Extra-high voltage alternating current non-contact multi-channel electricity testing method

A UHV AC, non-contact technology, applied in the measurement of electrical variables, measuring devices, instruments, etc., can solve the problems of large interference of live equipment, low accuracy, electrical inspection reference value and alarm threshold easily susceptible to external interference, etc. Achieve the effect of solving poor repeatability and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

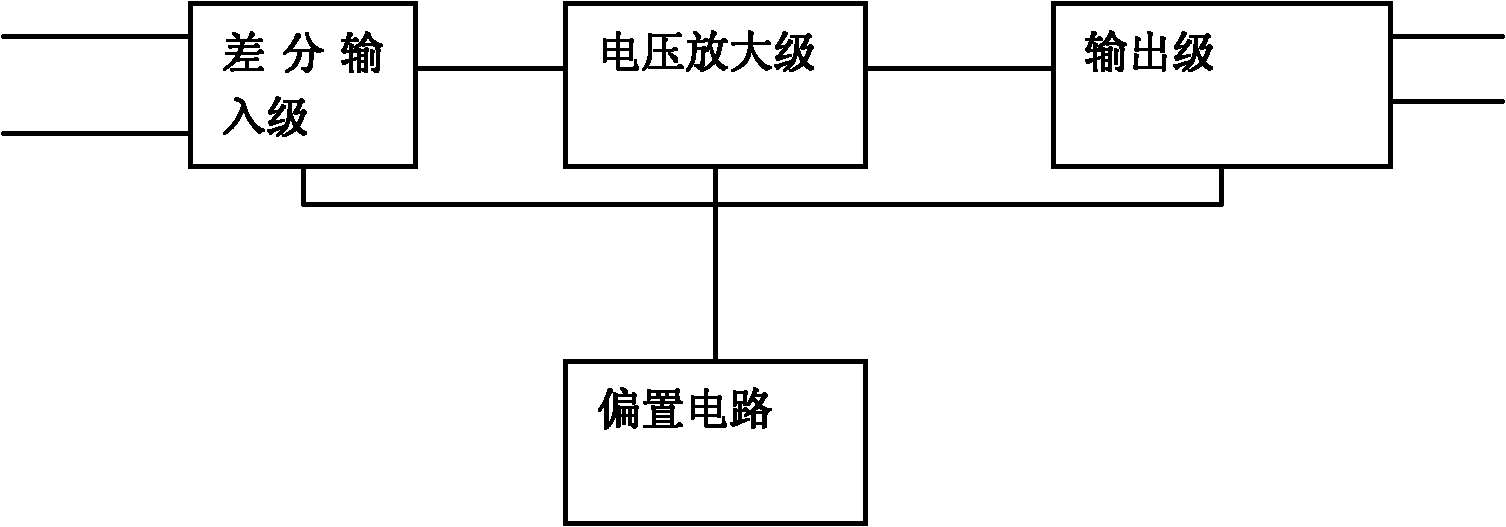

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

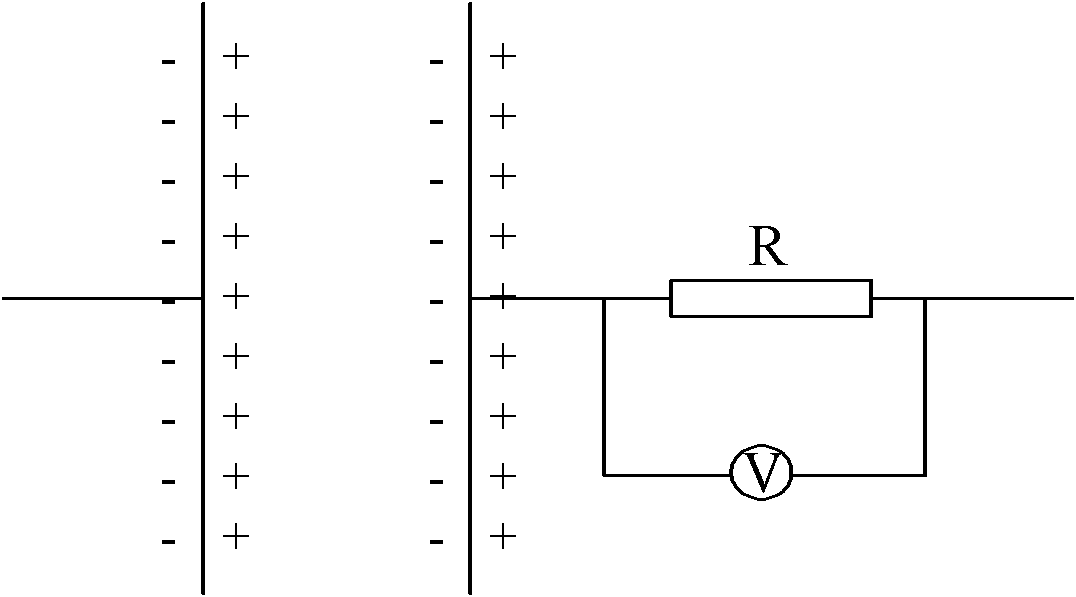

[0023] 1. Measure in the line

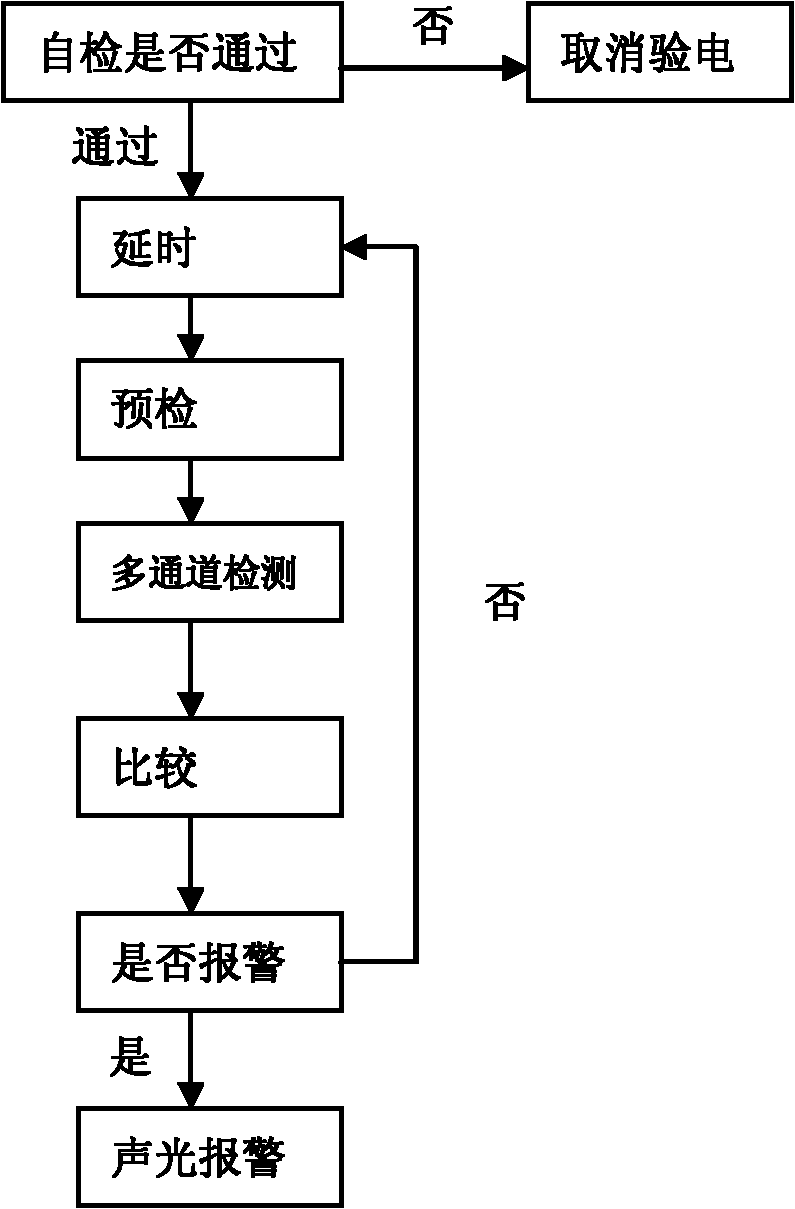

[0024] First, select a suitable measurement point A, turn on the electroscope, and perform a self-inspection first; when the electroscope is confirmed to be working normally, conduct an electroscope.

[0025] Place it at a place below 20cm from the ground to collect the field strength value. As a factor of the alarm threshold, the horizontal channel value of the electroscope at this time is V 1 =0.52, the vertical channel value is H 1 = 0.48. Then according to the procedure, V 1 with H 1 The value is compared, the larger one is used as the alarm threshold factor, and the alarm threshold is T=V 1 ×3.8 (3.8 is the multiplication factor obtained from multiple circuit tests, depending on the specific situation), that is, 1.976.

[0026] Then install the electroscope on the insulating operating rod, use the insulating operating rod to push the electroscope to a place more than 3 meters above the ground, and collect the field strength value. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com