Non-light tight concrete member and manufacturing method thereof

A technology of light-transmitting concrete and manufacturing process, applied in building components, building structures, walls, etc., can solve the problems of no light-transmitting, ordinary concrete walls cannot meet functional requirements, etc., and achieve simple equipment technology and reduce heat exchange. Loss, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

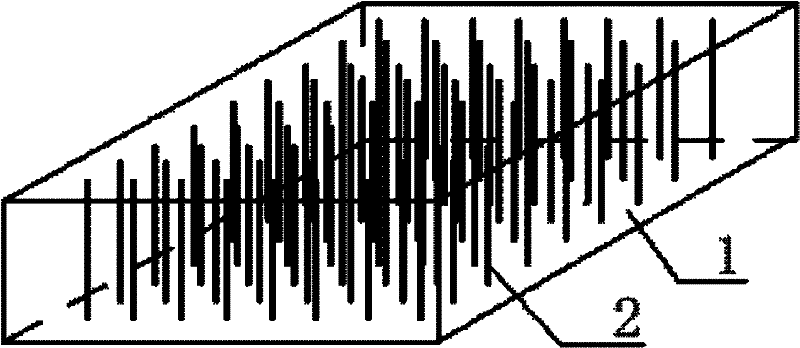

[0017] see figure 1 , the product of this embodiment includes a concrete main body 1, in which uniformly arranged optical fibers 2 are fixed, and the optical fibers 2 pass through the upper and lower sides of the concrete main body 1 shown in the figure.

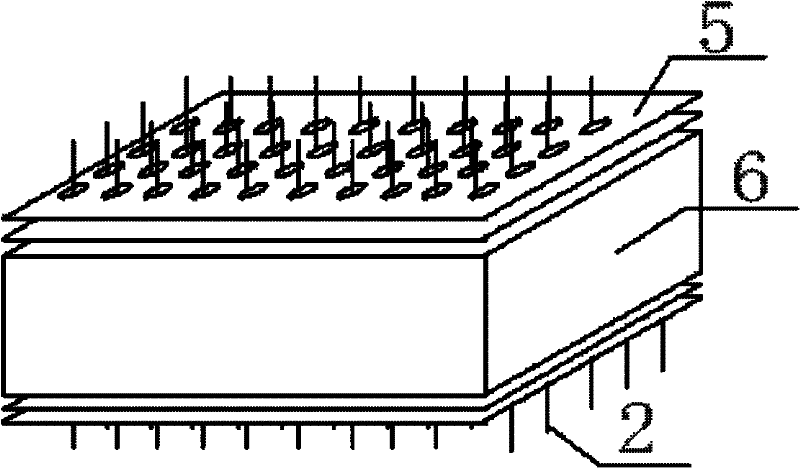

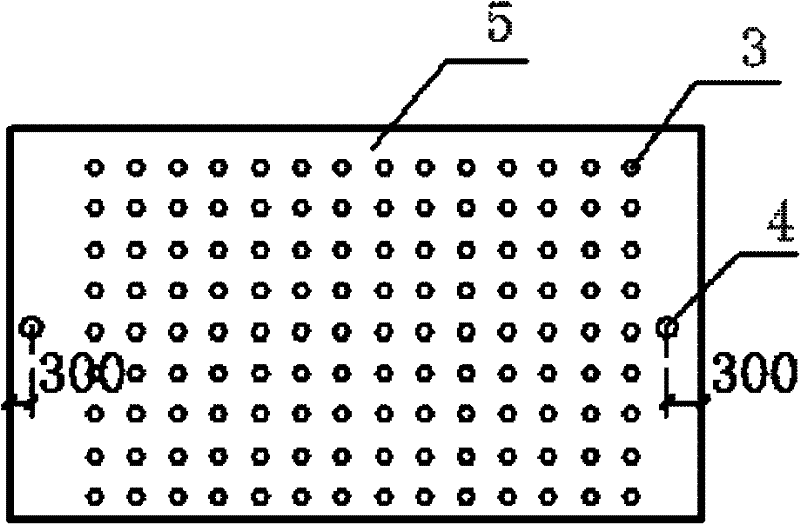

[0018] The technological process of manufacturing present embodiment product is as follows: see figure 2 , at first, make the outer formwork 6 of component according to the size of required concrete member, generally adopt wooden formwork or steel formwork, make the optical fiber fixed formwork 5 that is slightly bigger than the area of upper and lower two sides of outer formwork 6 again. see image 3 and Figure 4 1. On the optical fiber fixing template 5, drill the optical fiber round hole 3 with the same number and position as the optical fiber and whose diameter is 1.5 mm larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com