New premix burner

一种预混燃烧、燃烧器的技术,应用在燃烧器、气体燃料燃烧器、燃烧方法等方向,能够解决燃烧器难制成等问题,达到气流顺畅、降低排放、火焰稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

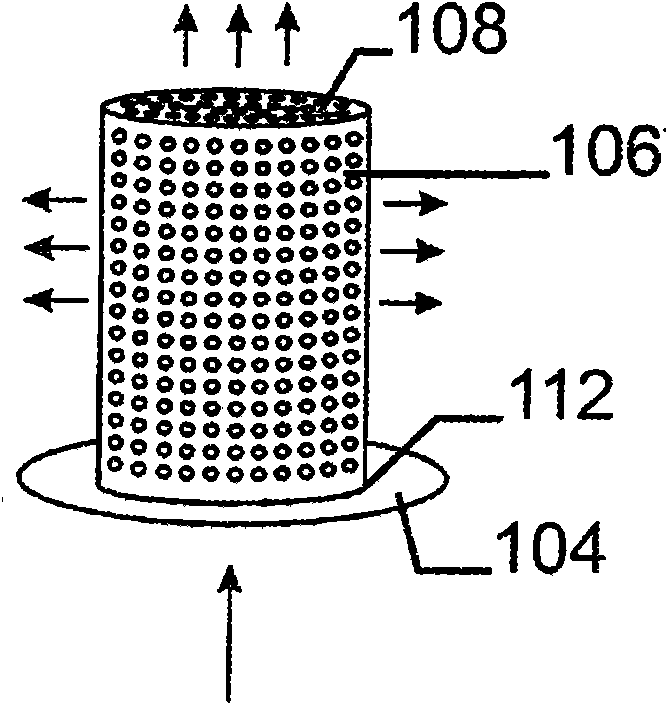

[0048] Figure 1a A cylindrical burner according to the invention is shown comprising a gas supply chamber 102 connected at the bottom to a support 104 . The bracket 104 has a central gas inlet for supplying gas into the gas supply chamber 102 . The gas supply chamber 102 is surrounded by a first burner membrane 106 on its side and a second burner membrane 108 opposite said gas inlet. The second burner membrane 108 is connected to the top of the burner membrane 106 . The burner membrane 106 is connected to the bracket 104 at the bottom. Arrows indicate flames generated in a direction generally perpendicular to the burner surfaces, thereby providing radial air flow at the first combustor diaphragm 106 and axial gas flow at the second combustor diaphragm 108 .

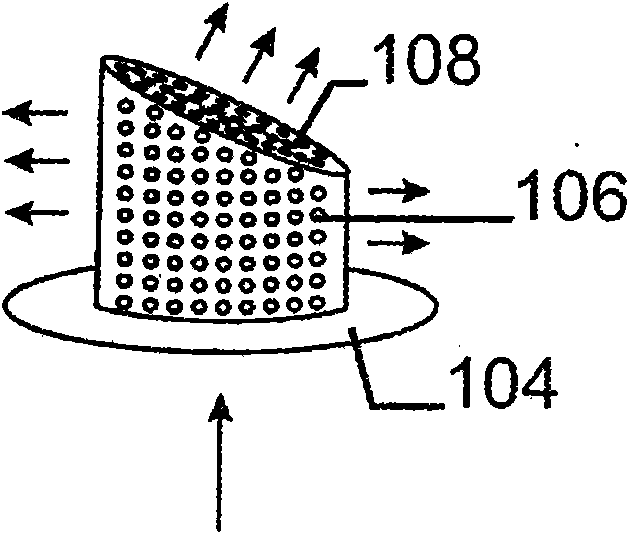

[0049] Figure 1b shows the same Figure 1a The illustrated burner is similar to a cylindrical burner, with the second burner diaphragm 108 forming a plane that intersects the first burner diaphragm 106 at an angle ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com