Double control fuel mixing chamber and separation flame plate

A technology of fuel mixing and flame disc, which is applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of rich oil, large or small air flow, easy carbon deposition, etc., and achieve high temperature, small volume, and easy The effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

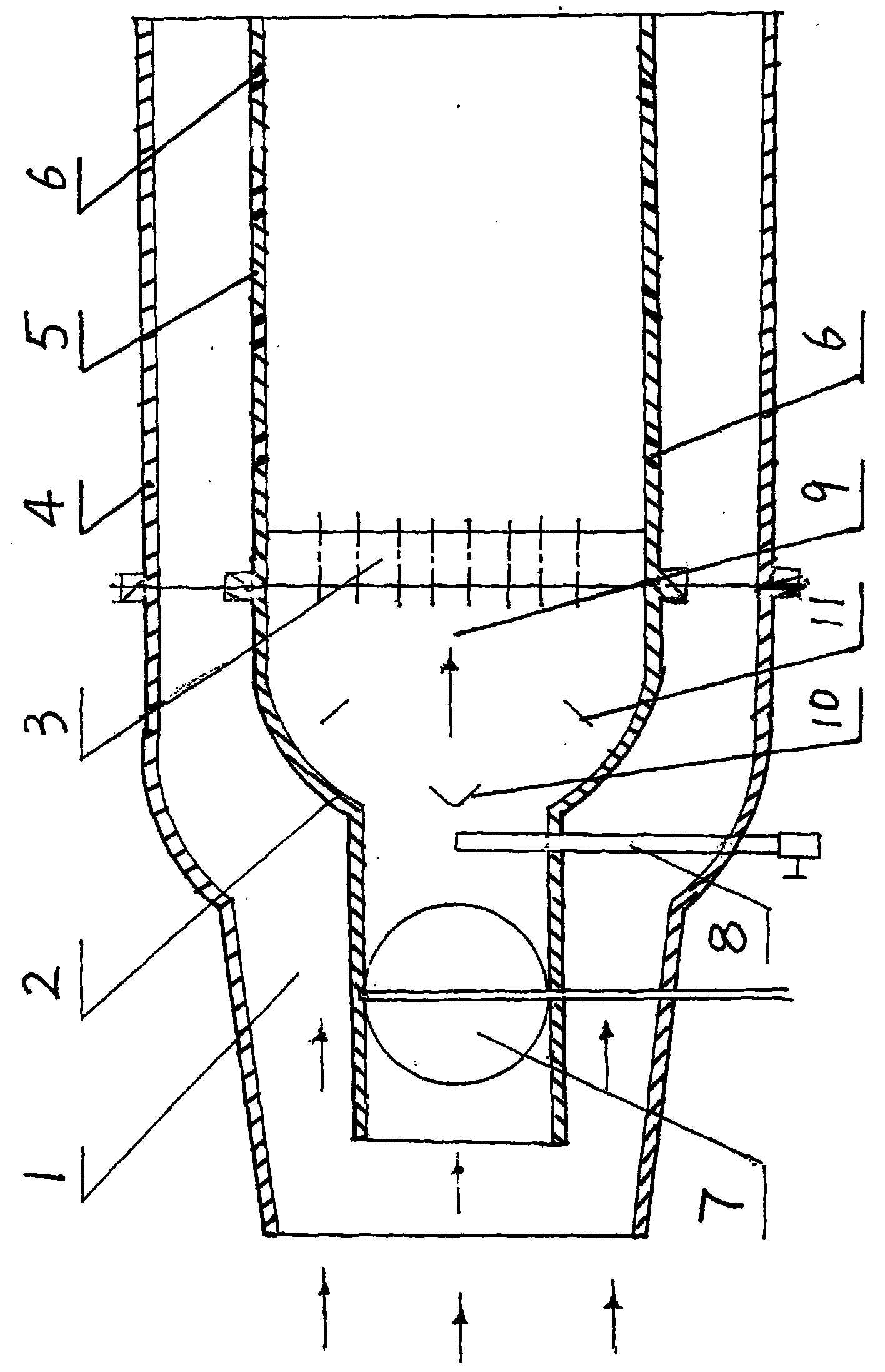

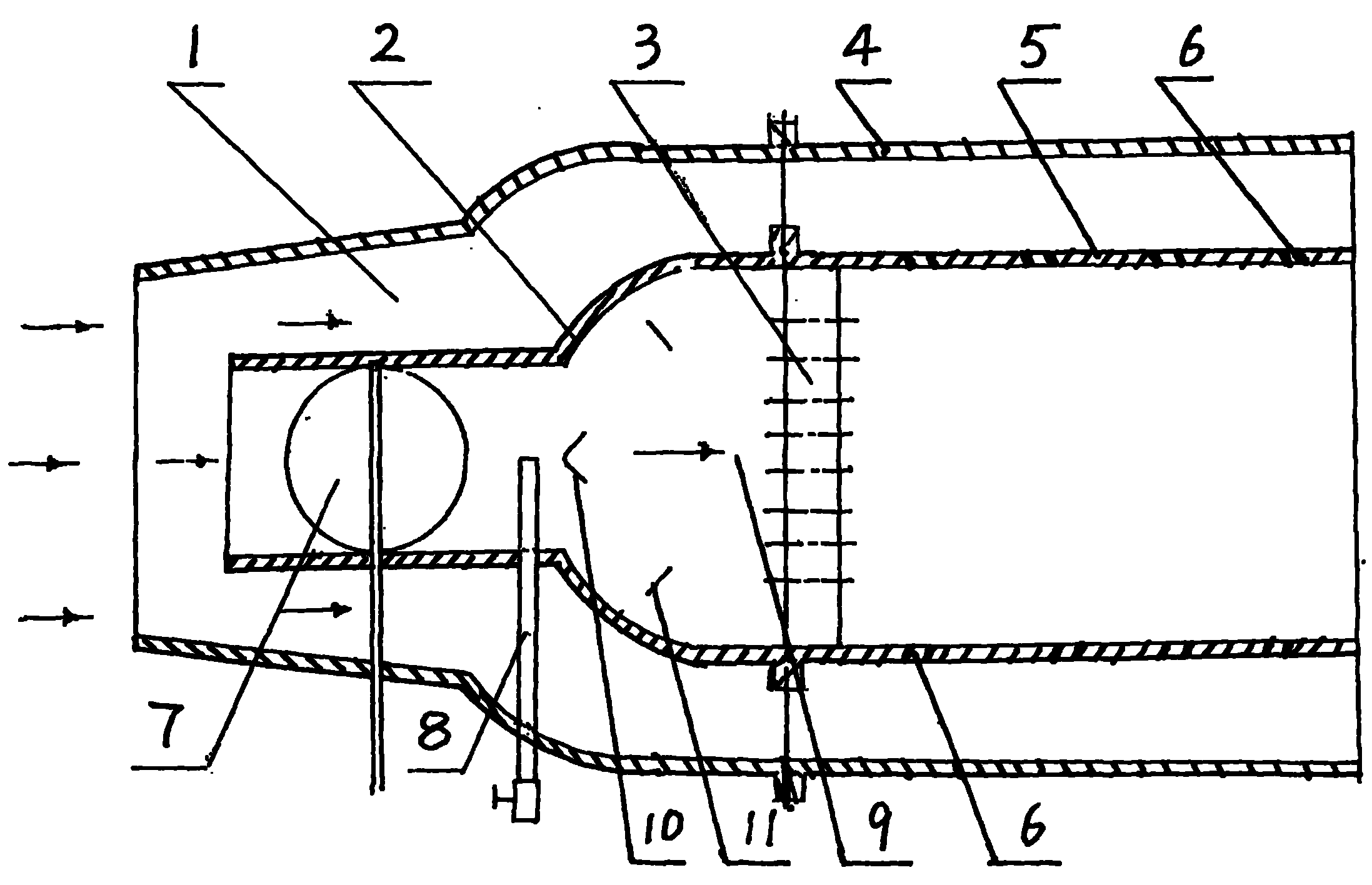

[0012] Such as figure 1 shown. The present invention is composed of a mixing chamber 2, a valve 7 with adjustable compressed air flow rate, a gas dividing plate 10, a gas gathering plate 11, and a fuel pipe 8. The mixing chamber 2 is made of conductive material. Flame tube 5 is made of high temperature resistant material. The valve 7 is located at the neck of the mixing chamber 2 to adjust the intake volume of the high-speed compressed air in the mixing chamber so that the gas and fuel value can reach 1, and the high energy speed and low speed can be controlled. The bell mouth section of the mixing chamber 2 is a mixing area, and two gas side discs 10 are arranged at the front and rear positions of the central axis of the mixing chamber 2. The gas side discs 10 are conical cover bodies, which can guide the airflow to the surroundings. The converging disc 11 is an annular conical cover, connected to the mixing chamber 2 through a bracket, and matched with two gas side discs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com