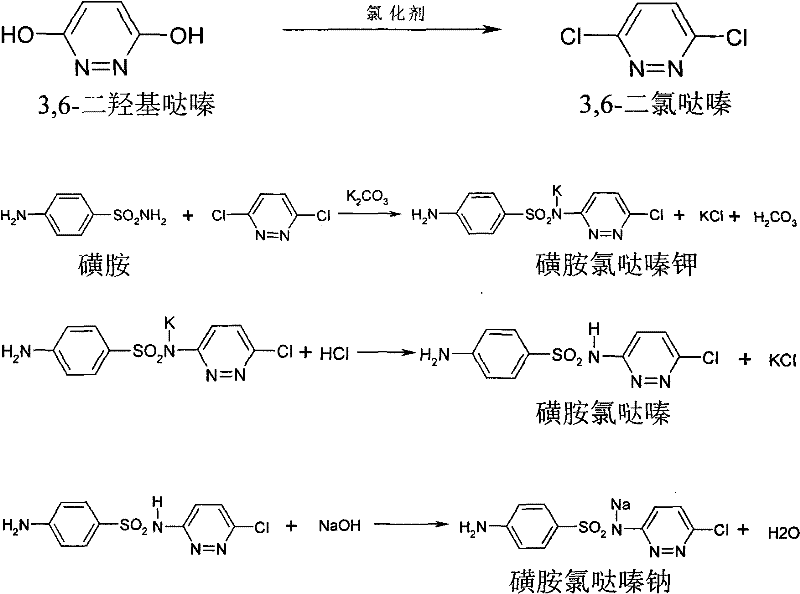

Method for preparing sulfachlororyridazine sodium

A technology of sulfachloropyridazine sodium and dichloropyridazine, which is applied in the field of preparation of sulfonamide antibacterial agent-sulfachloropyridazine sodium, to achieve the effects of cost reduction, good practical value, and simplified production and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is illustrated by the following examples, but the present invention is not limited to the following examples. Without departing from the purpose described before and after, all changes and implementations are included in the technical scope of the present invention.

[0019] Steps:

[0020] 1. Preparation of 3,6-dichloropyridazine:

[0021] Add 40 grams (0.36 moles) of 3,6-dihydroxypyridazine and 164 grams (1.20 moles) of phosphorus trichloride (or other chlorination agents such as thionyl chloride or chlorine with equimolar) in the there-necked flask, Heat to 65-70°C, stop heating, and raise the temperature naturally. After the reaction climax occurs, keep the reaction at 80-100°C for 3-5 hours, and recover phosphorus trichloride (or thionyl chloride, or chlorine gas) under reduced pressure. Then, use 300 grams of o-dichlorobenzene (or at least any one of chlorobenzene, p-dichlorobenzene, ortho-dichlorobenzene, toluene, trichloroethylene, dichlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com