Bamboo fiber rolling machine

A technology of bamboo fiber and rolling machine, which is applied in the direction of wood processing utensils, manufacturing tools, etc., can solve the problems of low production efficiency and high labor intensity, and achieve the effect of high production efficiency, low labor intensity and lightening labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

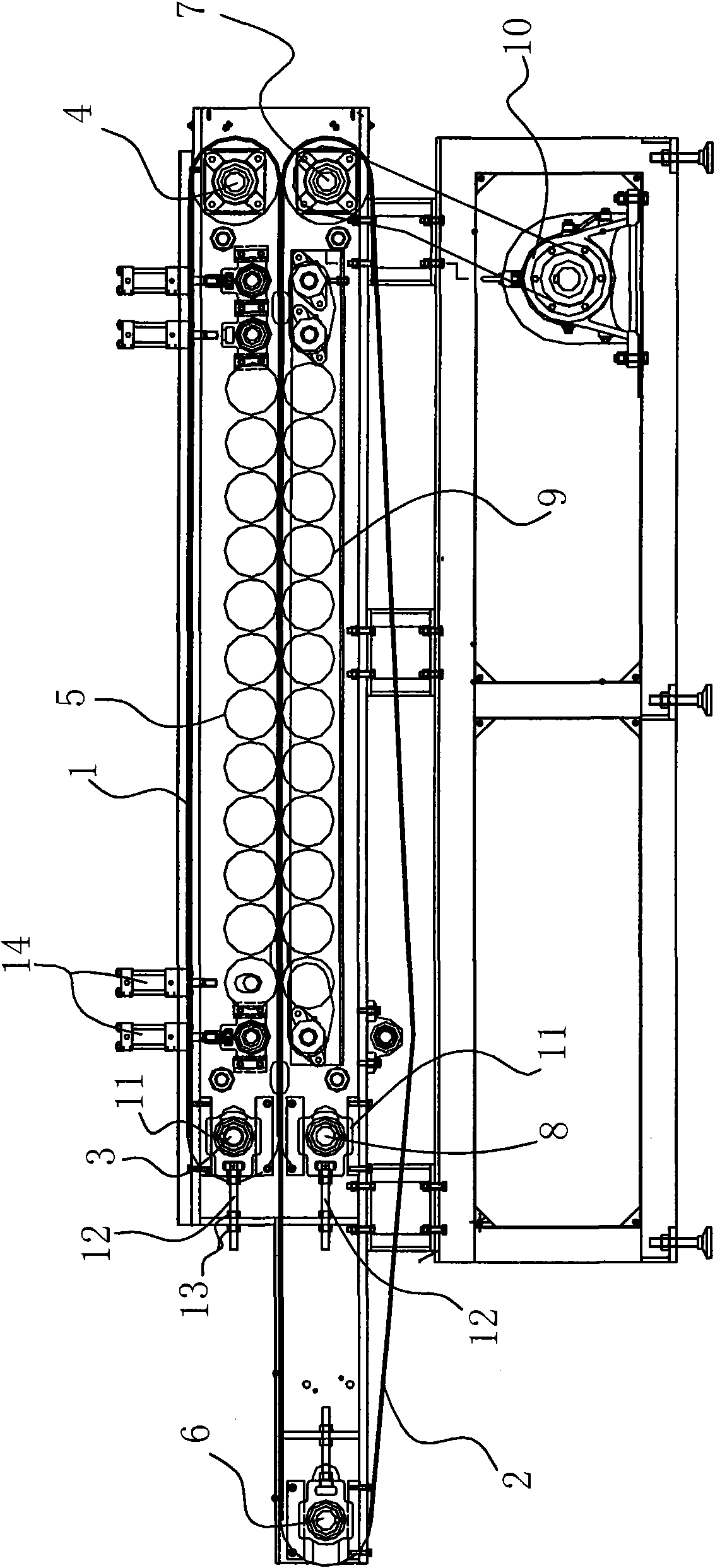

[0017] combine Figure 1 to Figure 3 , a bamboo fiber rolling machine, comprising an upper annular belt 1 and a lower annular belt 2, wherein the lower annular belt 2 is longer than the upper annular belt, and the upper belt body corresponding to the long section of the lower annular belt 2 The belt surface forms a raw material feeding area 201, and a raw material clamping and conveying area is formed between the upper annular belt and the lower annular belt opposite parts. The front end of the upper endless belt is provided with a front upper main roller 3, the rear end of the belt is provided with a rear upper main roller 4, and a plurality of upper pressure rollers 5 arranged in a line are arranged in the belt of the upper endless belt. The upper press roll 5 is located between the front upper main roll 3 and the rear upper main roll 4 . The in-band front end of the endless belt 2 below is provided with the first lower main roller 6, the rear end in the belt is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com