Backlight module

A backlight module and light guide plate technology, applied in optics, light guides, light sources, etc., can solve problems such as troublesome assembly, long time, and inaccurate screw alignment, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the backlight module proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Details are as follows.

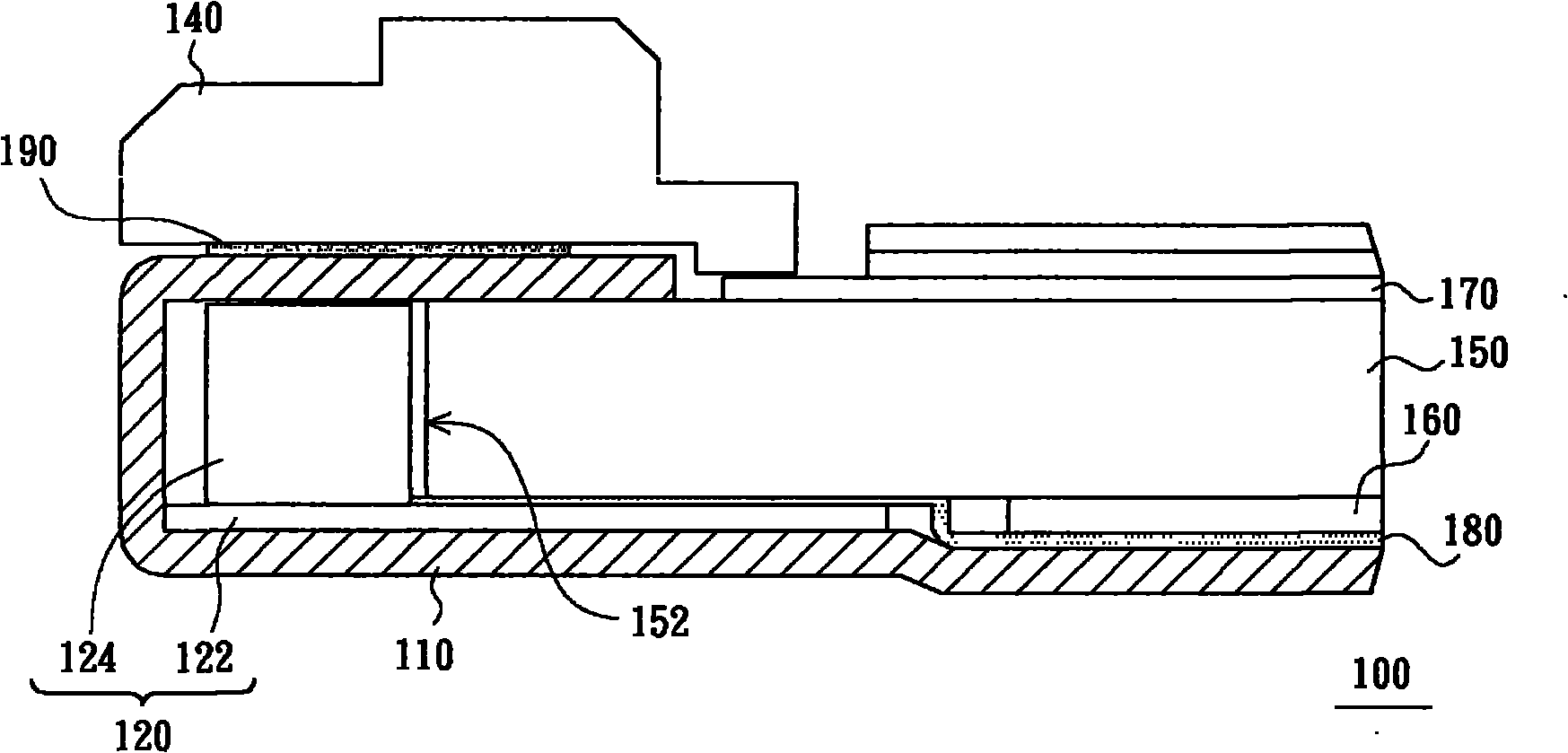

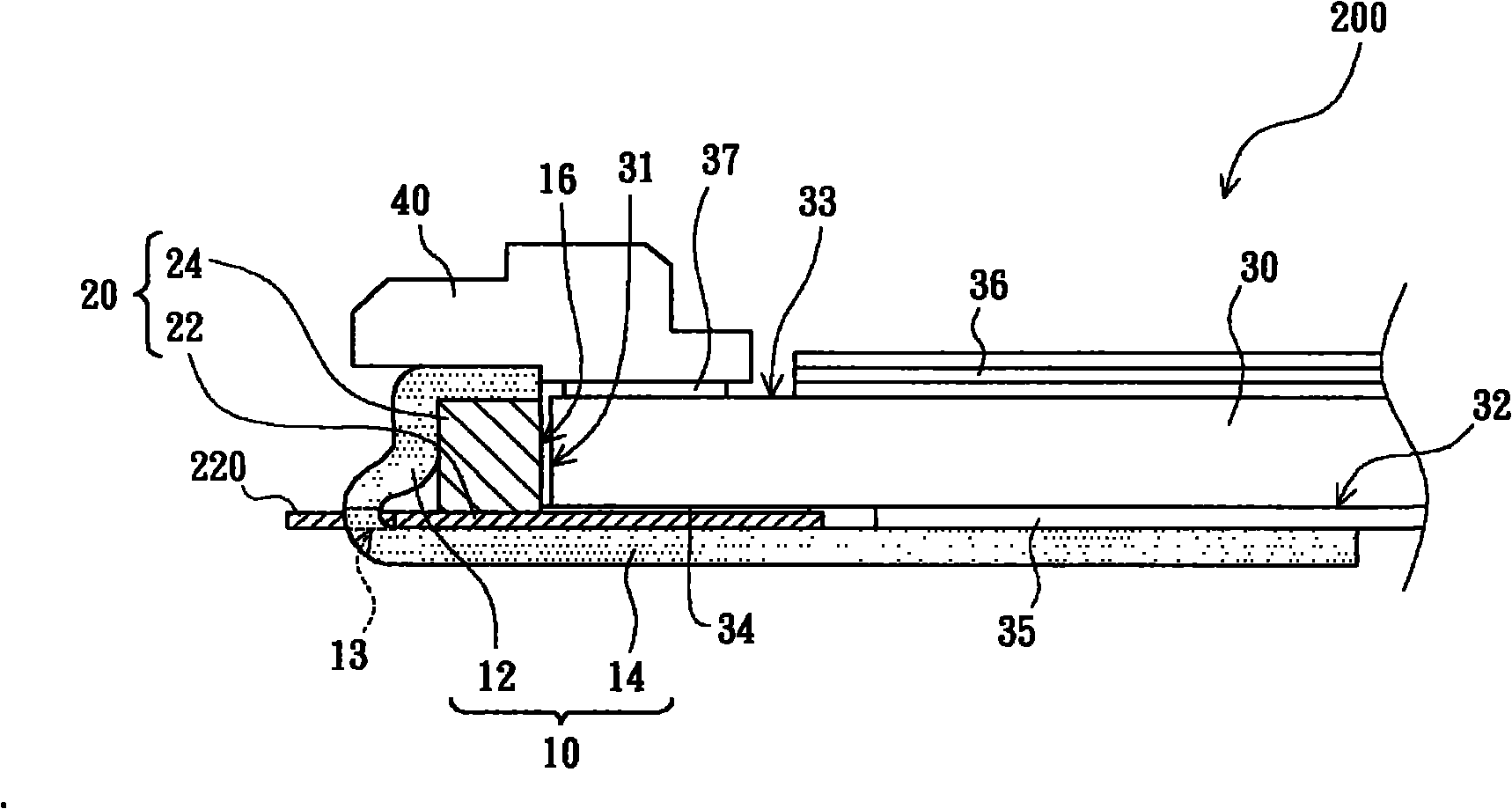

[0034] figure 2 It is a schematic diagram of a backlight module provided by an embodiment of the present invention. refer to figure 2 , The backlight module 200 provided by an embodiment of the present invention includes a reinforcing tape 10 , a light source assembly 20 and a light guide plate 30 .

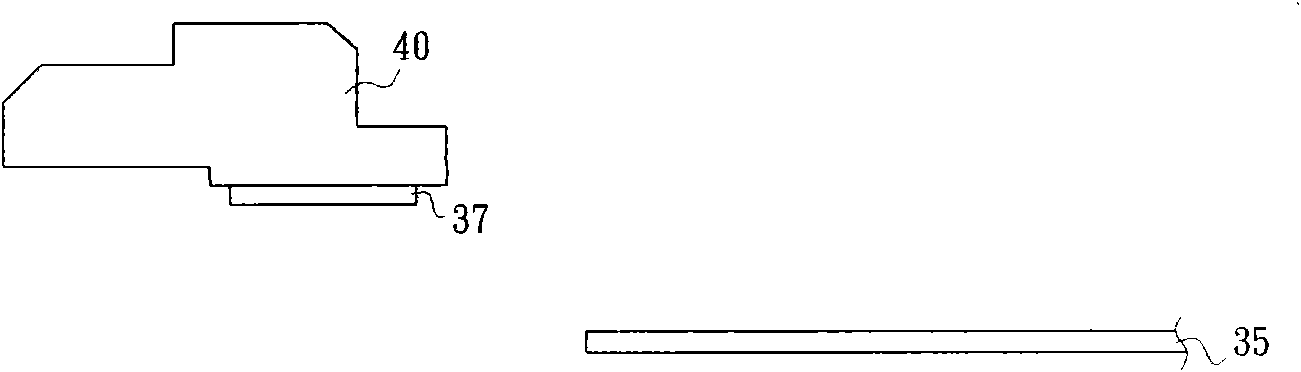

[0035] The reinforcing tape 10 is bent to form a cover body 12 and a support portion 14 extending from the bottom of the cover body 12 , wherein the cover body 12 has an opening 16 . The light source assembly 20 is pasted on the cover body 12 and located inside the cover body 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com