Towing vehicle for transporting supports

The technology of a trailer and a frame is applied in the field of auxiliary transportation equipment in coal mines, and can solve the problems of difficult handling, heavy support, frequent handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

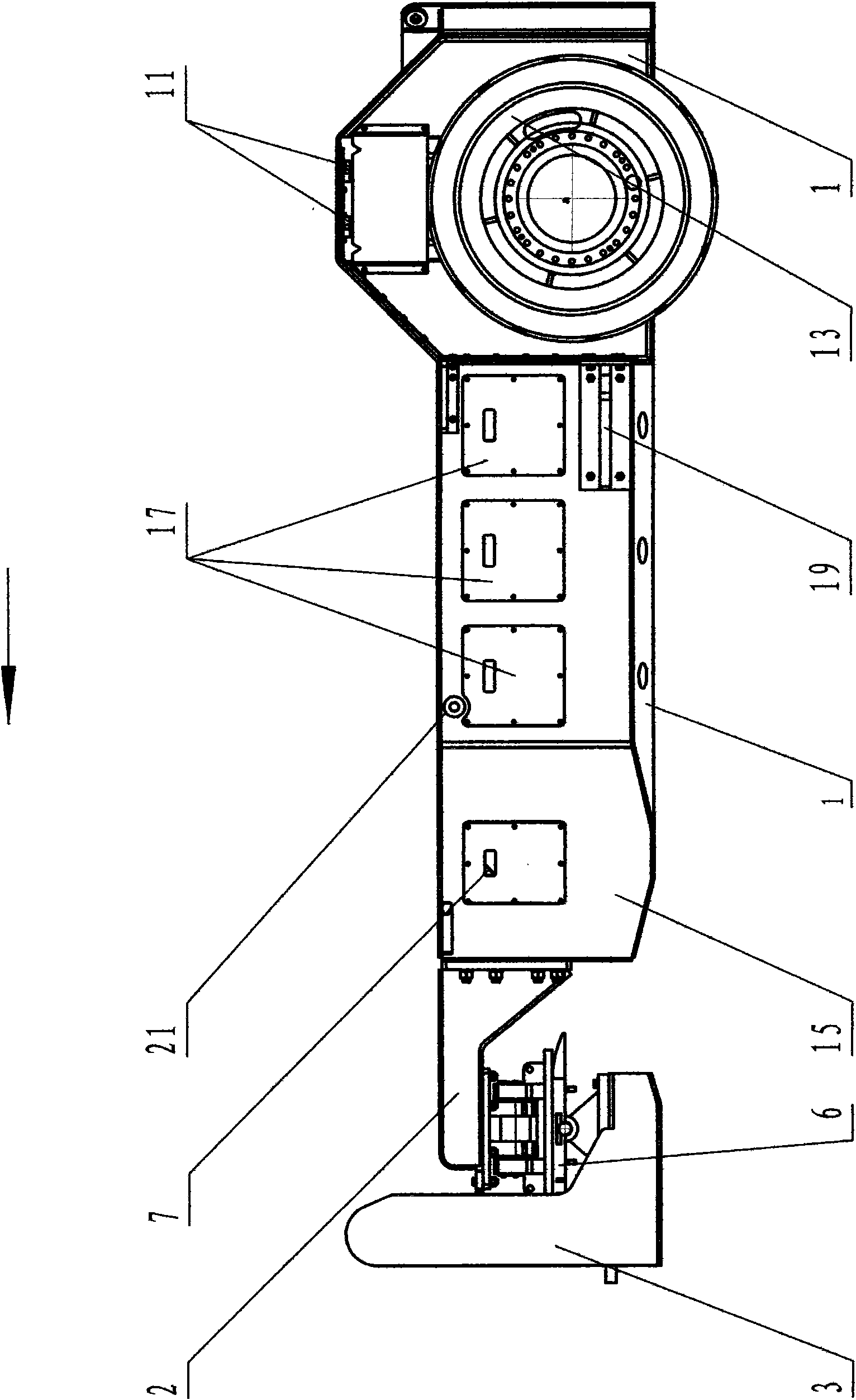

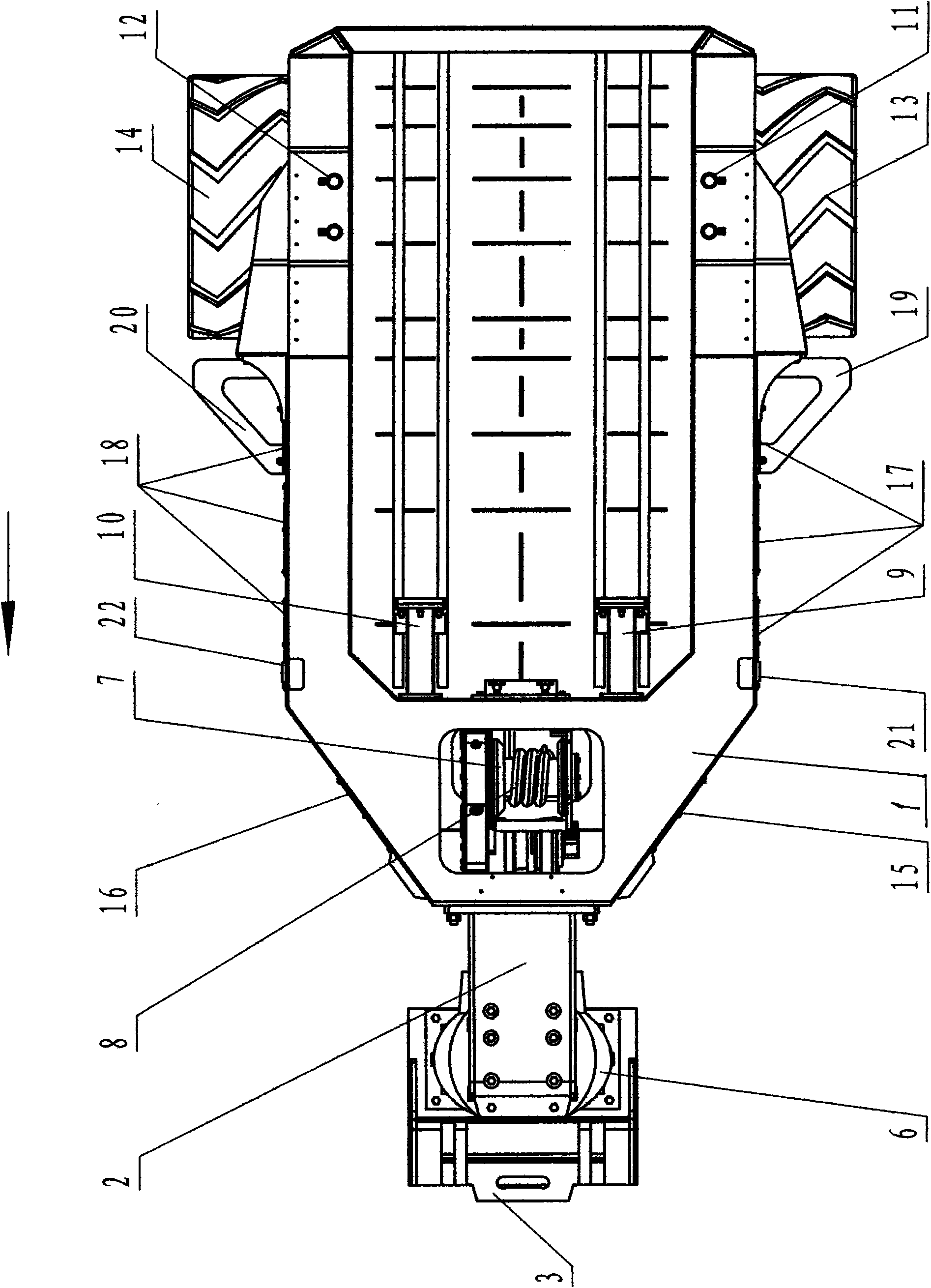

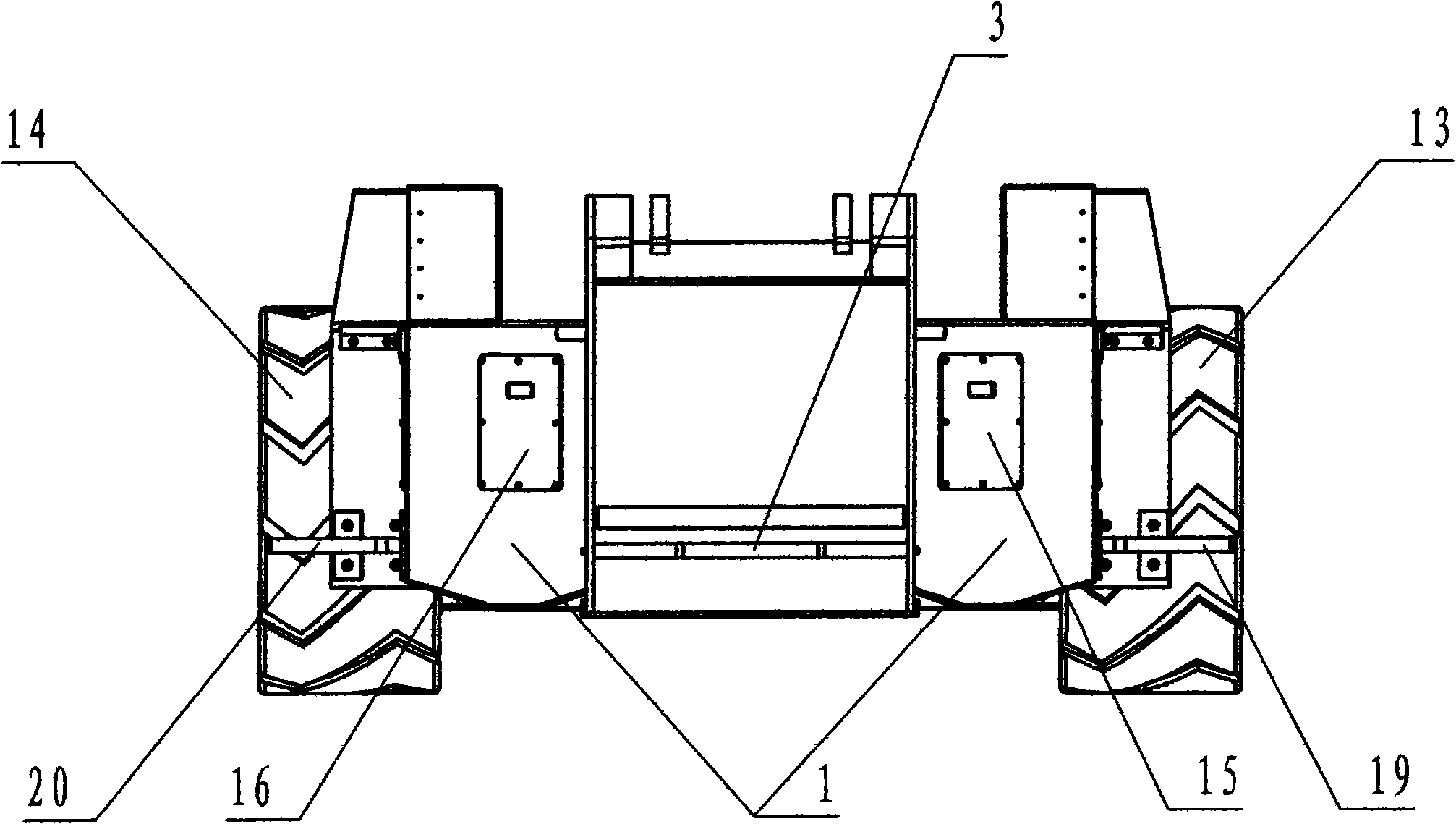

[0018] figure 1 , 2 . As shown in 3, it is the overall structure diagram. The position and connection relationship of each part must be correct and the installation should be firm.

[0019] The U-shaped vehicle frame 1 is a U-shaped trough-shaped box body, the front part of the U-shaped vehicle frame 1 is a traction plate 2, and the front part of the traction plate 2 is a connecting plate 3; the lower part of the traction plate 2 is equipped with a traction seat 6; the U-shaped vehicle frame 1. The middle position of the front part is a winch 7, and a cable 8 is installed on the winch 7; the first push cylinder 9 and the second push cylinder 10 are arranged on the left and right in the front part of the U-shaped vehicle frame 1; Wheels 13, second wheels 14; a first lifting cylinder 11 and a second lifting cylinder 12 are arranged on the left and right sides of the rear pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com