Rotary magnetic steel oil-filled type subducted permanent magnet synchronous motor rotor

A permanent magnet synchronous motor technology, applied in the field of motors, can solve the problems that the permanent magnet synchronous motor cannot guarantee the operation reliability, no collision, and hidden safety hazards, so as to ensure long-term normal operation and help save energy and reduce consumption , reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

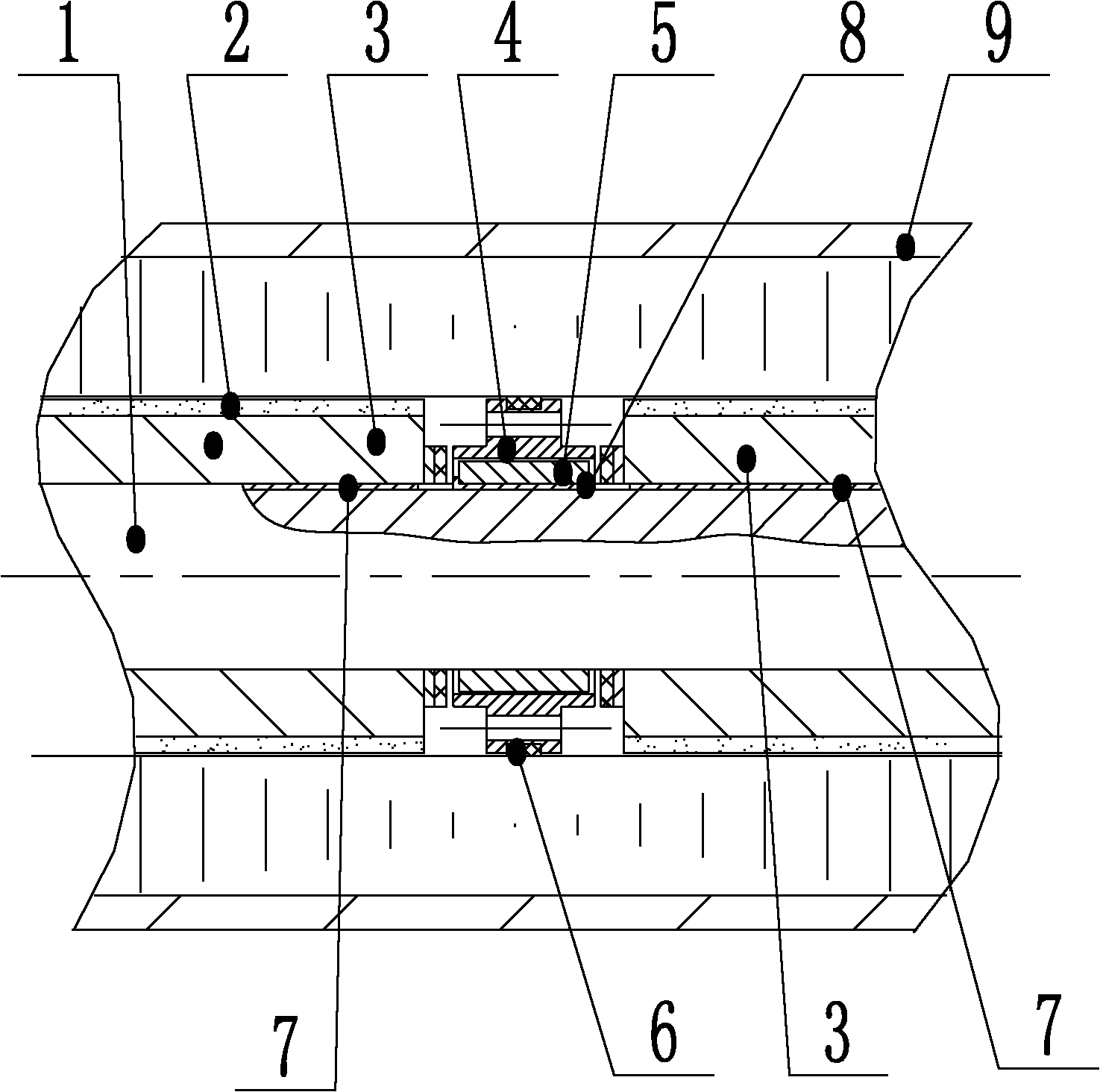

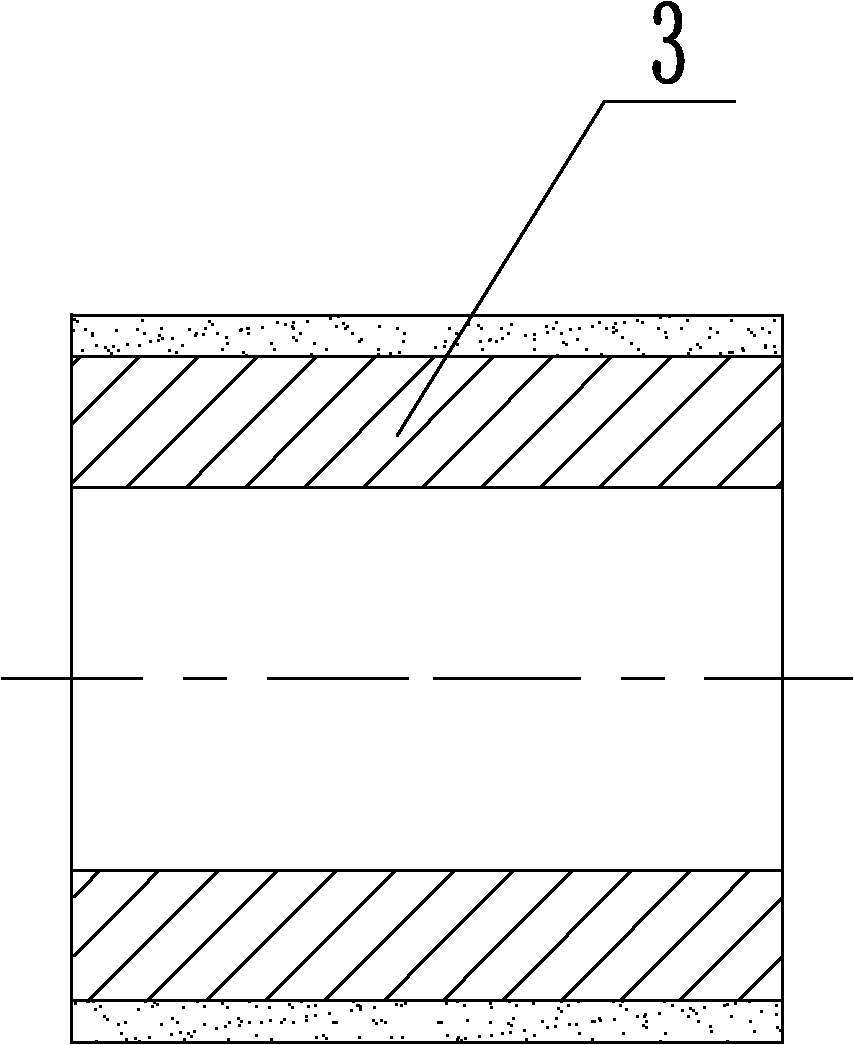

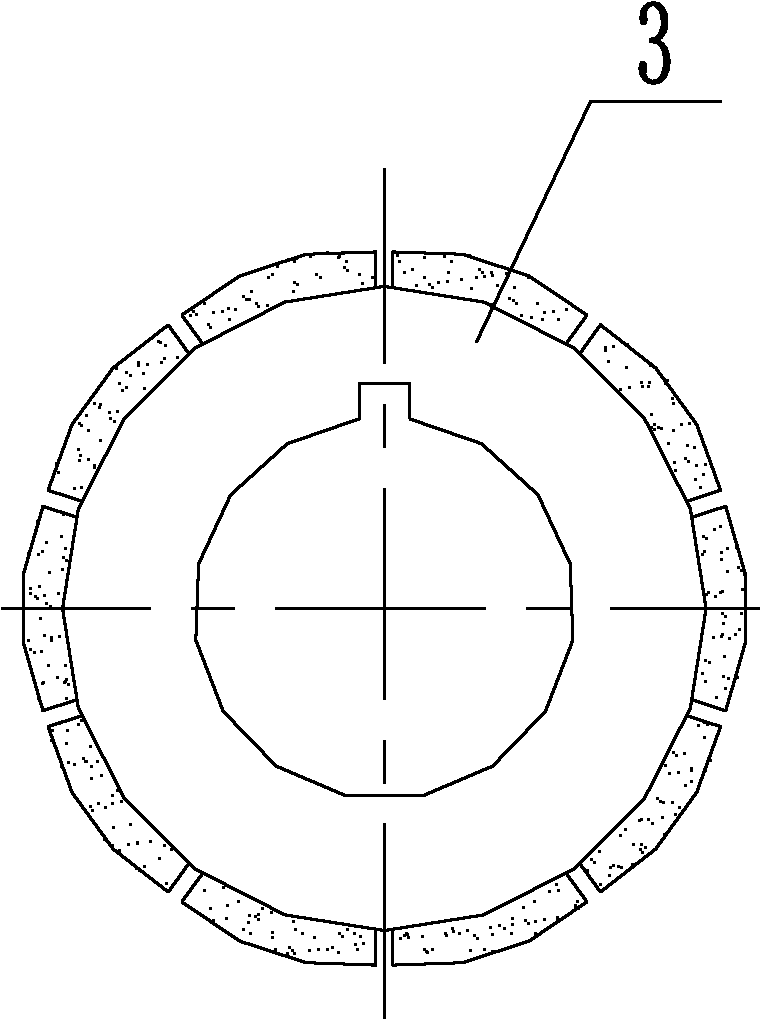

[0026] Refer to attached Figure 1 to Figure 5 .

[0027] A rotating magnetic steel oil-filled submerged permanent magnet synchronous motor rotor, characterized in that: the motor rotor is composed of several yokes 3 fixed with magnetic steel 2, and each yoke 3 is connected and fixed on a rotating shaft through a key 7 1, the magnetic steel 2 is fixed on the surface of the yoke 3. There is a rotating shaft centralizing mechanism between every two sections of yokes 3 . The rotating shaft righting mechanism is made up of bearing body 4 and bearing sleeve 5, and bearing body 4 and bearing sleeve 5 are relatively assembled together. The bearing sleeve 5 is fixed on the rotating shaft 1 through the key 8; the bearing body 4 is located outside the bearing sleeve 5, and the bearing body 4 cooperates with the stator core 9; the rotating shaft 1 drives the bearing sleeve 5 to rotate and forms a sliding bearing pair with the bearing body 4 . The outer ring of the bearing body 4 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com