Trenchless repairing method of underground pipeline with drawing-type liner pipe

An underground pipeline and repair method technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of uneven heat transfer of hot water, uneven curing strength of resin hoses, etc., to protect the environment, Accelerate the curing reaction speed, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

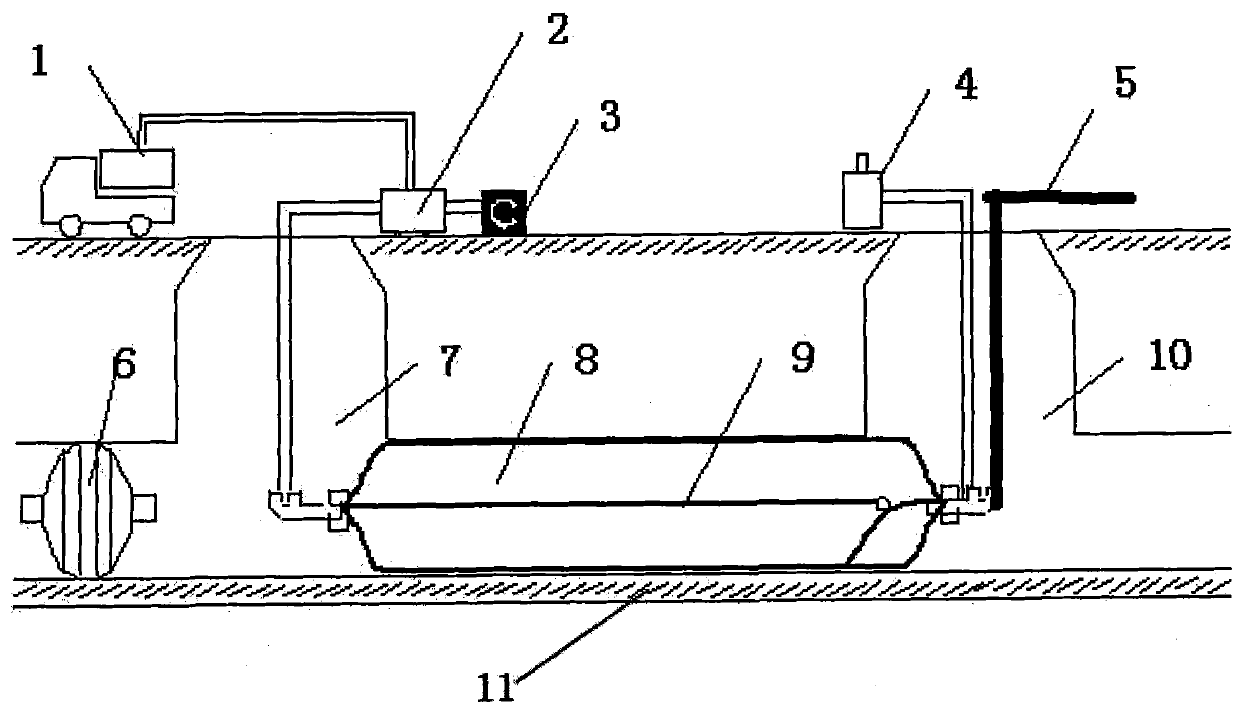

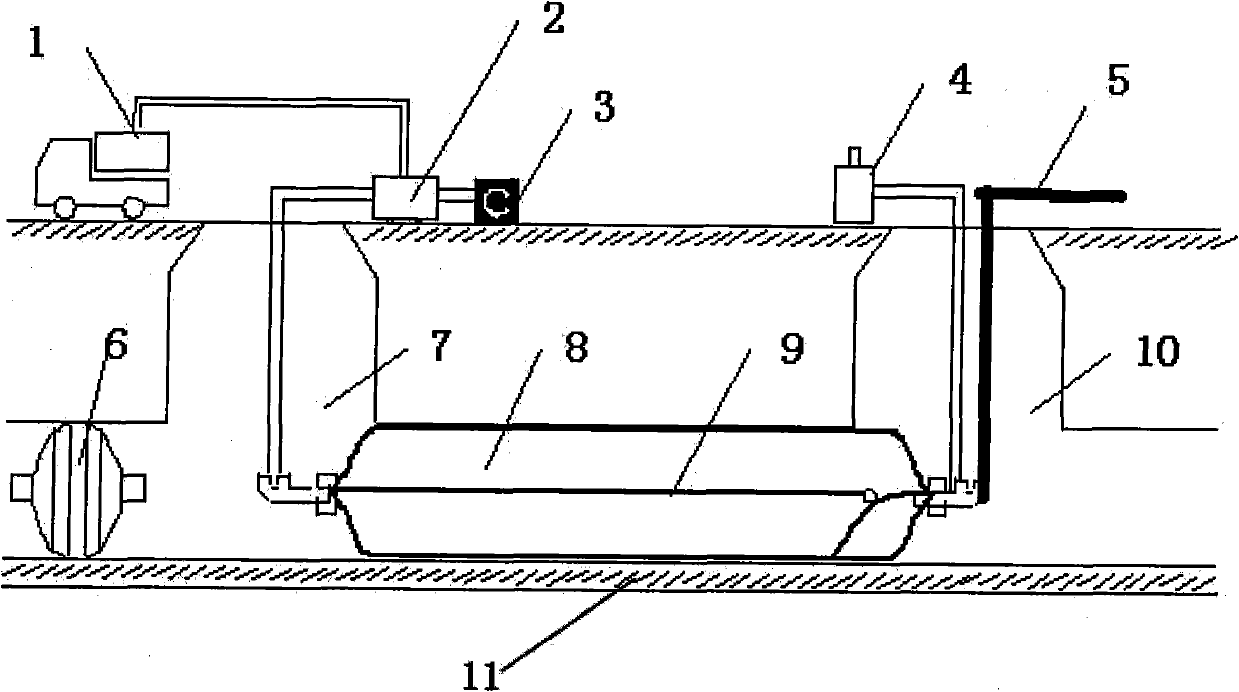

[0049] Before the impermeable cylindrical auxiliary lining hose is sent into the old pipeline to be repaired, the thermosetting resin is pre-impregnated in the non-woven hose to form a resin hose, and the inside and outside are turned over. Then,

[0050] Block and clean the old sewage pipelines that need to be repaired, and use closed-circuit television system CCTV equipment to detect the inside of the pipelines. The pipeline is fed into the impermeable cylindrical auxiliary lining hose, which is lined on the inner wall of the pipeline to be repaired.

[0051] The resin hose that has been turned inside and outside beforehand is pulled together with the hot water delivery pipe for heating into the impermeable cylindrical auxiliary lining hose in a deflated state.

[0052] After the inside and outside of the resin hose are turned over, the pulling operation of sending the resin hose together with the hot water delivery pipe for heating into the water-tight cylindrical auxiliar...

Embodiment 2

[0061] Except for the following differences, it is the same as Embodiment 1, implementing the lining pipe pulling type underground pipeline trenchless repair method of the present invention.

[0062] 0.8kgf / cm2 air pressure is used to make the lining pipe expand and stick to the inner wall of the old pipe. Then, the inside of the resin hose is heated with 85-degree hot water circulation, so that the thermosetting resin hose is gradually hardened and formed.

[0063] The diameter of the pipeline to be repaired in this embodiment is Φ300-Φ600mm.

Embodiment 3

[0065] Except for the following differences, it is the same as Embodiment 1, implementing the lining pipe pulling type underground pipeline trenchless repair method of the present invention.

[0066] 0.8kgf / cm2 air pressure is used to make the lining pipe expand and stick to the inner wall of the old pipe. Then, the inside of the resin hose is heated with 85-degree hot water circulation, so that the thermosetting resin hose is gradually hardened and formed.

[0067] The diameter of the pipeline to be repaired in this embodiment is Φ500-Φ800 mm.

[0068] According to the non-excavation repair method of lined pipe pulling type underground pipeline of the present invention, the resin hose and the hot water delivery pipe for heating that have been made and turned over in the factory in advance are pulled into the old pipe that has been placed inside the old pipe. The water-permeable cylindrical auxiliary lining hose, and then, the above-mentioned resin hose pulled in is expanded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com