Control valve for a camshaft adjuster

A technology for controlling valves and ventilation valves, applied in valve devices, machines/engines, thin material handling, etc., can solve the problems of hindering the relative movement of components, expensive and improved filter manufacturing and assembly, and achieve good purification and enlargement. filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

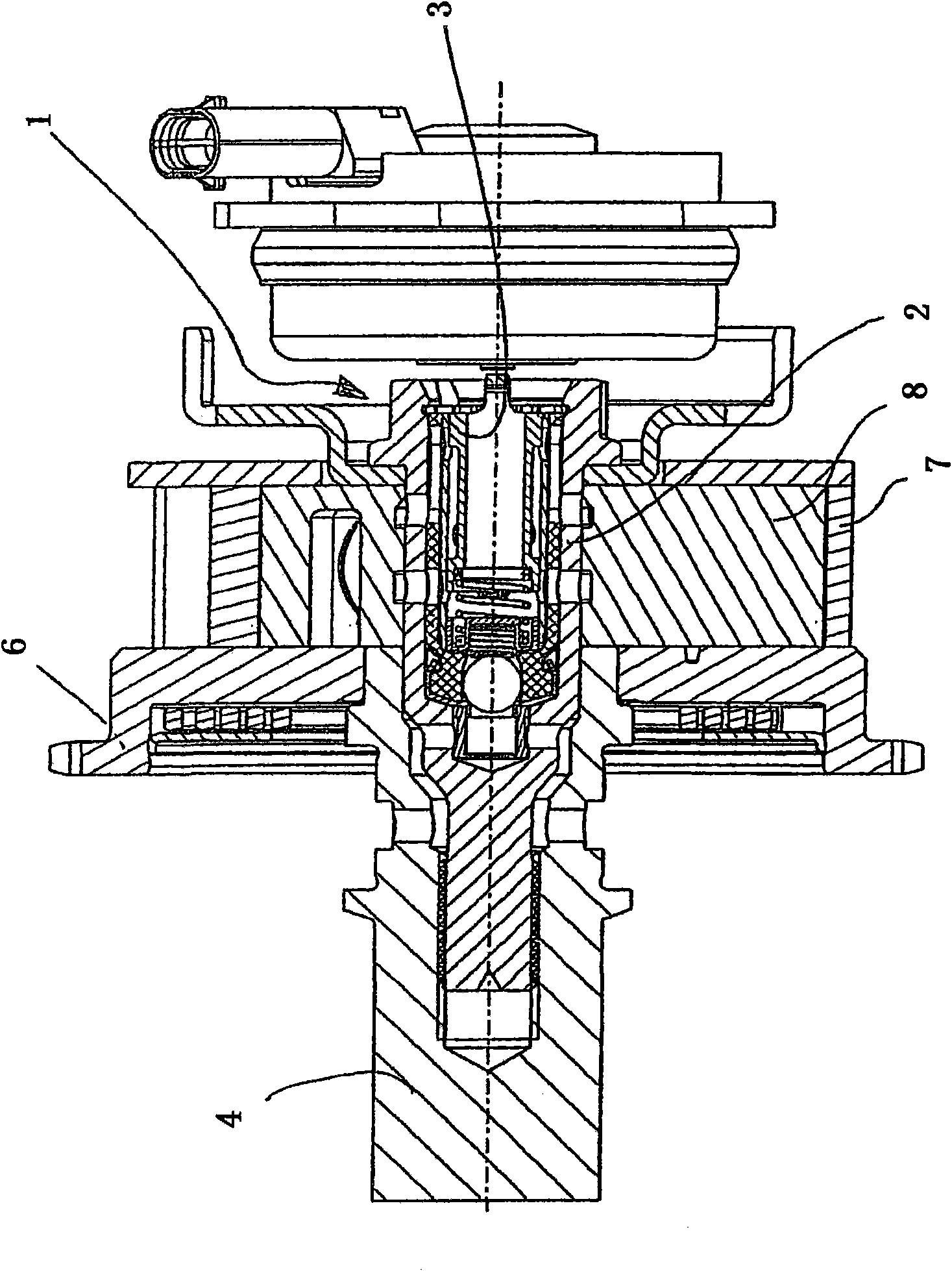

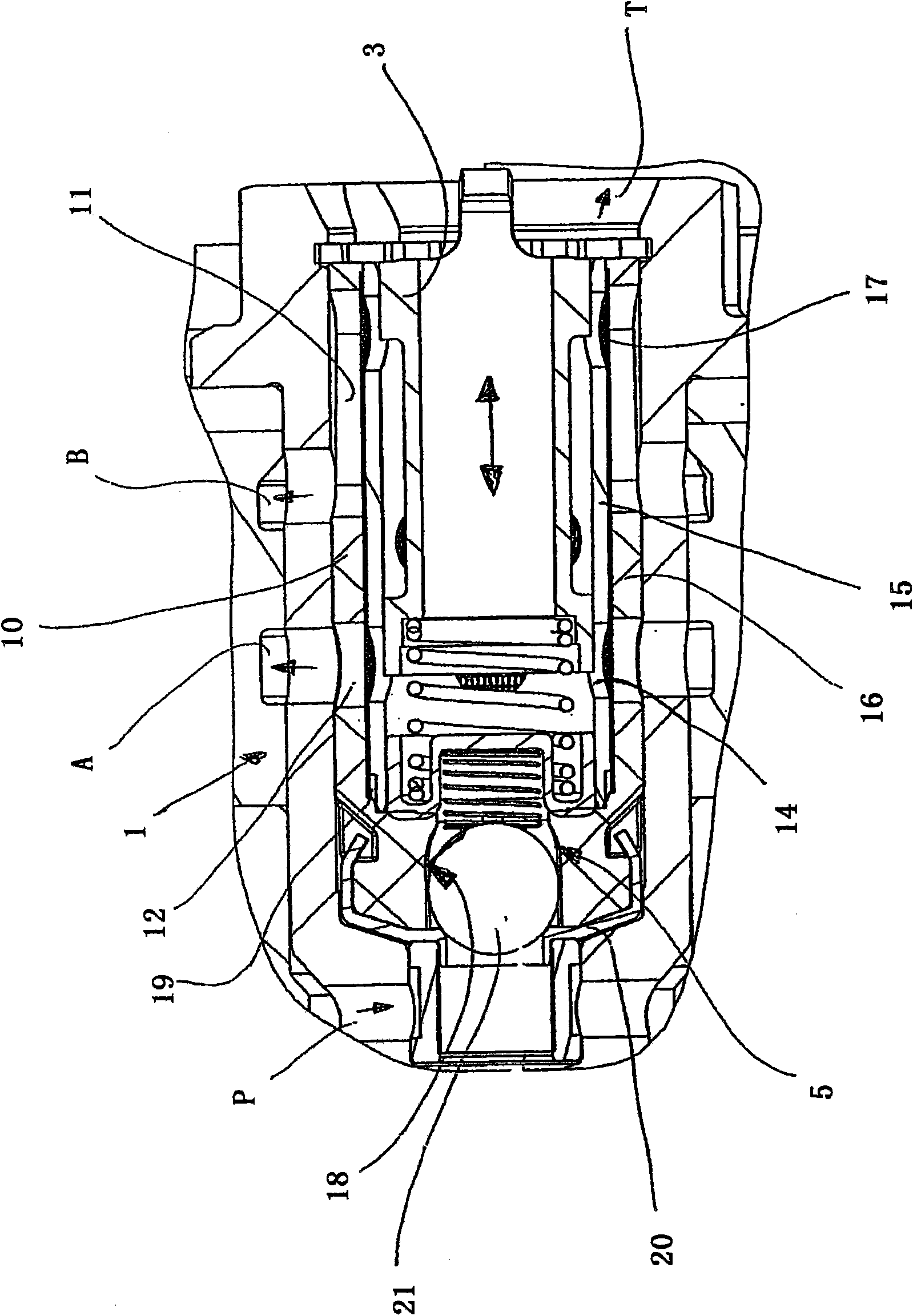

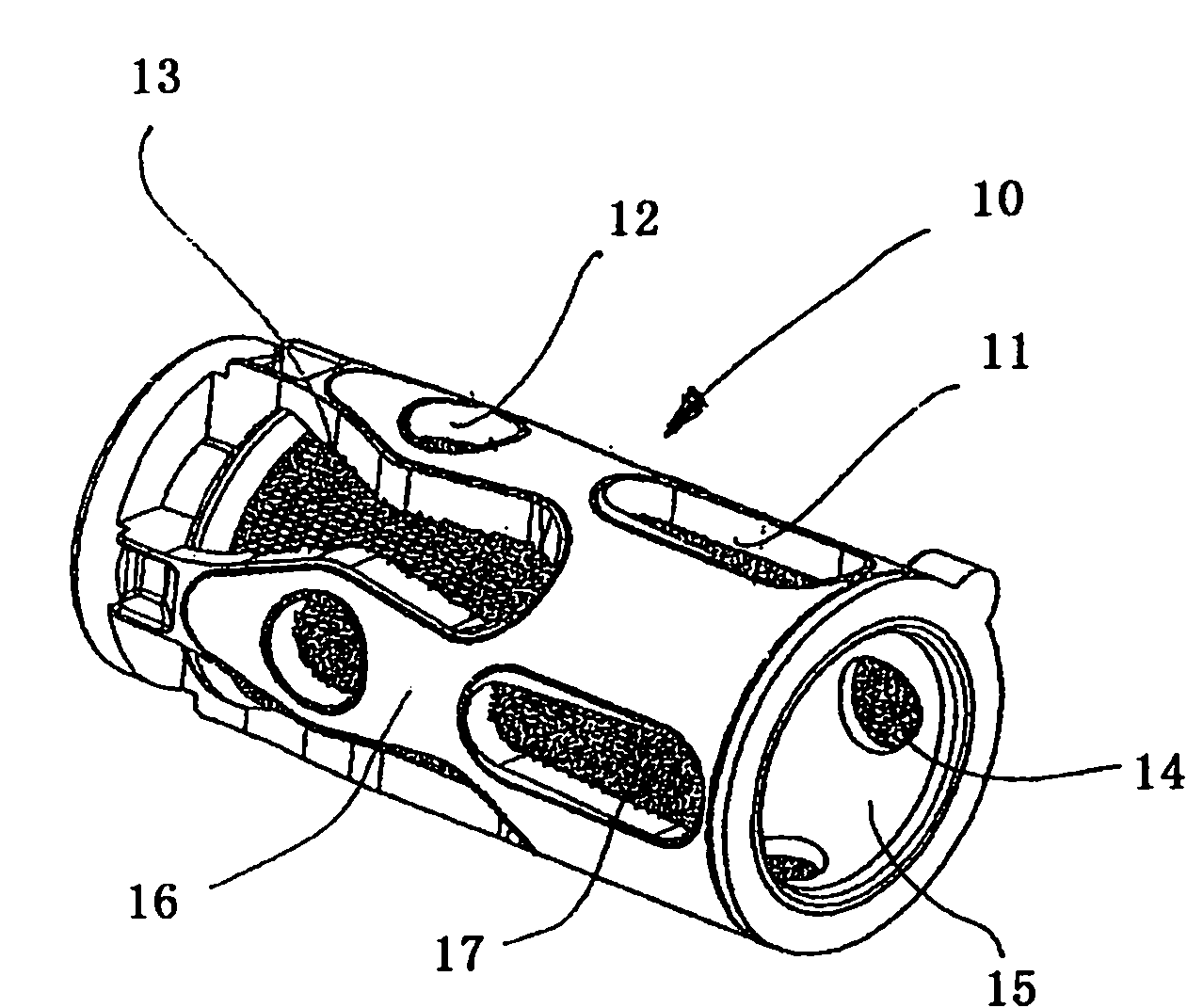

[0020] exist figure 1 A device for variable adjustment of the timing of gas exchange valves of an internal combustion engine is shown in FIG. 2 , which has a transmission wheel 6 which is connected in a rotationally fixed manner to a stator 7 . In addition, a rotor 8 is provided, which is connected in a rotationally fixed manner to the camshaft 4 . The transmission wheel 6 is driven directly or indirectly by the crankshaft of the internal combustion engine. The rotational movement of the drive wheel 6 is then transmitted via the stator 7 to the rotor 8 , so that the camshaft 4 , which is connected in a rotationally fixed manner to the rotor 8 , also rotates. The rotating camshaft 4 then controls the opening and closing times of the gas exchange valves of the internal combustion engine. The adjustment of the control time of the gas exchange valve is then carried out by the relative rotation of the rotor 8 relative to the stator 7 , which is controlled by the control valve 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com