Vertical type fixed hydraulic power chuck

A hydraulic power and chuck technology, applied in the direction of chuck, clamping, positioning device, etc., can solve the problems that the power chuck and rotary cylinder system cannot be equipped, and the length of the clamping system itself is long, so as to achieve convenient and shortened clamping. Clamping time, the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

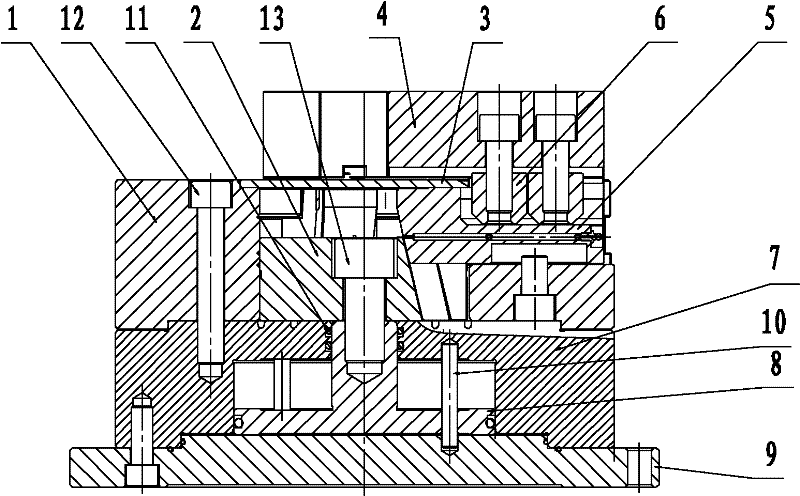

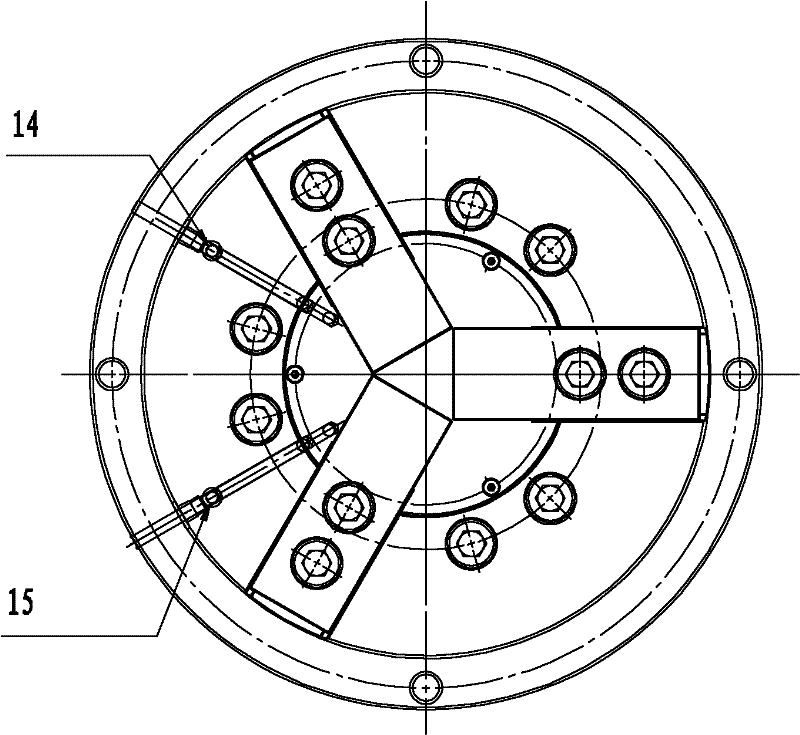

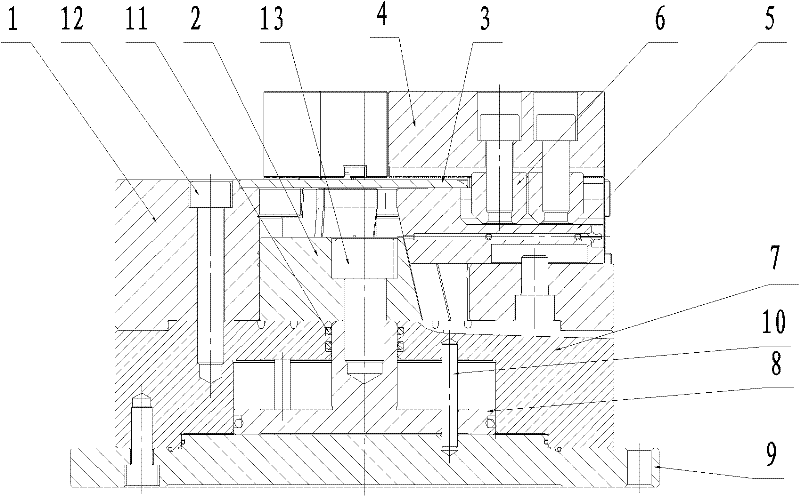

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0013] like Figure 1 ~ Figure 2 As shown, it includes chuck body 1, wedge sleeve 2, cover 3, three claws 4, three sliding seats 5, six T-blocks 6, cylinder body 7, piston 8, base 9, guide shaft 10 , Sealing ring 11, connecting screw 12, driving connecting screw 13, etc.

[0014] In the present invention, the chuck body 1 and the cover 3 are connected to form the chuck main body, and three straight grooves are provided at the front end of the chuck body 1, and three sliding seats 5 are installed in the three straight grooves, and the three sliding seats 5 pass through the chute and the wedge The core sleeve 2 is connected, and the sliding seat is connected to the three claws 4 through the comb teeth outside the front face of the disc body, and is fixed by six T-shaped blocks 6 and three claws 4 with claw mounting screws, and is connected with the wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com