Manual double-cylinder residue discharging pump of biogas pool

A technology of slag pump and biogas digester, which is applied in the field of industry, can solve the problems of power consumption, time and resource waste, etc., and achieve the effects of reducing power load, easy operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

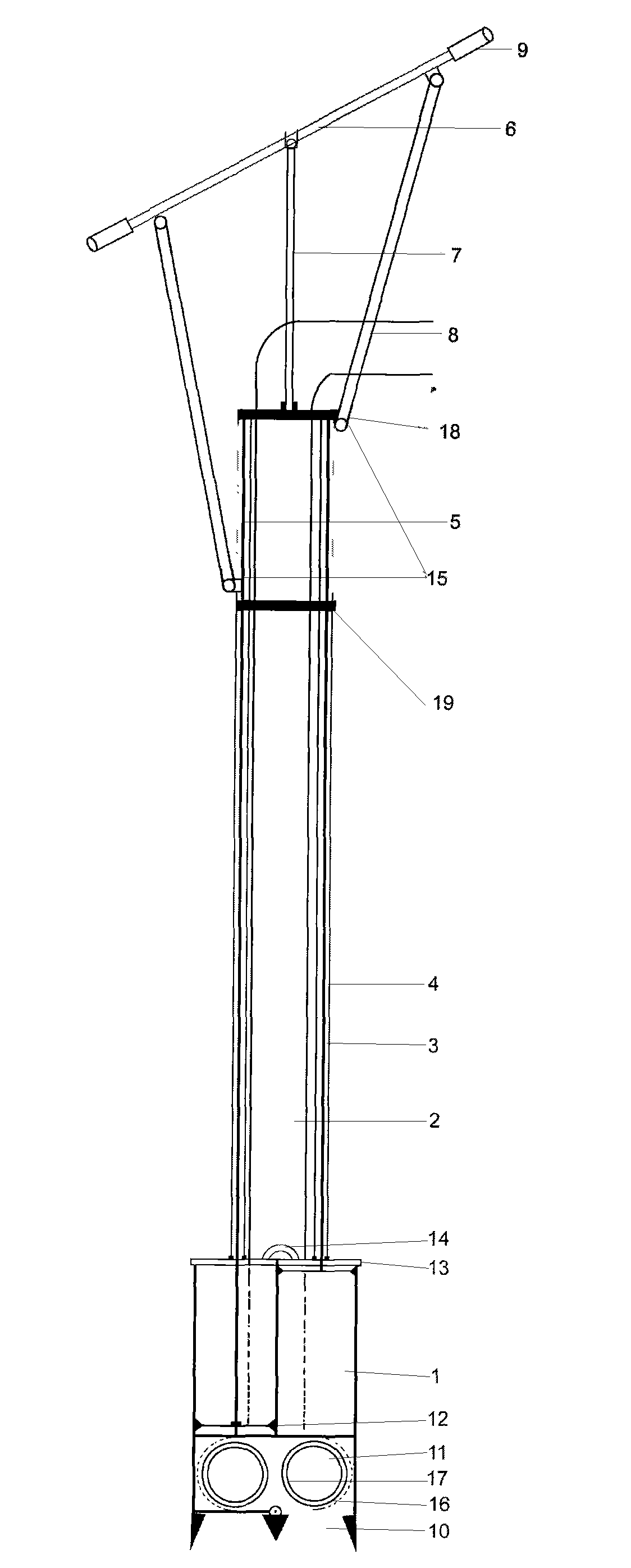

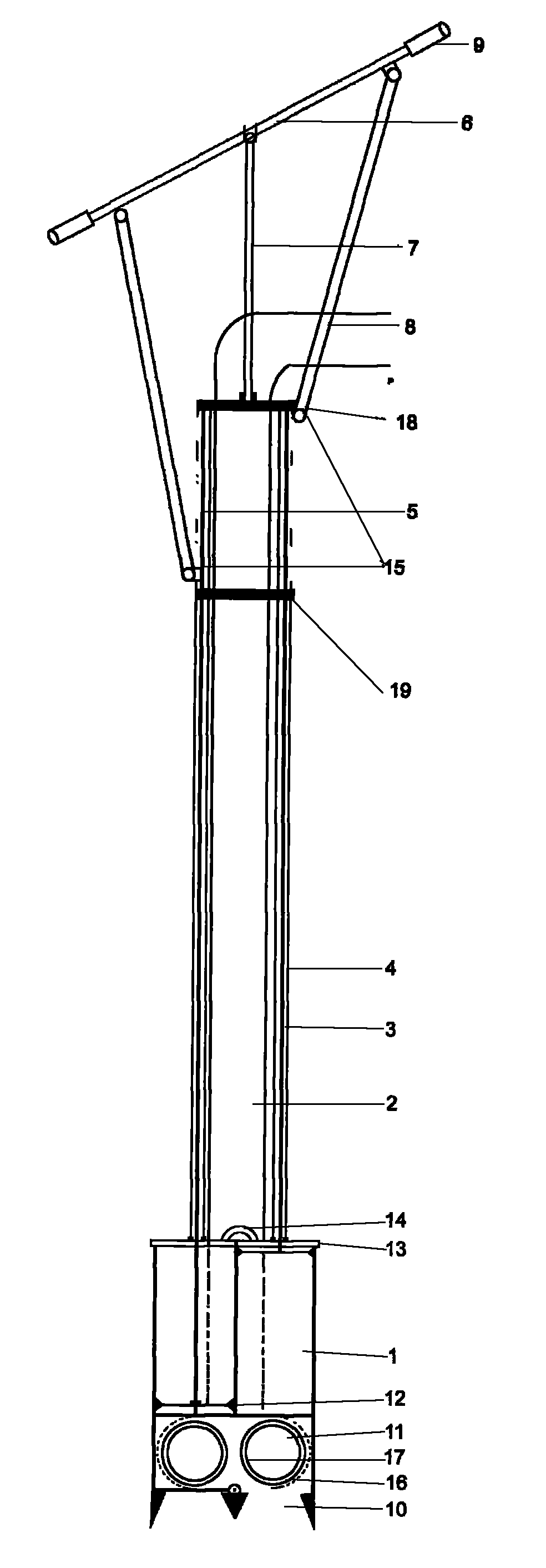

[0007] Specific implementation mode one: combine figure 1 Explain that the embodiment of the biogas pit manual double-cylinder slag pump includes a pump body 1, a slag pipe 2, a slag pressing rod 3, a power rod 6, an internal valve 16 connected to an external valve 17. The slag pressing rod 3 It passes through the casing 4 , the upper end is connected with the traction member 8 , and the lower end is connected with the piston 12 . The lower end of the casing 4 is connected to the pump body upper cover 13, and the upper end is a slideway 5, and the slag pressing rod 3 is driven to move up and down in the slideway 5 by the traction member 8 through the movable connecting shaft 15.

specific Embodiment approach 2

[0008] Specific embodiment two, combine figure 1 Explain, the lower end of the pump body 1 in the embodiment of the manual slag discharge pump for biogas digesters is the pump body leg and the slag inlet 10, and the side of the lower end is the slag outlet 11, so that the biogas residue is easily pressed out of the pump body 1, and the slag discharge efficient.

specific Embodiment approach 3

[0009] Specific embodiment three, combine figure 1 To illustrate, in the embodiment of the biogas pit manual double-cylinder slag pump, the slag inlet 10 is controlled by the integrated internal valve 16, which is installed in the slag inlet 10, and the relative angle of the two valves is 91°-179°. The slag outlet 11 is controlled by the connecting external valve 17 to control the reflux of biogas residue. The connecting external valve 17 is installed outside the slag outlet 11, and its structure and angle are the same as that of the connecting internal valve 16. When working, because the two valves are connected together and have a certain angle, the inner valve of the left cylinder opens, the outer valve closes, and the biogas residue is sucked into the pump body. At the same time, the inner valve of the right cylinder must be closed, and the outer valve suddenly opens. , to press the biogas residue out of the pump body, so set up, can cooperate with each other, save time a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com