Power drive system of power converting machinery

A technology of transmission system and mechanical power, which is applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of blocked start, uncertain motion, and not suitable for mining machinery, etc., and achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

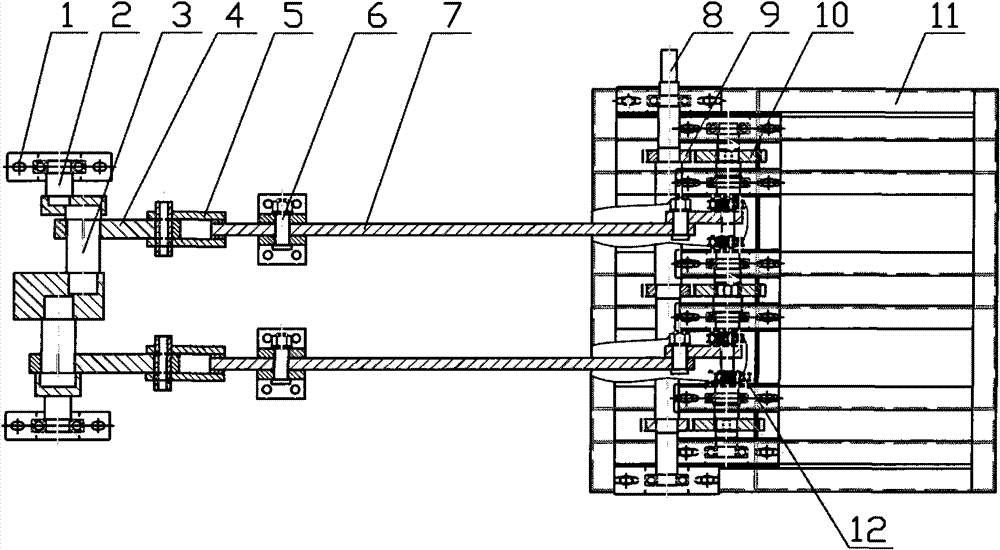

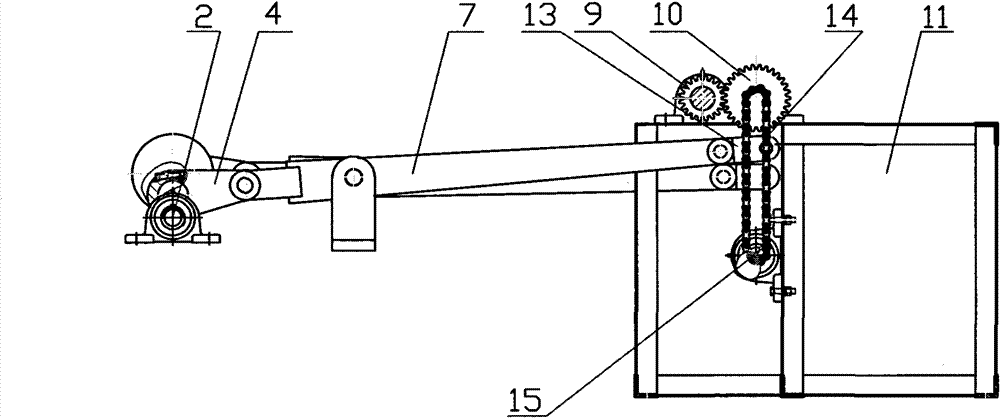

[0027] Refer to the attached figure 1 A power conversion mechanical drivetrain is shown, which includes:

[0028] The crankshaft 2 is the power output part of the transmission system. The crankshaft is provided with two connecting rod journals 3, and the angle between the crank arms of the two connecting rod journals is greater than 15° and less than or equal to 90°;

[0029] A crank connecting rod 4, one is provided corresponding to each connecting rod neck;

[0030] The main shaft 8 is used as the power input part of the transmission system; and

[0031] The transmission parts are two sets with the same constant transmission ratio, which are correspondingly connected between the crank connecting rod and the main shaft, and are used for driving the corresponding crank connecting rod.

[0032] Regarding the crankshaft, such as figure 1 As shown, to configure the bearing housing 1, according to the inventive idea of introducing multiple pins in the present invention, it se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com