Steel for welding structure having welded joint with superior ctod properties in weld heat affected zone

A welding joint and welding structure technology, applied in the field of welded structural steel, can solve the problems of not controlling the fine structure and grain size of the welding metal, not controlling the oxygen or nitrogen content of the welding metal, and difficult to ensure the impact toughness of the welded joint, etc. The effect of excellent strength and CTOD properties, excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

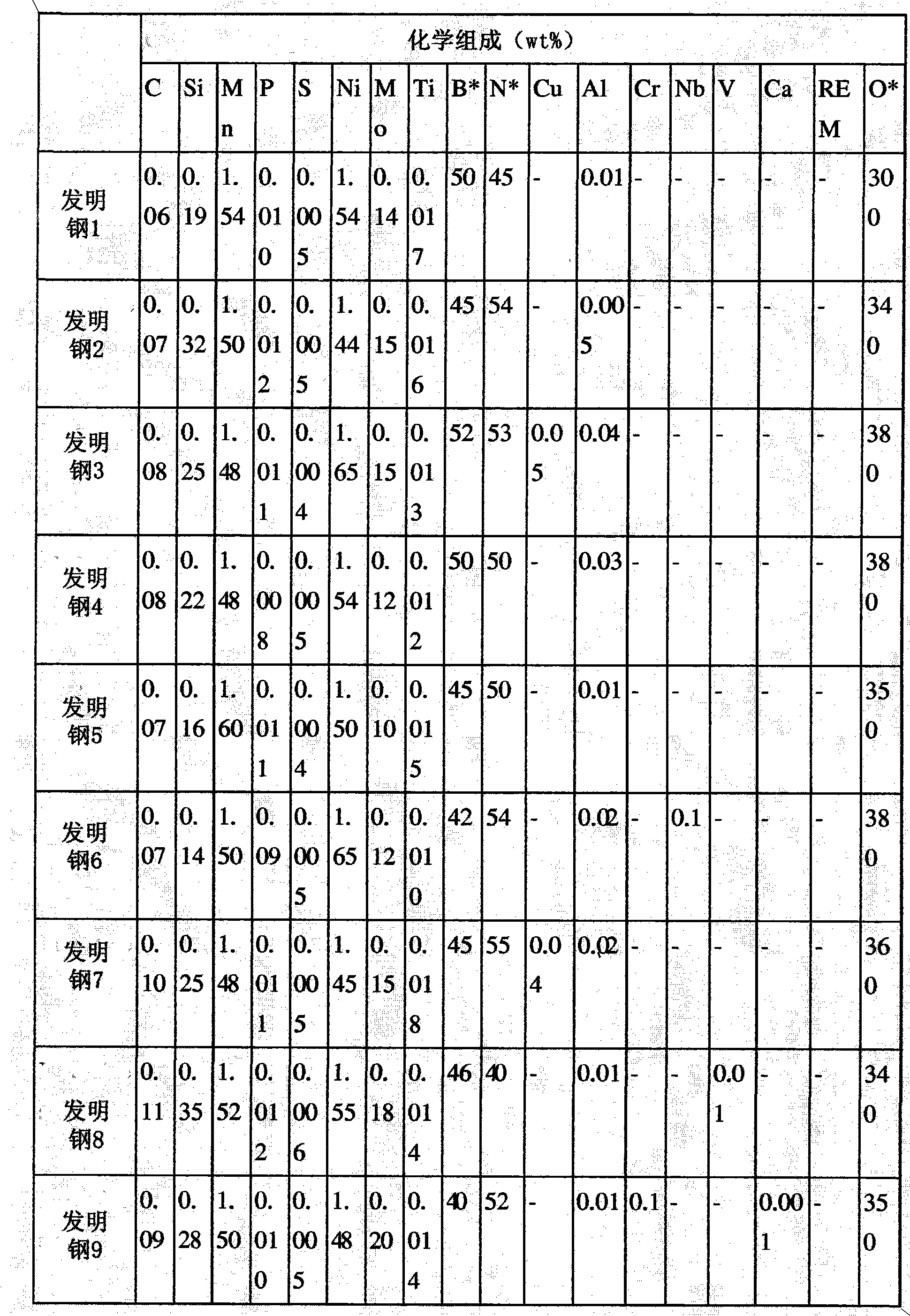

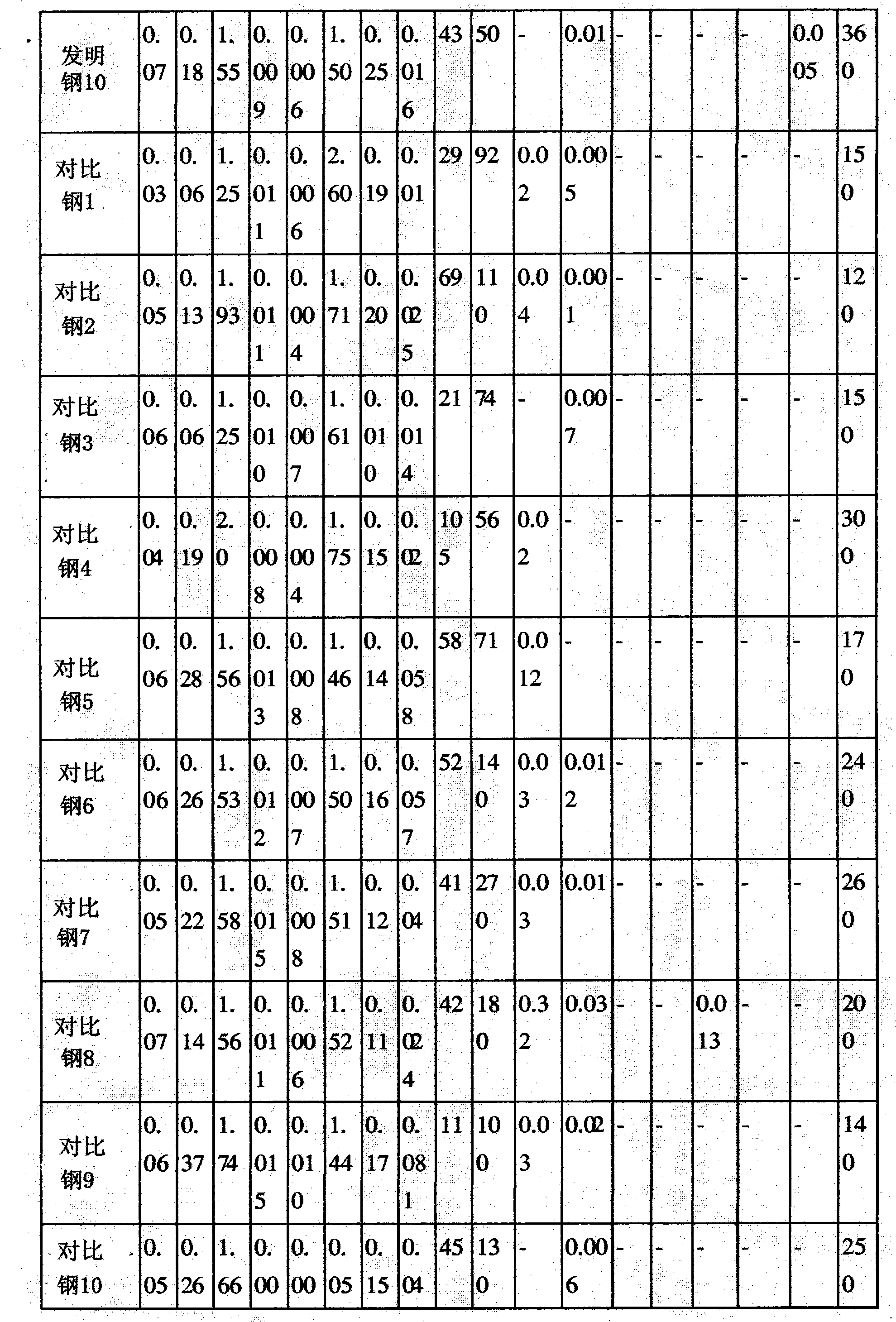

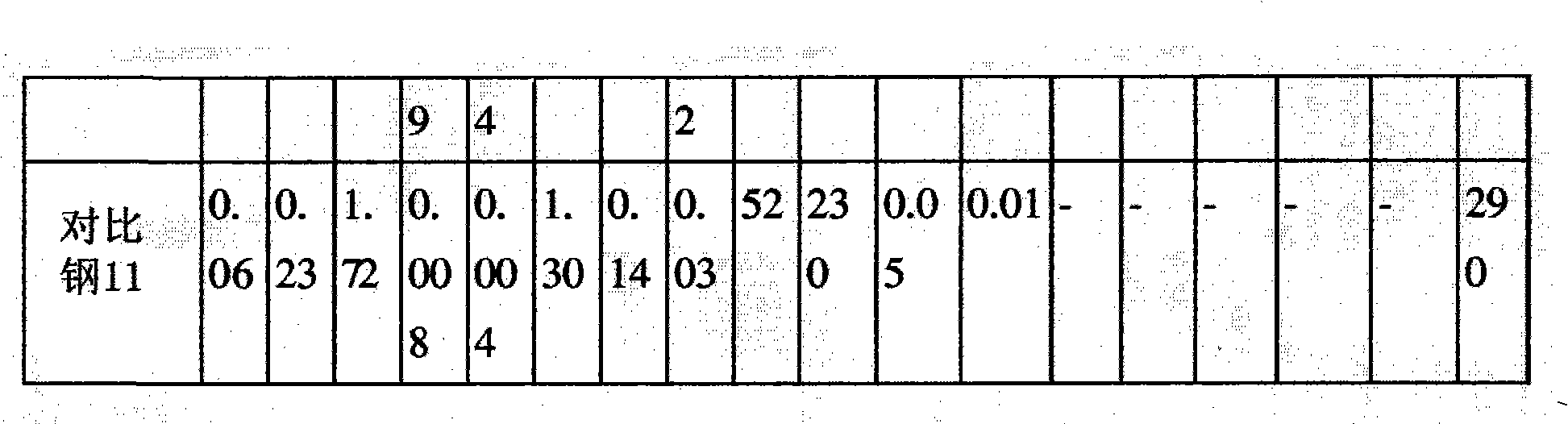

[0083]Certain / exemplary aspects of the invention are now described in detail by the following examples and tables.

[0084] A weld metal zone having the elemental composition shown in Table 1 below was fabricated by the SAW method with a heat input of 30-45 kJ / cm or higher. Table 2 shows the ratios of alloying elements in the weld metal zone that exhibit the effects of the present invention.

[0085] Samples for evaluating the mechanical properties of the weld metal zone were taken from the middle portion of the weld metal zone welded in the aforementioned manner. A sample of KS Standard No. 4 (KS B 0801) was used as a sample for the tensile test. The tensile test was performed at a slide speed of 100 mm / min. CTOD specimens are manufactured based on BS7448-1 standard, and a fatigue crack is set in the center of the SAW weld metal zone.

[0086] Measure the size, amount and spacing of oxides that significantly affect the toughness of welded metal parts by spot counting using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com