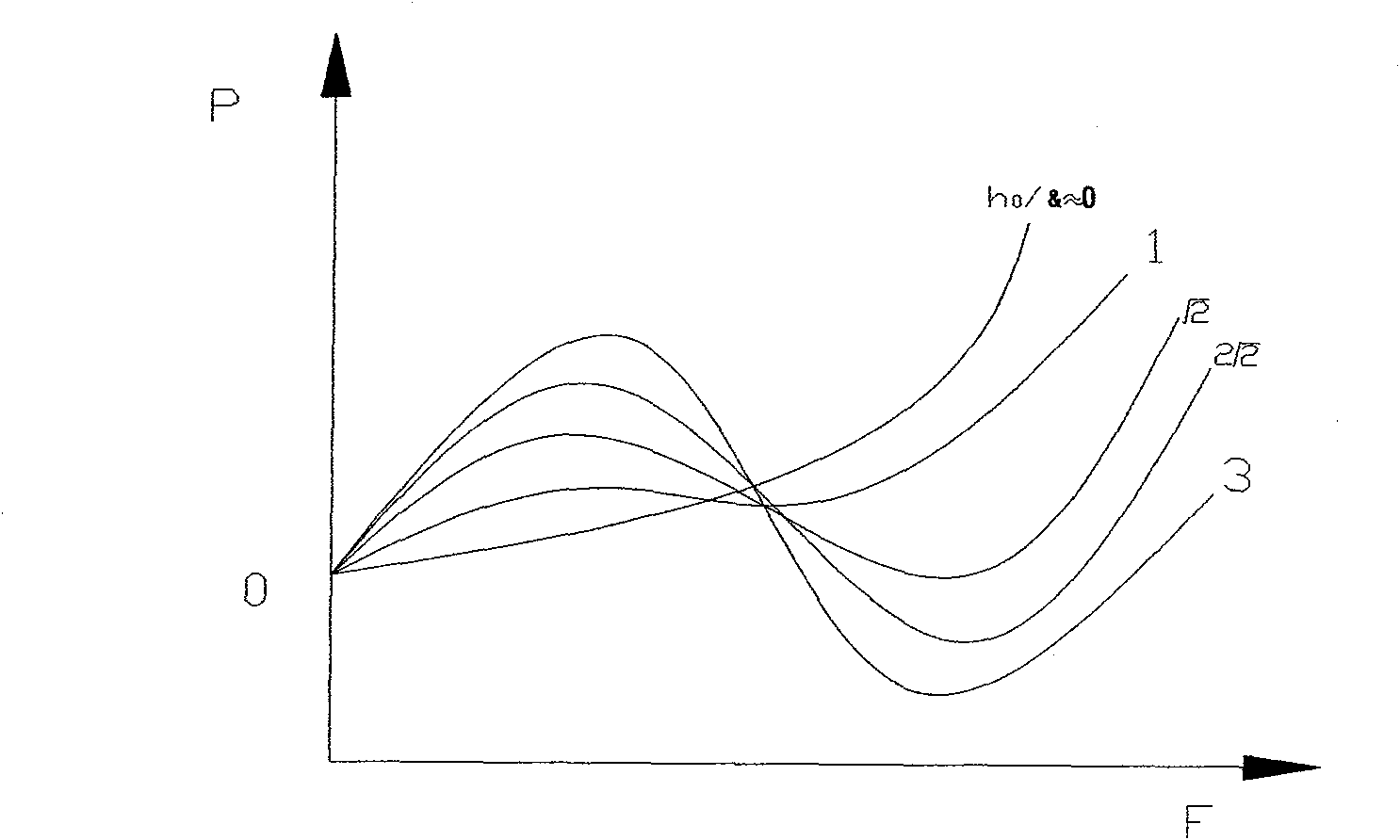

[0018] refer to figure 1 , figure 2 As shown, the disc spring is flat, and the linear relationship of the load-deformation characteristic curve shows that the bearing capacity is large, which is very suitable for the occasions with compact axial space, wide lateral space and heavy load. Using the principle of resonance, the disc spring The spring constitutes the vertical base isolation system, and the vertical stiffness of the structure can be effectively reduced through reasonable parameter design to achieve the purpose of vertical isolation and shock absorption.

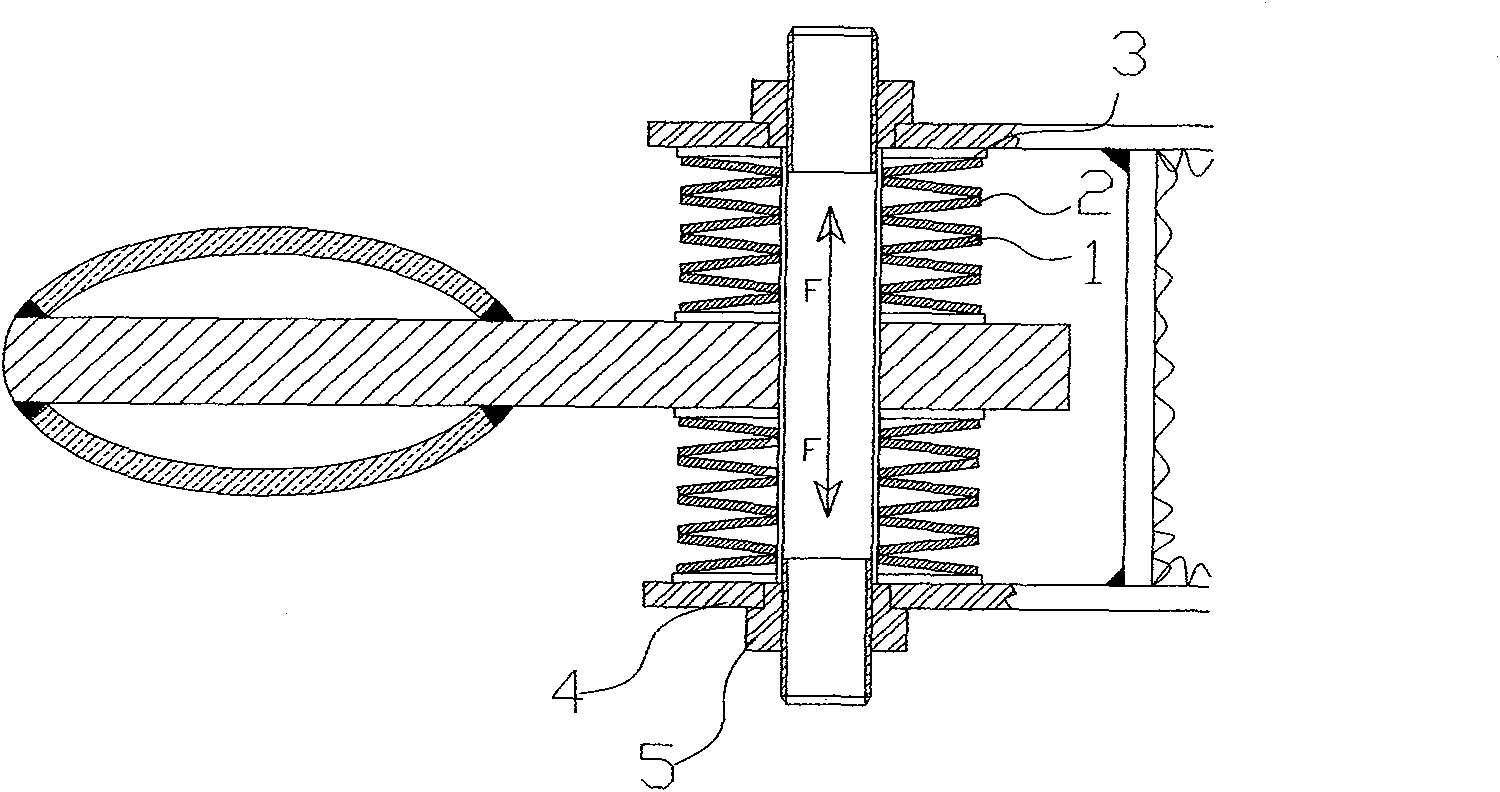

[0019] refer to image 3 , Figure 4 And specifically for the top connection node device and the bottom connection node device of Shanghai Oriental Art Center, a shock absorbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com