Method for controlling membrane pollution in membrane bioreactor

A technology of membrane bioreactor and bioreactor, which is applied in the fields of chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc., can solve the obstacles to the promotion and application of membrane reactors, the increase of membrane pressure, and the inconvenience of operation and management To achieve the effects of slowing down and controlling membrane fouling, increasing membrane filtration performance, and high effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

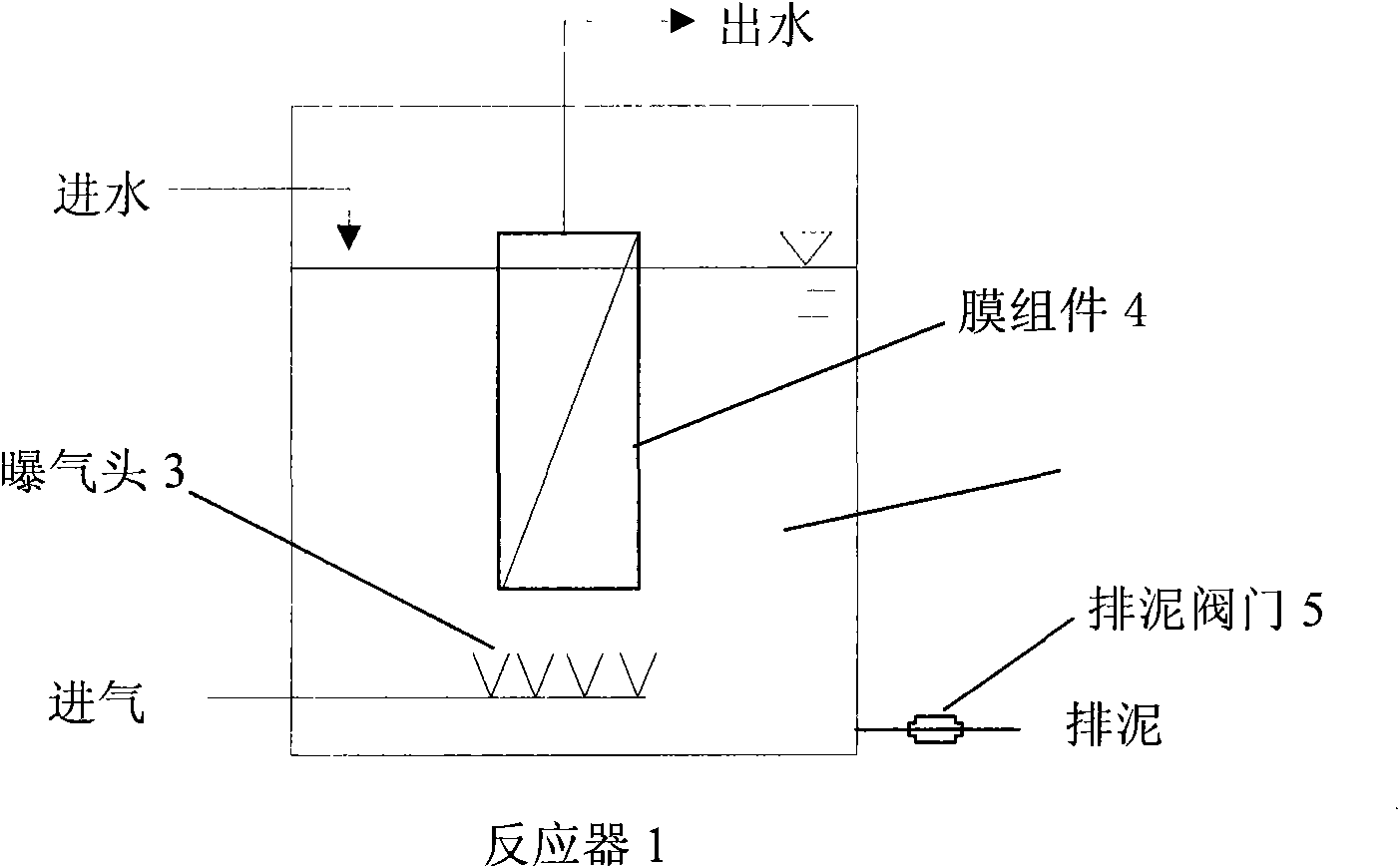

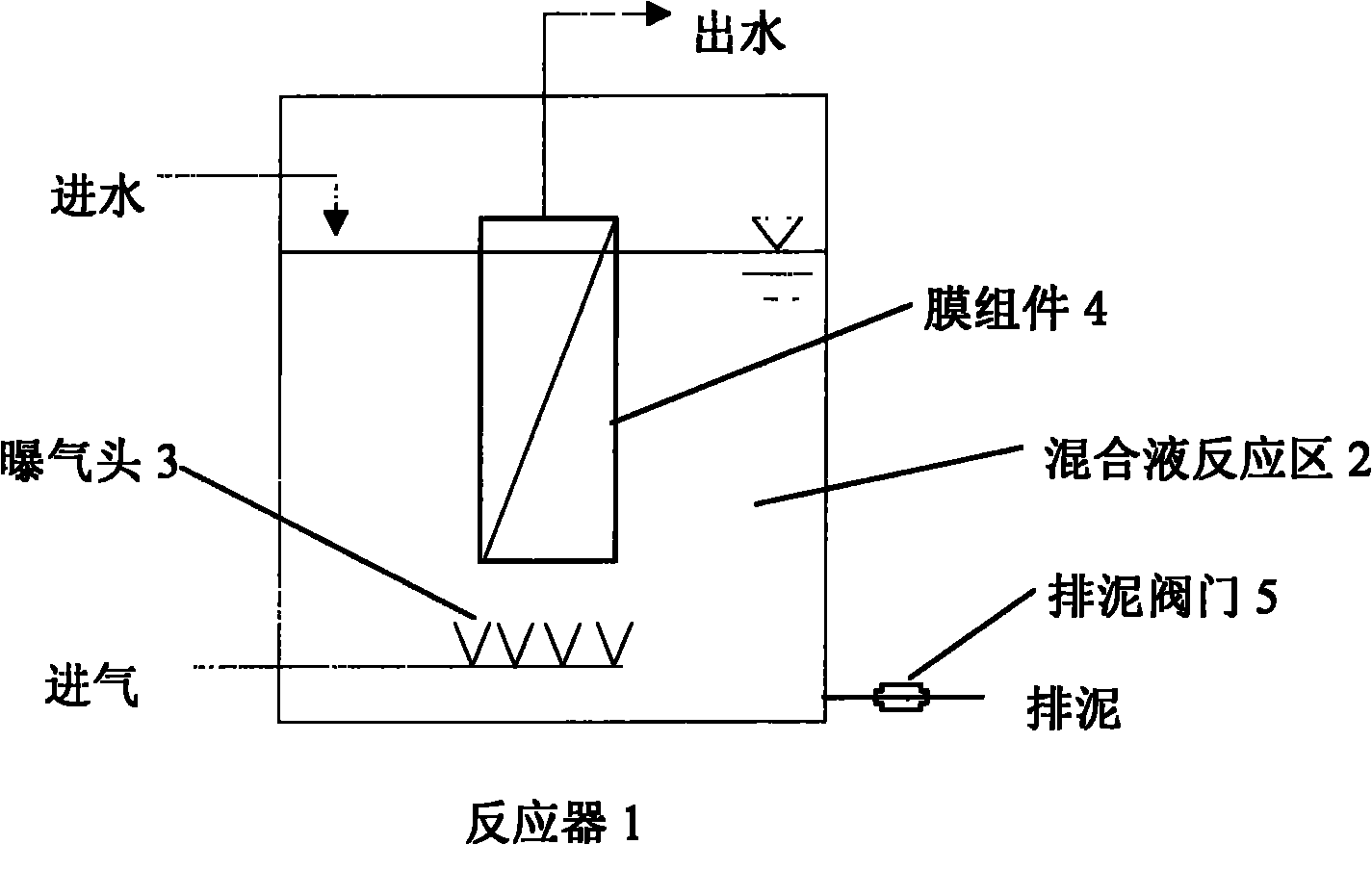

Image

Examples

Embodiment 1

[0018] Make ferric sulfate into an aqueous solution, then add sodium carbonate (Na 2 CO 3 ) into a polyferric sulfate solution, take 500ml of the sludge mixture in the reactor to a beaker, and carry out a short-term intermittent experiment. Add flocculant during rapid stirring, first stir quickly for 2min (200rpm), then stir slowly for 15min (60rpm) until the coagulation reaction is complete, and determine the optimal dosage is 0.8mM by comparing the specific resistance of sludge.

[0019] Add 1L of the prepared 28mM polyferric sulfate solution into the reactor to treat the mixed liquid solution. The effective volume of the reactor is 35L, so that the concentration of the flocculant in the reactor reaches the optimal dosage of 0.8mM, and the sludge is discharged every day , After the above treatment, the filterability of the mixed liquid membrane is enhanced, and the sludge concentration is reduced, which can achieve the purpose of slowing down and controlling membrane foulin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com