Thin walled tube welding method

A welding method and technology for thin-walled pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low strength and difficult positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

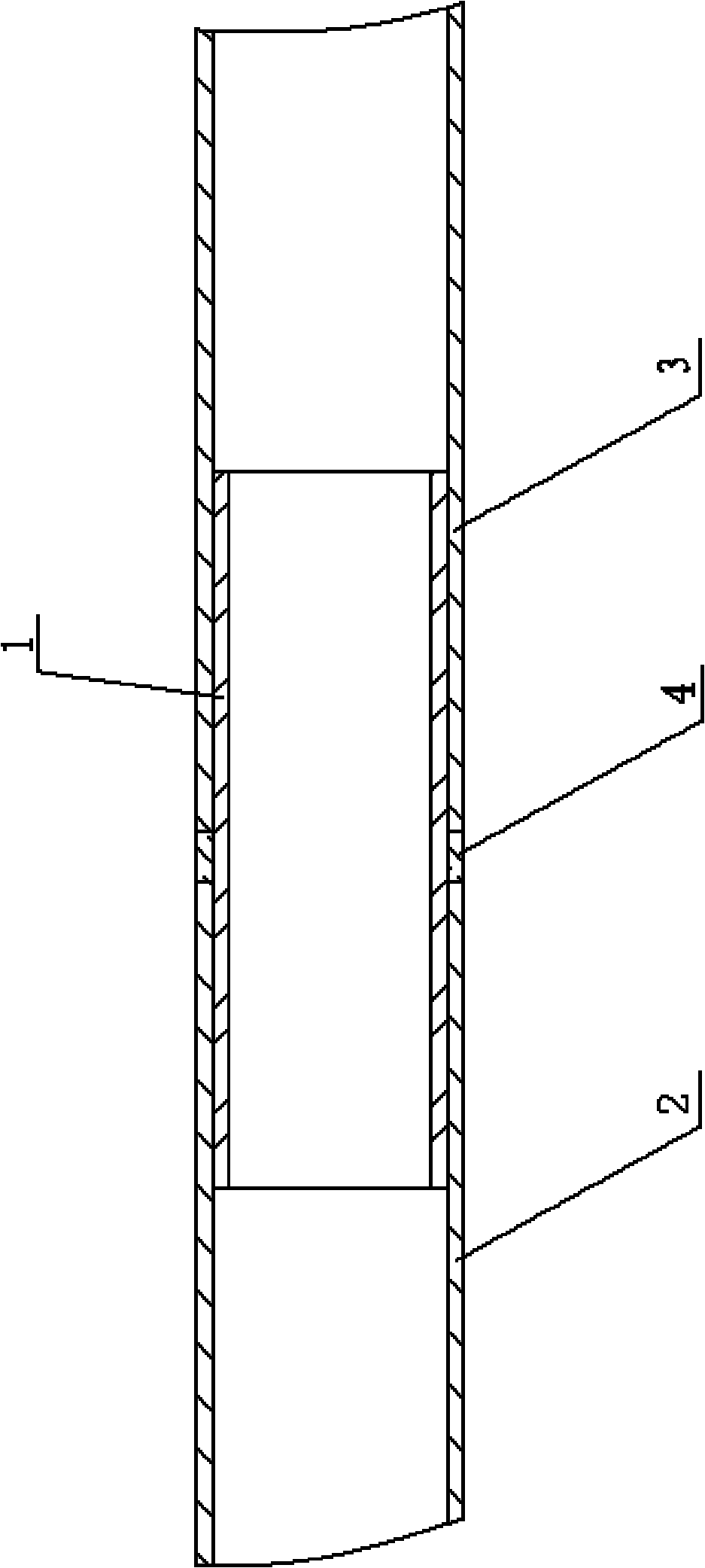

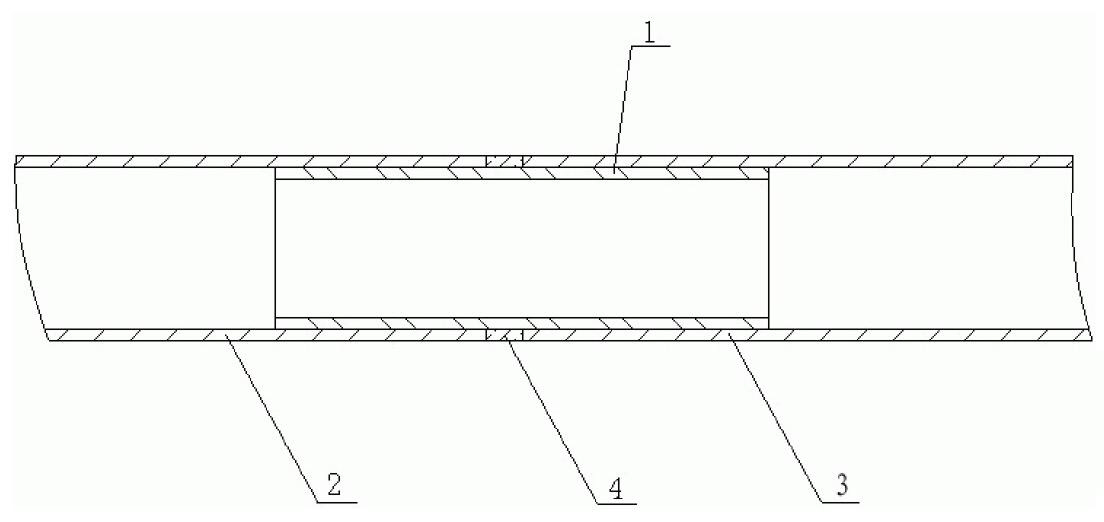

[0011] See figure 1 , which includes a liner 1, two thin-walled pipes 2, 3, the two ends of the liner 1 are respectively loaded into the inner holes of the two thin-walled pipes 2, 3 to be welded, and silver welding wire 4 is welded circumferentially between the liner 1 and the two thin-walled pipes. 2, 3 exposed places. The two ends of the liner 1 are screwed into the inner holes of the two thin-walled pipes 2 and 3 that need to be welded, or the two ends of the liner 1 are plugged into the inner holes of the two thin-walled pipes 2 and 3 that need to be welded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com