Parallel-connection three-dimensional force sensor with decoupling structure

A three-dimensional force and sensor technology, applied in the field of sensors, can solve the problems of complex design, calculation and manufacturing, low precision, and difficult coupling between various forces, and achieve the effect of simple structure, convenient processing, and clear working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

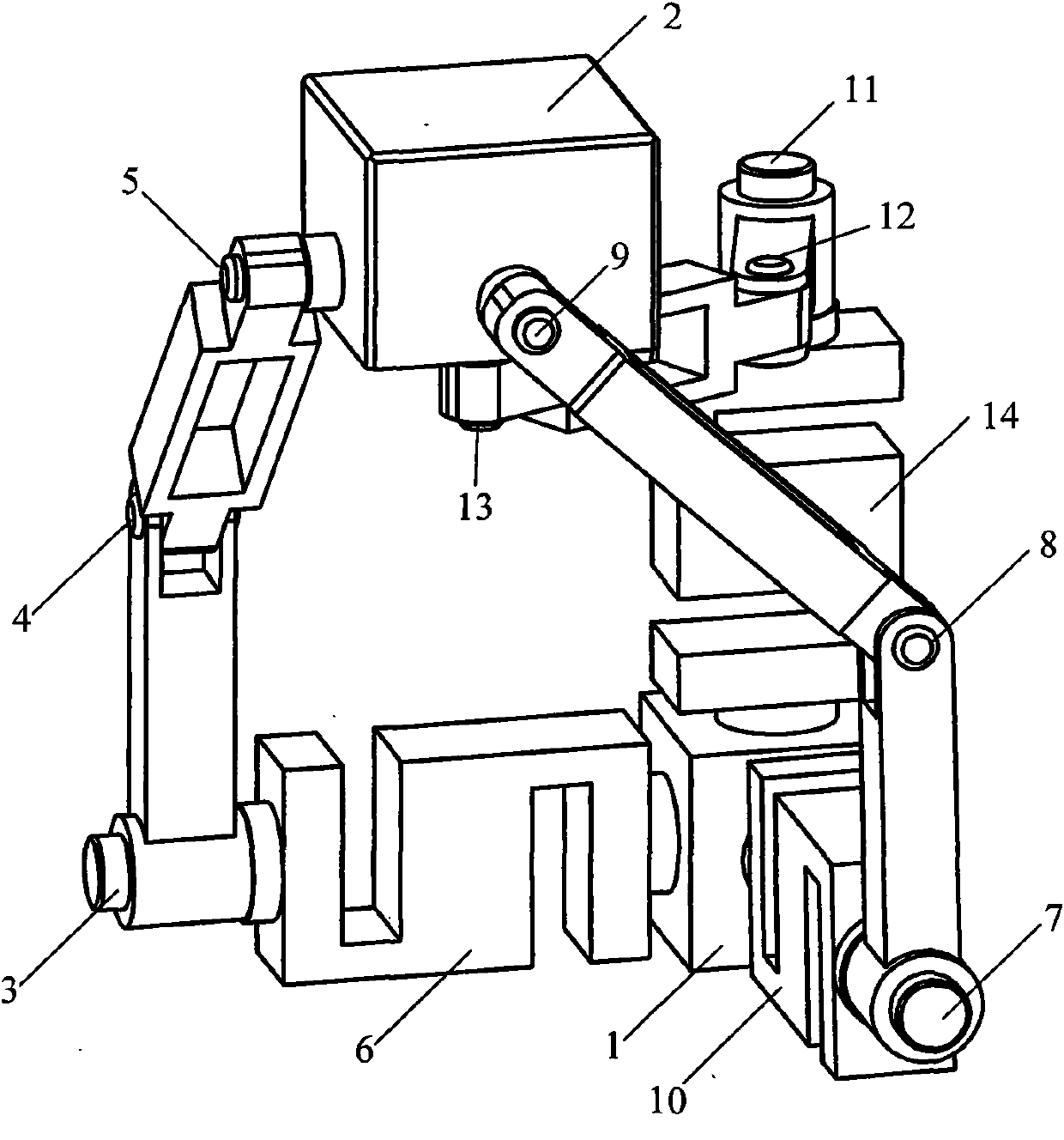

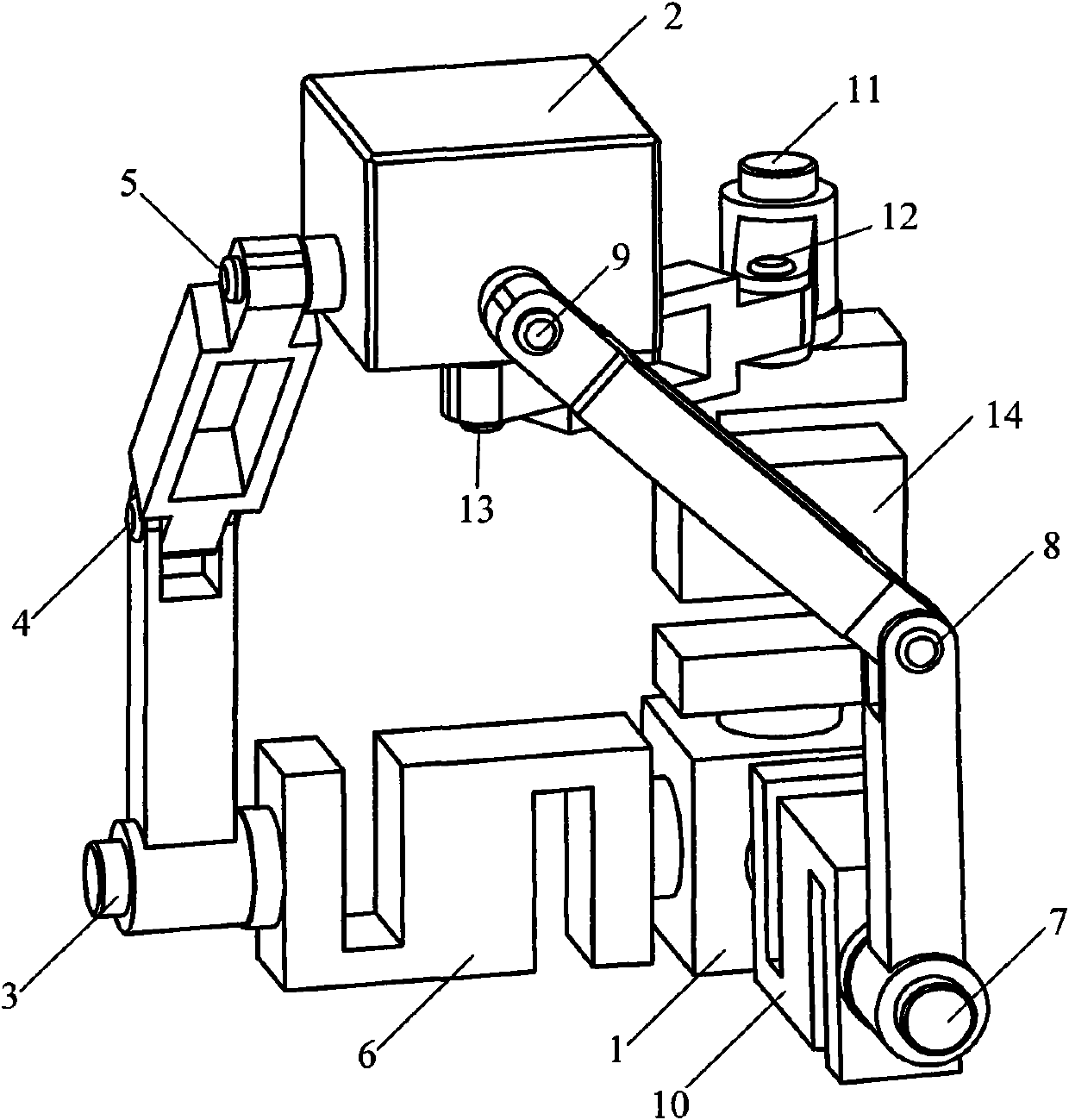

[0014] Parallel decoupling structure three-dimensional force sensor (see figure 1 ), consisting of a fixed base 1, a force measuring platform 2 and three branches, branch 1, branch 2 and branch 3 are composed of rotating pairs 3, 4, 5, rotating pairs 7, 8, 9, and rotating pairs 11, 12 , 13; the fixed base 1 is fixedly connected with the force-sensitive sensing elements 6, 10, 14, and the fixed base 1 and each force-sensitive sensing element 6, 10, 14 and the three branches are respectively connected by rotating pairs 3, 7, 11 The force-measuring platform 2 is connected with the three branches through the rotating pairs 5, 9, and 13 respectively. The axes of the three rotating pairs forming each branch are parallel to each other, and the axes of the rotating pairs between different branches are perpendicular to each other; The force signals detected by the force-sensitive sensing elements 6, 10, and 14 fixedly connected to the fixed base 1 are consistent with the axis direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com