Preparation method of dipropylene glycol methyl propyl ether

A technology of dipropylene glycol methyl propyl ether and dipropylene glycol monomethyl ether, which is applied in the field of preparation of dipropylene glycol double ether, can solve the problems of difficult separation, poor reactivity, low purity, etc., and achieves simple production operation, reduced production cost, and shortened time. The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

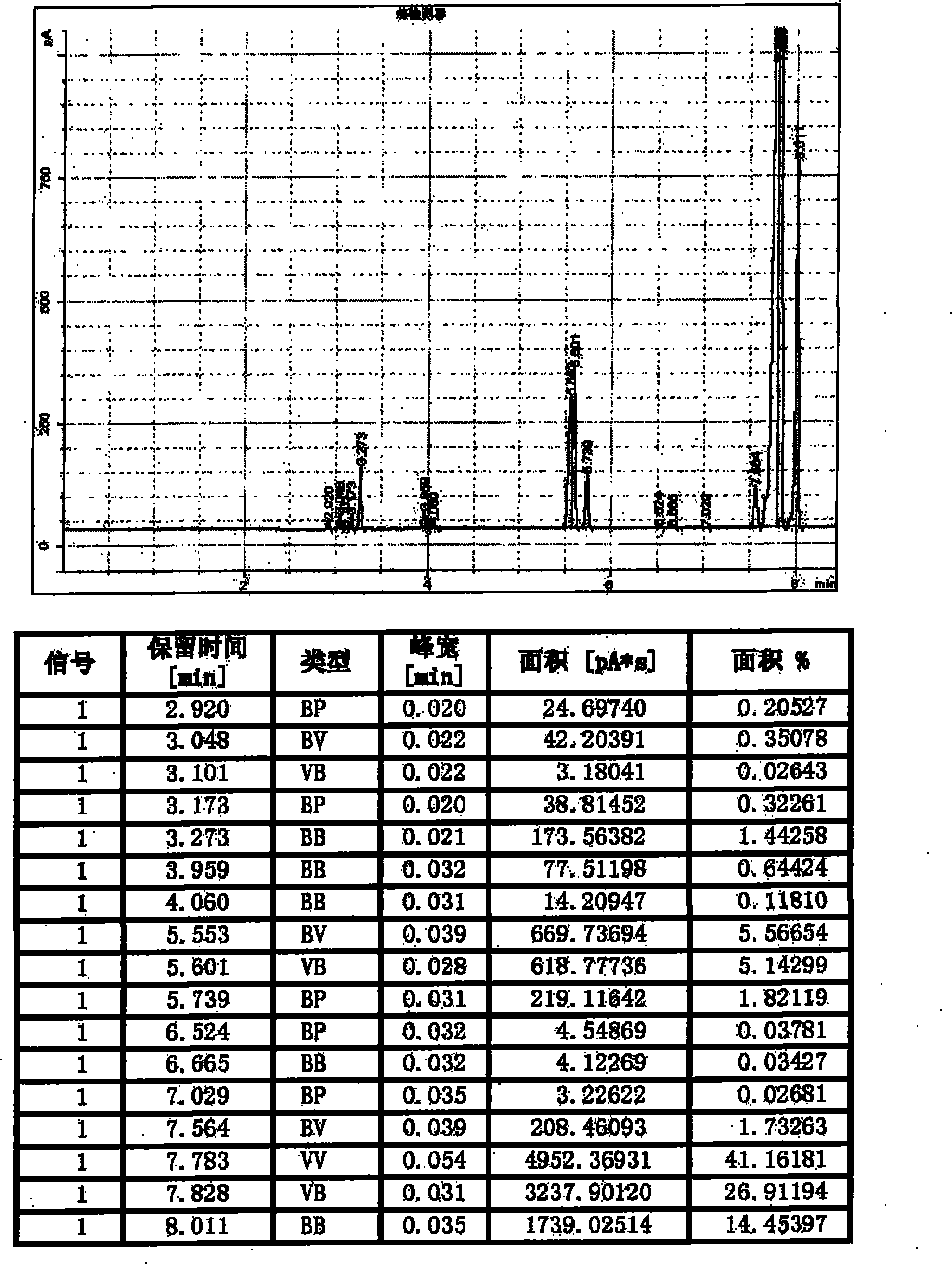

[0032] Add 148 parts of dipropylene glycol monomethyl ether into a 500ml four-neck bottle, add 60 parts of sodium hydroxide, raise the temperature to 50°C and stir for 30 minutes, then raise the temperature to 60-80°C, and drop chloropropane from the dropping funnel 100 parts, drop in about 2 hours, after the drop, raise the temperature to 80-100°C to react for 6h, then cool down to below 40°C, filter out the salt, and obtain 180.7g of organic matter in the upper layer, which is analyzed by gas chromatography (see attached figure 1 ), wherein the dipropylene glycol methyl propyl ether content is 84.26%, the unreacted raw material dipropylene glycol methyl propyl ether content is 12.53%, and chloropropane is 1.44%.

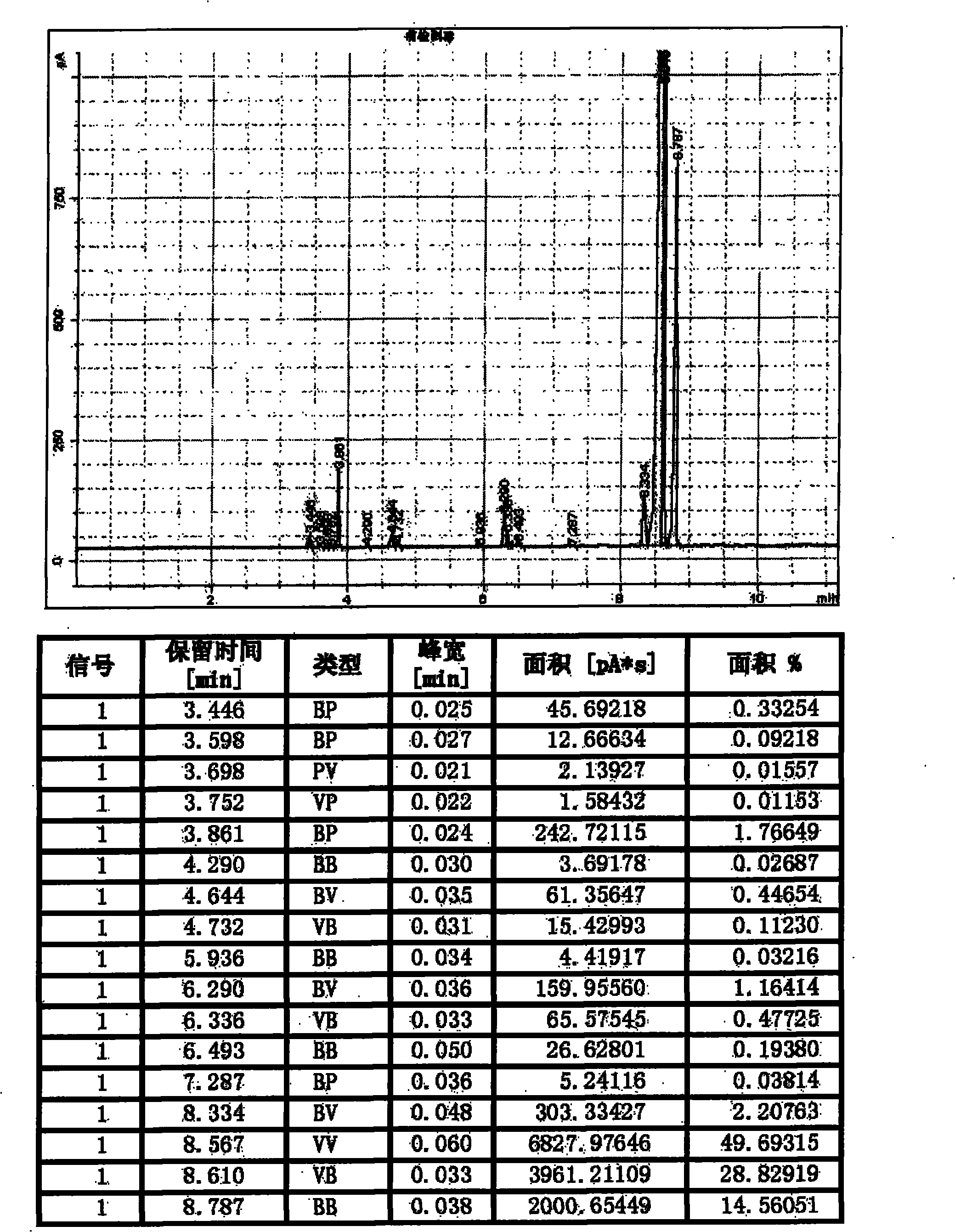

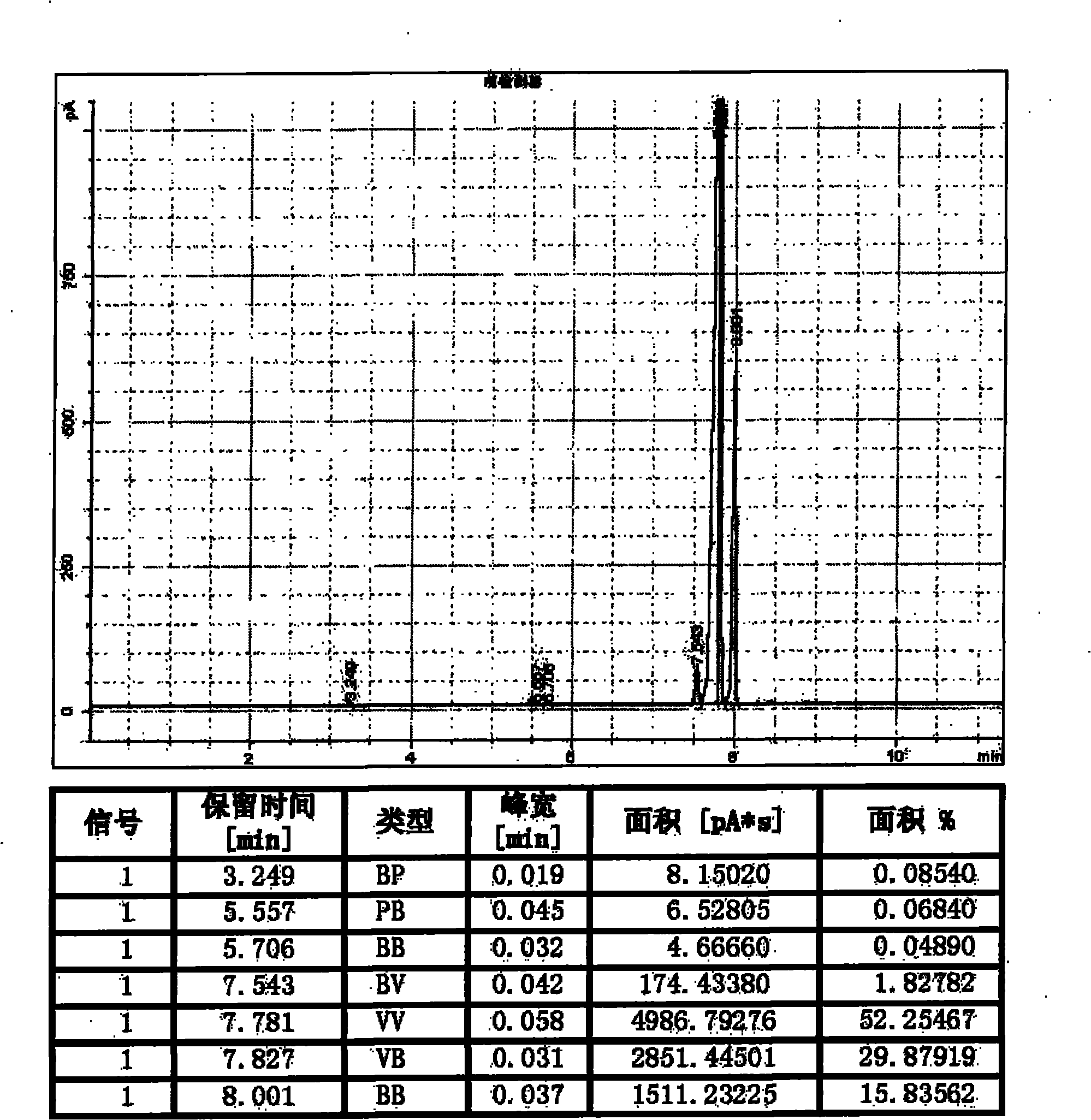

[0033] The product was poured into a 500ml separatory funnel. Add 100 parts of extractant (5% sodium chloride aqueous solution), shake fully and leave to separate for 2 hours, separate the lower water layer to obtain the upper product, which is analyzed by gas chro...

Embodiment 2

[0038] Change 100 parts of chloropropane in embodiment 1 into 150 parts of bromopropane, change the extractant into 50 parts, all the other are the same as embodiment 1, obtain dipropylene glycol methyl propyl ether 162.5g, content is 99.7%.

Embodiment 3

[0040] 60 parts of sodium hydroxide in embodiment 1 are changed into 100 parts of potassium carbonate, all the other are with embodiment 1, obtain dipropylene glycol methyl propyl ether 149.7g, and content is 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com