Stress axis fixation method of polarization-maintaining fiber

A polarization-maintaining optical fiber and axis-fixed technology, which is applied in the direction of polarized optical fiber, clad optical fiber, light guide, etc., can solve the problems of large extinction ratio loss, difference in stress direction, and reduced device performance, so as to improve accuracy and increase extinction ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The features of the present invention and other relevant features will be described in further detail below through embodiments in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

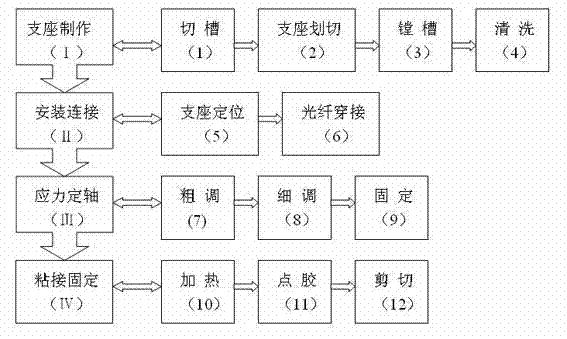

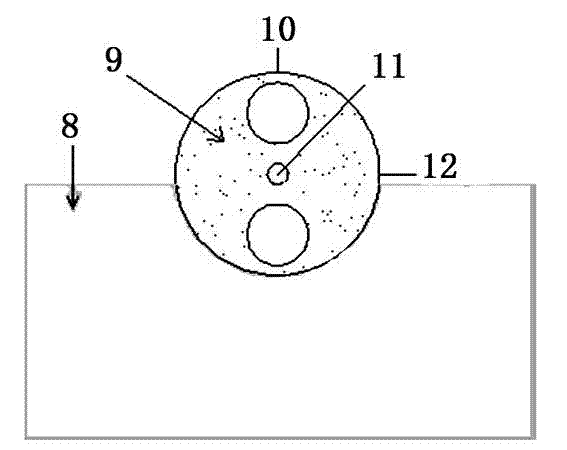

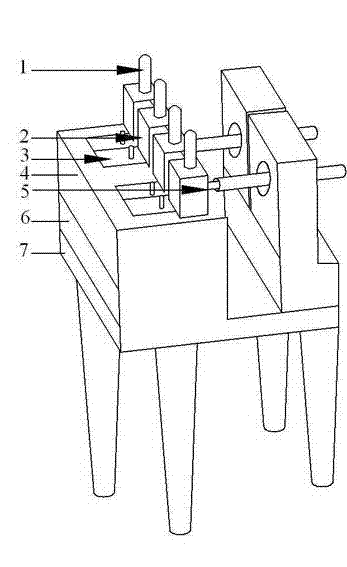

[0022] Such as Figure 1-3 As shown, the labels respectively indicate: positioning pin 1, pressing block 2, card 3, heater 4, adapter 5, heat shield 6, base 7, optical fiber support 8, polarization maintaining optical fiber 9, slow axis 10, core 11, Fast axis 12.

[0023] The basic principle of the present invention is as follows: by passing linearly polarized light with a high extinction ratio into one end of the polarization maintaining fiber 9 and inserting an extinction ratio meter into the other end, the extinction ratio can be displayed in real time. Then remove the organic cladding of the polarization-maintaining fiber near the end of the extinction ratio meter, and apply a certain pressure to it. If the direction of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com