Magnetic concentrator structure for magnetic pulse formation

A technology of magnetic pulse forming and magnetic collector, which is applied in the direction of non-detachable pipe connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of low mechanical energy conversion efficiency, etc. The effect of magnetic field energy

Active Publication Date: 2010-12-08

HARBIN INST OF TECH

View PDF4 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the angle between the side end surface and the axis of the magnetic collector structure for magnetic pulse forming and connection is between π / 6→π / 2, and the conversion efficiency of the magnetic field energy to the pipe deformation or the mechanical energy required for connection is low, and it is mostly used for protection. The role of coils and strengthening the structural strength of coils

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Sectional area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Login to View More

Abstract

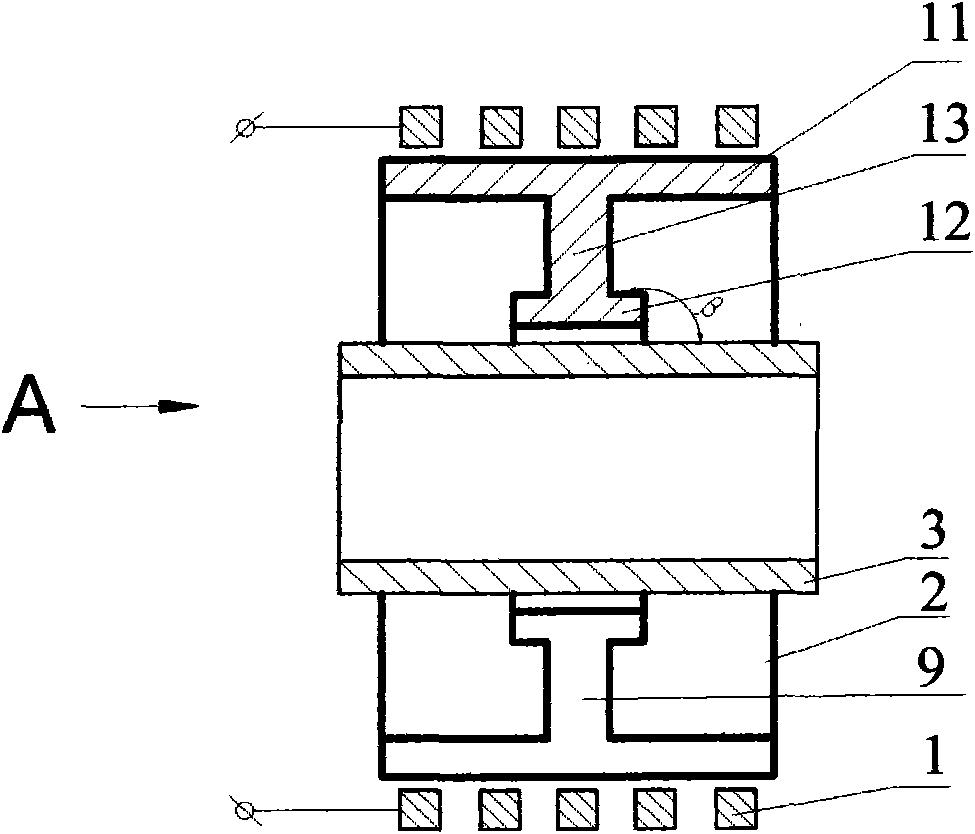

The invention discloses a magnetic concentrator structure for magnetic pulse formation, which relates to a device for forming and connecting a metal pipe by using a pulse magnetic field force. The included angle between the side end face and the axis of a conventional magnetic concentrator structure is between phi / 6 and phi / 2, so energy transfer efficiency and energy concentration efficiency of the magnetic field are low. The invention provides a novel magnetic concentrator, the longitudinal section structure of which is transverse H-shaped; the value of the oblique angle of the side end face of the magnetic concentrator structure depends on that the structure remarkably improves the magnetic field energy in a magnetic pulse formation discharge process so as to improve the energy conversion efficiency of the magnetic concentrator, further prolong the service lives of a coil and the magnetic concentrator, reduce the discharge voltage and the like.

Description

technical field The invention belongs to the magnetic pulse forming technology of metal pipe fittings, in particular to a device for forming and connecting metal pipe fittings by using pulsed magnetic field force. Background technique Magnetic pulse forming technology has the advantages of easy and precise control of processing energy, fast forming speed, high precision of formed workpiece, simple mold and strong versatility of equipment, and the whole forming process is pollution-free. It has been used in machinery, electronics, automobiles, aerospace and Weapons industry and many other fields. The basic principle of magnetic pulse shaping technology is the law of electromagnetic induction. A pulsed magnetic field passes through the workpiece and generates an induced current (also known as eddy current) on the workpiece. The magnetic field generated by the induced current interacts with the initial magnetic field to generate a huge pulsed magnetic pressure. When the magni...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21D26/14F16L13/02F16L13/14

Inventor 于海平李春峰

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com