Novel spraying nozzle without air-resistance and spray forming method thereof

A nozzle and aerosol technology, which is applied in the field of new aerosol nozzles and aerosol formation, can solve problems such as difficult to ensure no clogging, poor application environment, and cooling water cannot flow out normally, so as to avoid premature clogging and increase effective use Surface, atomization effect better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

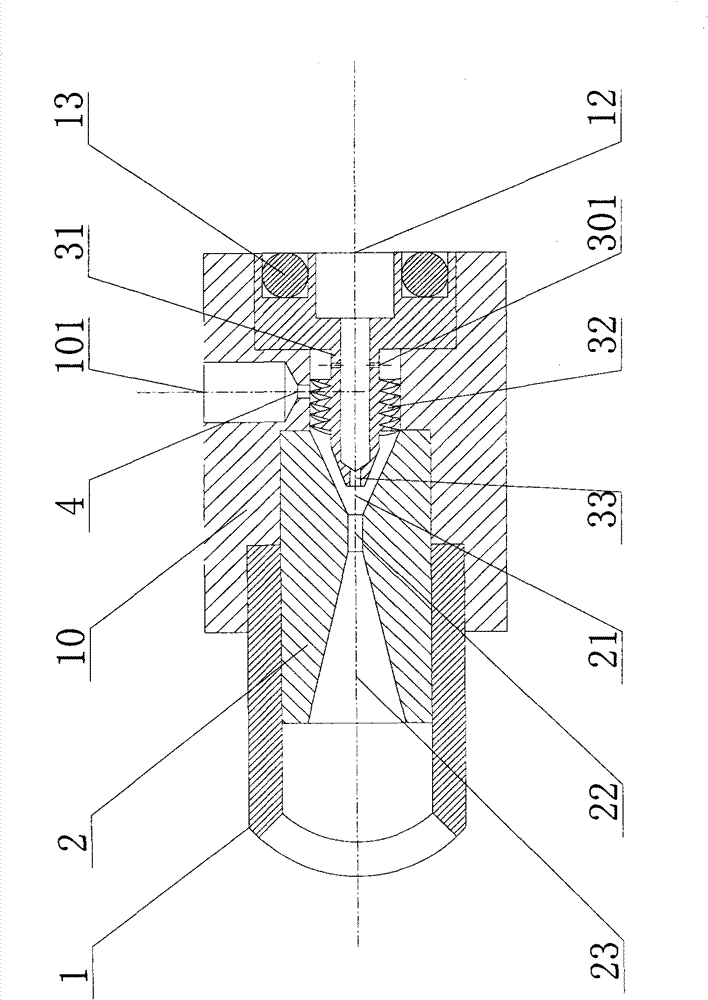

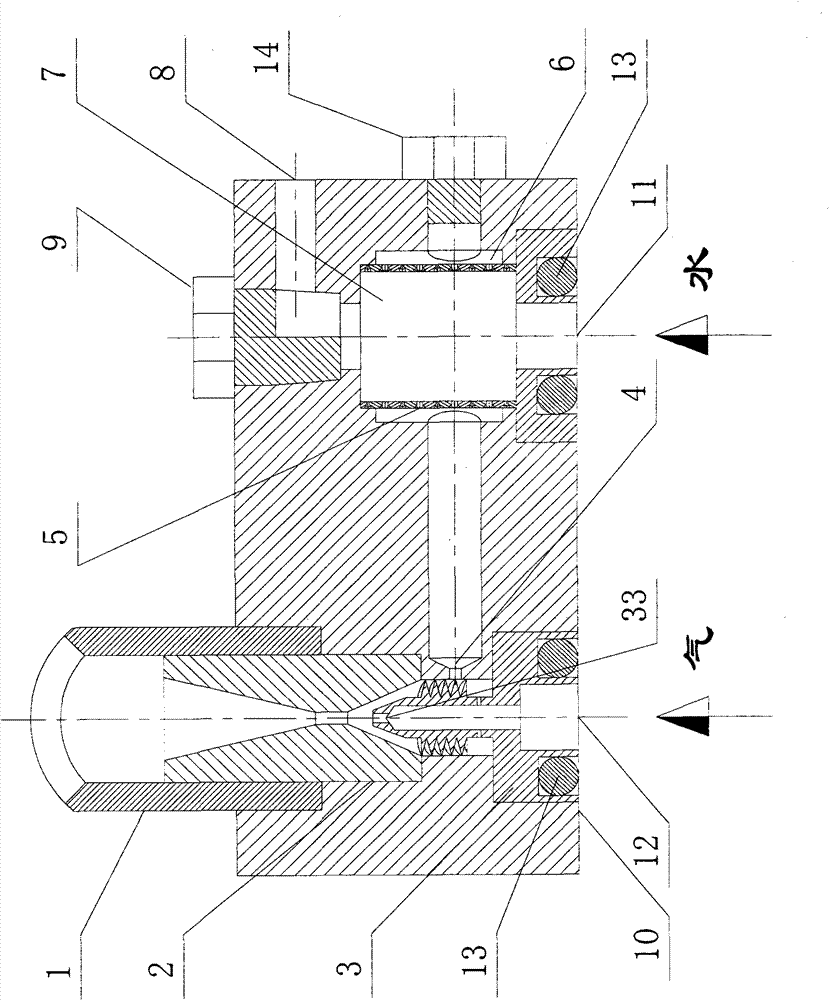

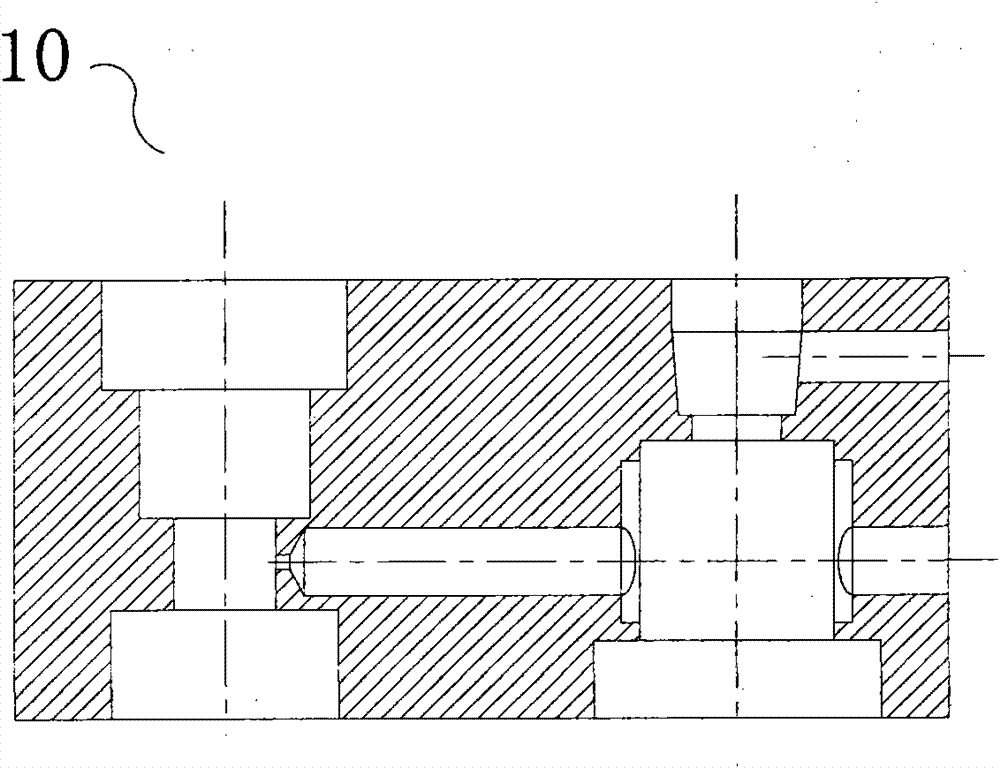

[0031] The invention proposes a novel air mist nozzle, in particular a non-air resistance air mist cooling nozzle. The aerosol nozzle includes: a nozzle base, the nozzle base includes a base body and a cavity, and the cavity includes a first fluid channel and a second fluid channel formed in the nozzle base; and a jet injector, the The jet injector comprises an injection pipe body and a Raoult tube type injection lumen, the injection lumen includes a tapered conical drainage section, a narrow mixing section and a gradually diverging inverted conical injection section; wherein , the first fluid channel and the second fluid channel merge at the end of the drainage section of the injection lumen, and the first fluid in the first fluid channel and the second fluid in the second fluid channel are fully mixed in the mixing section of the injection lumen , and atomized and sprayed out from the injection section. Since the present invention adopts the ejection principle of the jet in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com