Drip-proof throttling nozzle device and usage thereof

A nozzle device and anti-drip technology, which is applied in the direction of spraying devices, spraying devices, etc., can solve the problems of railway transportation safety hazards, waste of residual liquid resources, increased labor workload of workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

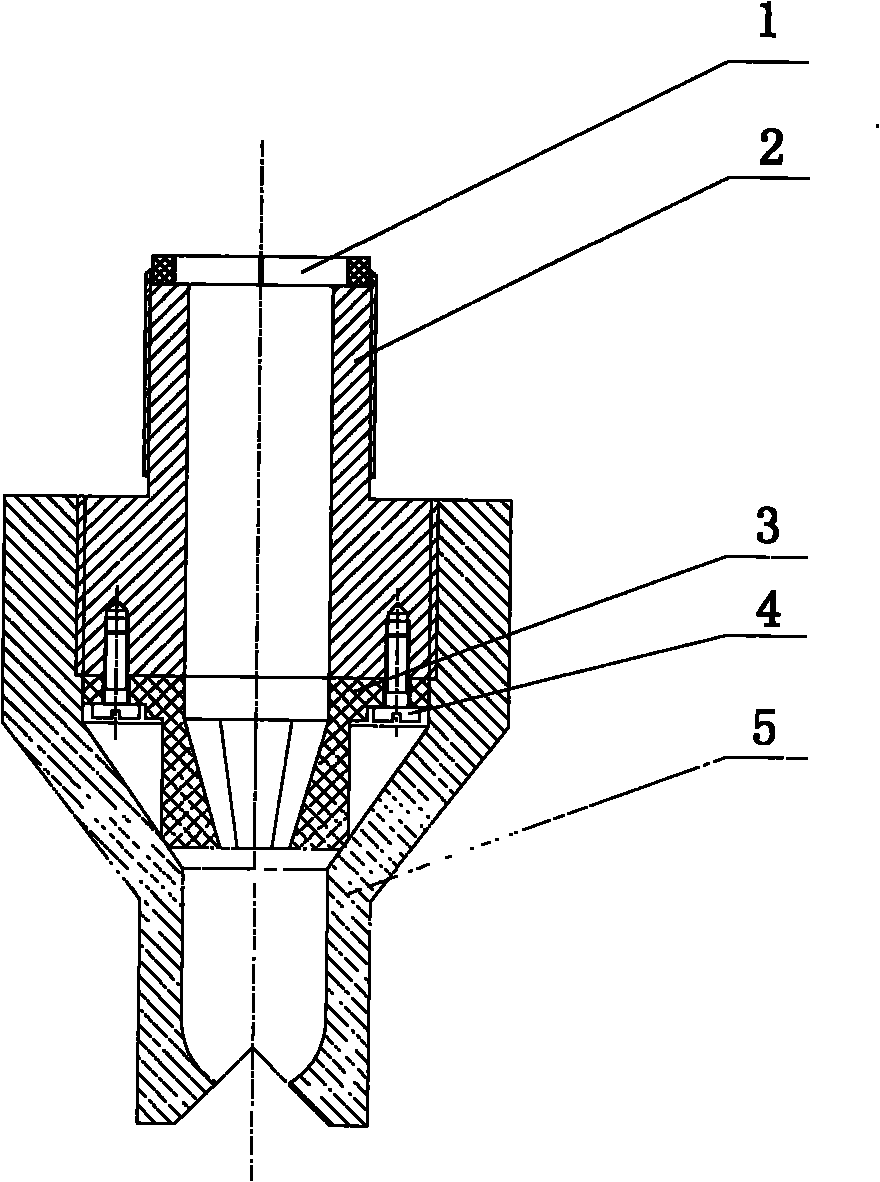

[0026] A drip-proof and throttling nozzle device of the present invention and its application method in conjunction with its application in train antifreeze spraying devices will be further described in detail below in conjunction with the accompanying drawings.

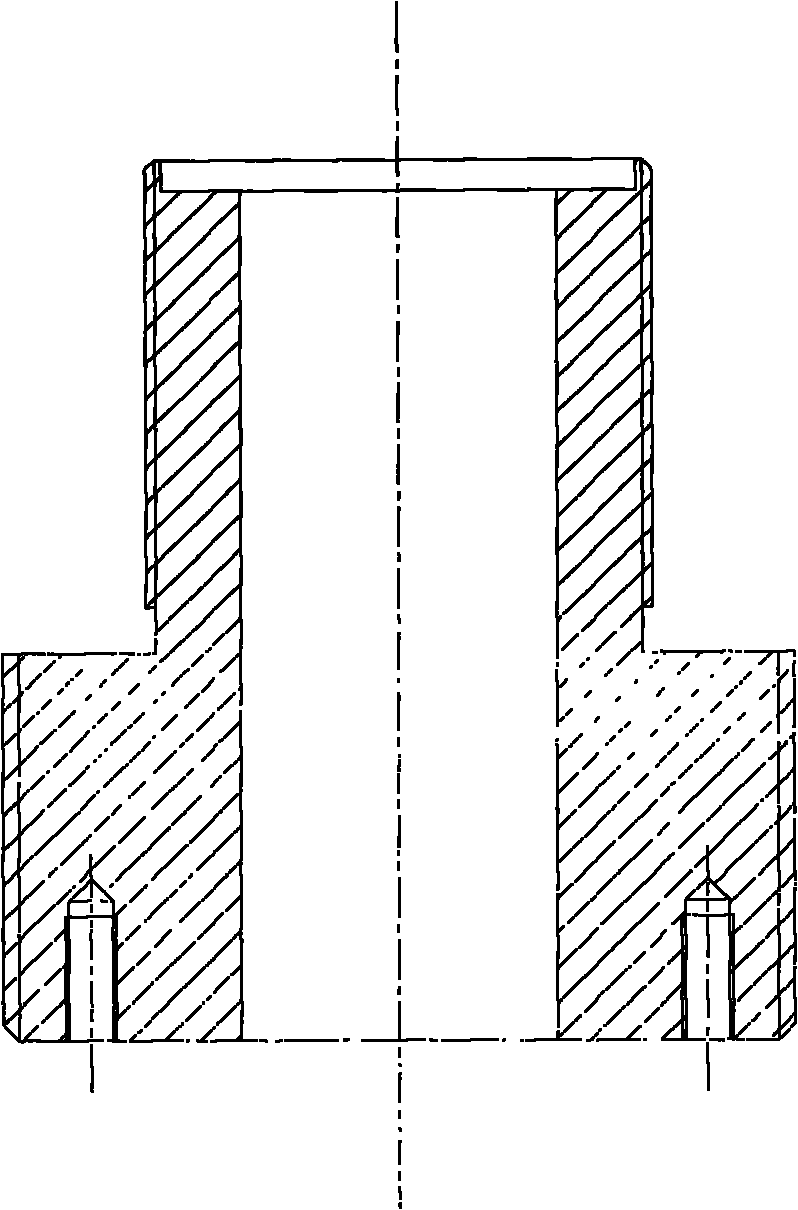

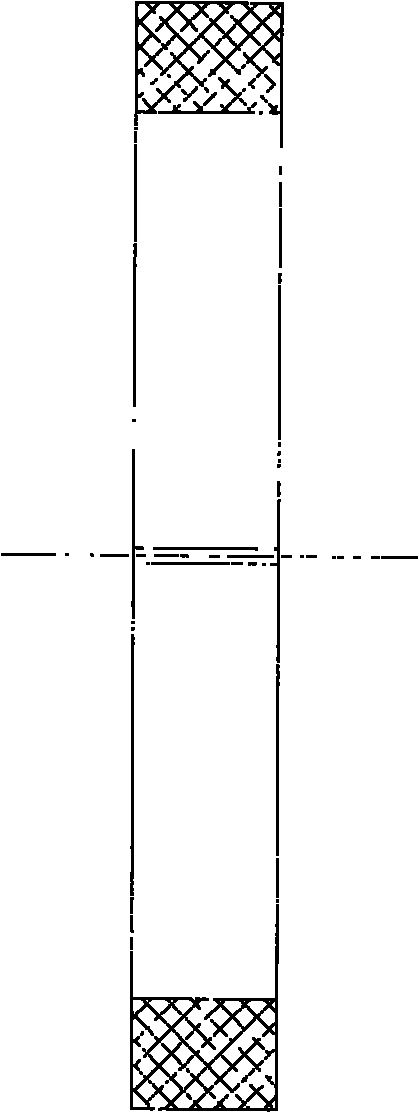

[0027] Such as figure 1 As shown, a drip-proof and throttling nozzle device of the present invention is composed of a gap diaphragm 1, a nozzle top core 2, a nozzle bottom core 3, a slotted pan head screw 4 and a nozzle cover 5. The gap diaphragm is placed in the circular groove on the upper end surface of the nozzle top core 2; the outer part of the nozzle top core 2 has metric threads at both ends on the two cylindrical surfaces with different radii, and the metric thread on the cylindrical surface with the smaller radius The thread is used for the connection between the nozzle top core 2 and the antifreeze liquid delivery pipeline, and the metric thread on the cylindrical surface with a larger radius is used for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com