Multi-hearth full-anti-burning coal gasification boiler

A back-firing, coal gasification technology, applied in the field of boilers, can solve problems such as hidden safety hazards, unreasonable structure, substandard flue gas, etc., and achieve the effects of increasing flow rate, fast burning speed, and eliminating fouling and clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

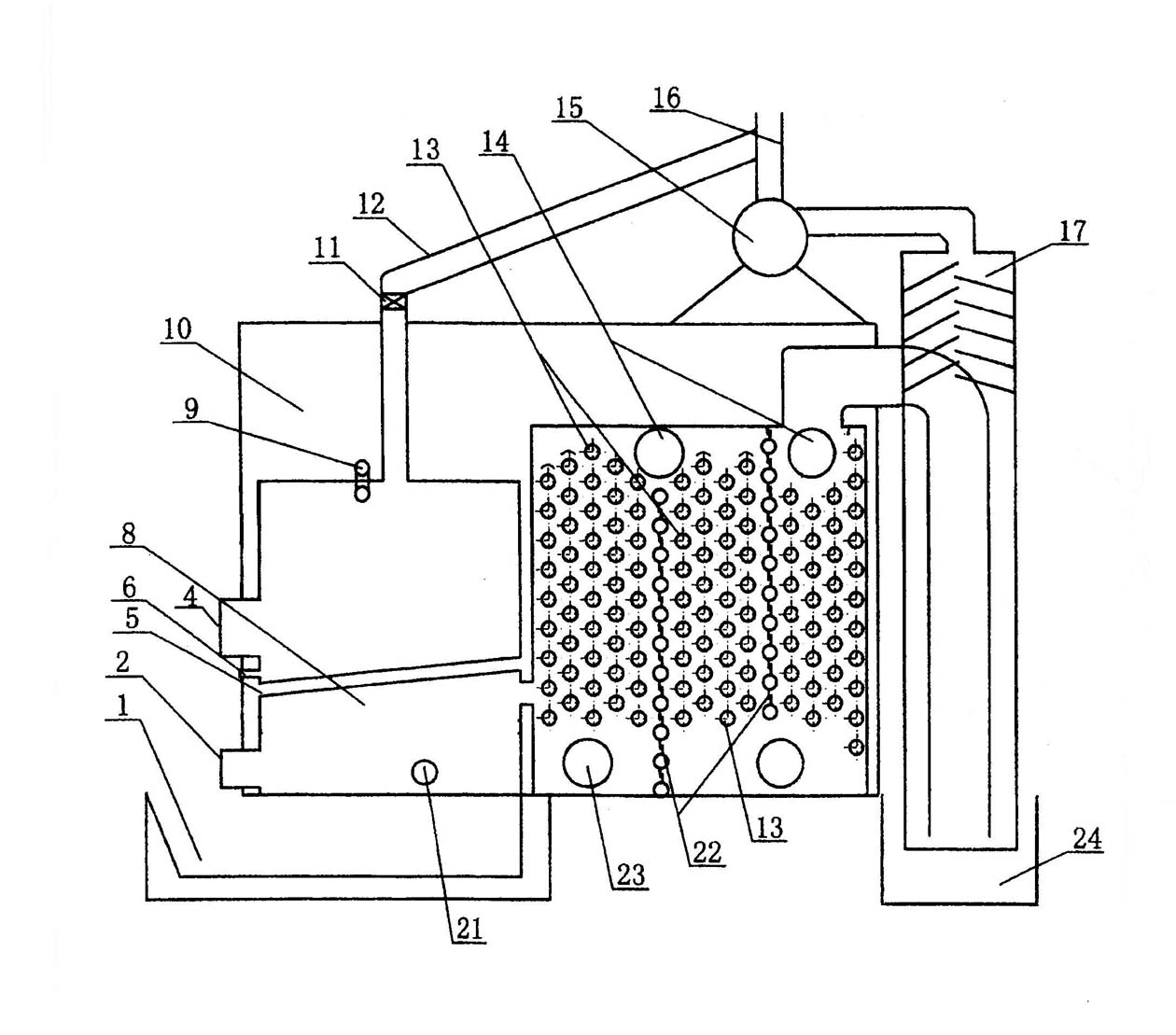

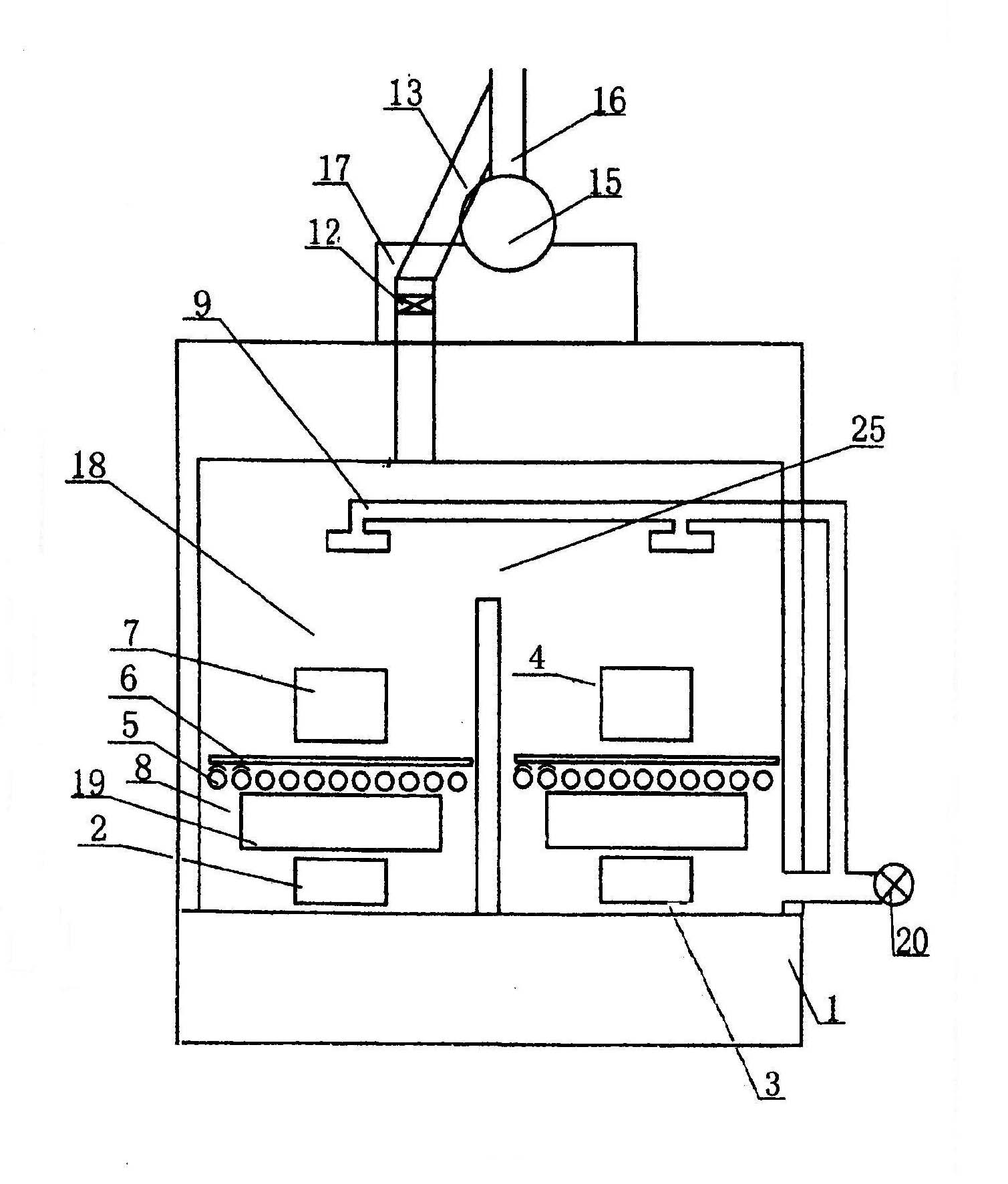

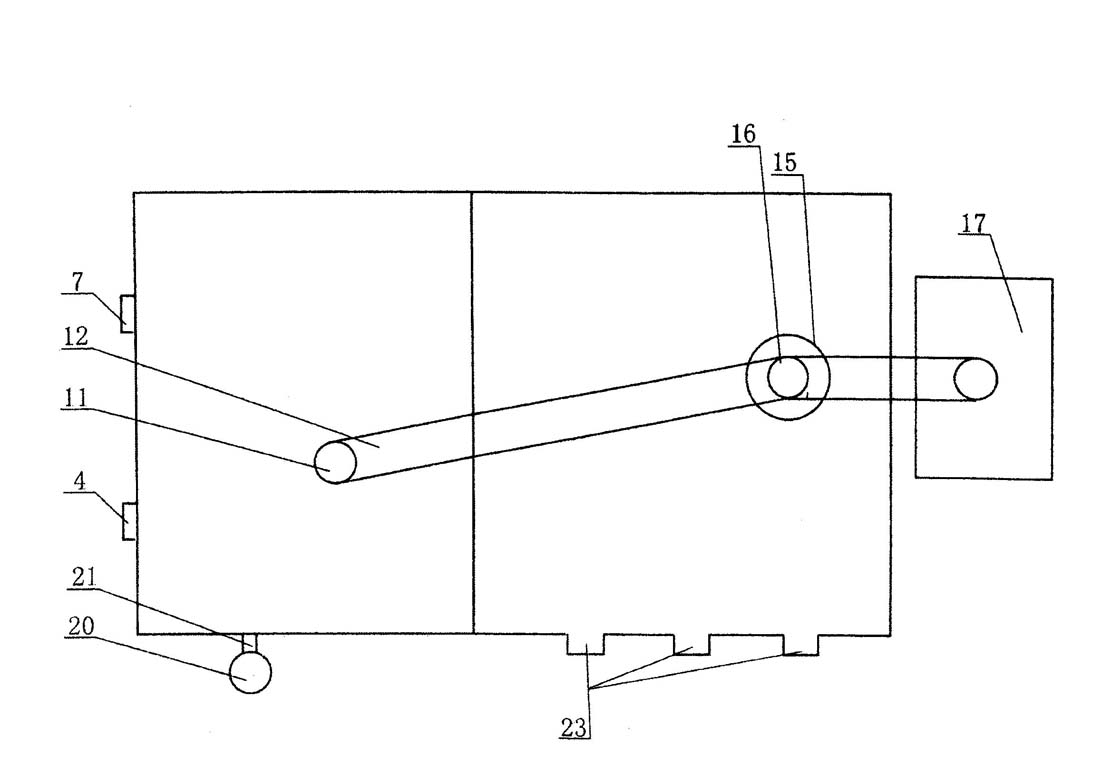

[0022] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0023] Such as figure 1 , 2 As shown in , 3, the multi-furnace full back-burning coal-fired coal gasification boiler includes two back-burning gas generating chambers connected by the back-burning communication port 25 at the upper part and respectively provided with a coaling furnace door 4 and a coaling furnace door 7 18. The lower part of the coal stoker door 4 and the coal stoker door 7 is provided with a counter-burning grate 5 and an ash opening 6 respectively, and the lower part of the ash opening 6 is a combustion chamber 8, a primary high-pressure air 21 and a water-sealed pool 1, the combustion chamber A fire outlet 19 is provided, and a slag outlet 2 and a slag outlet 3 are provided at the lower part of the fire outlet 19. A secondary high-pressure air 9 is provided above the reverse combustion gas generating chamber 18, and a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com