Wire winding method and wire winding machine

A winding method and winding machine technology, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

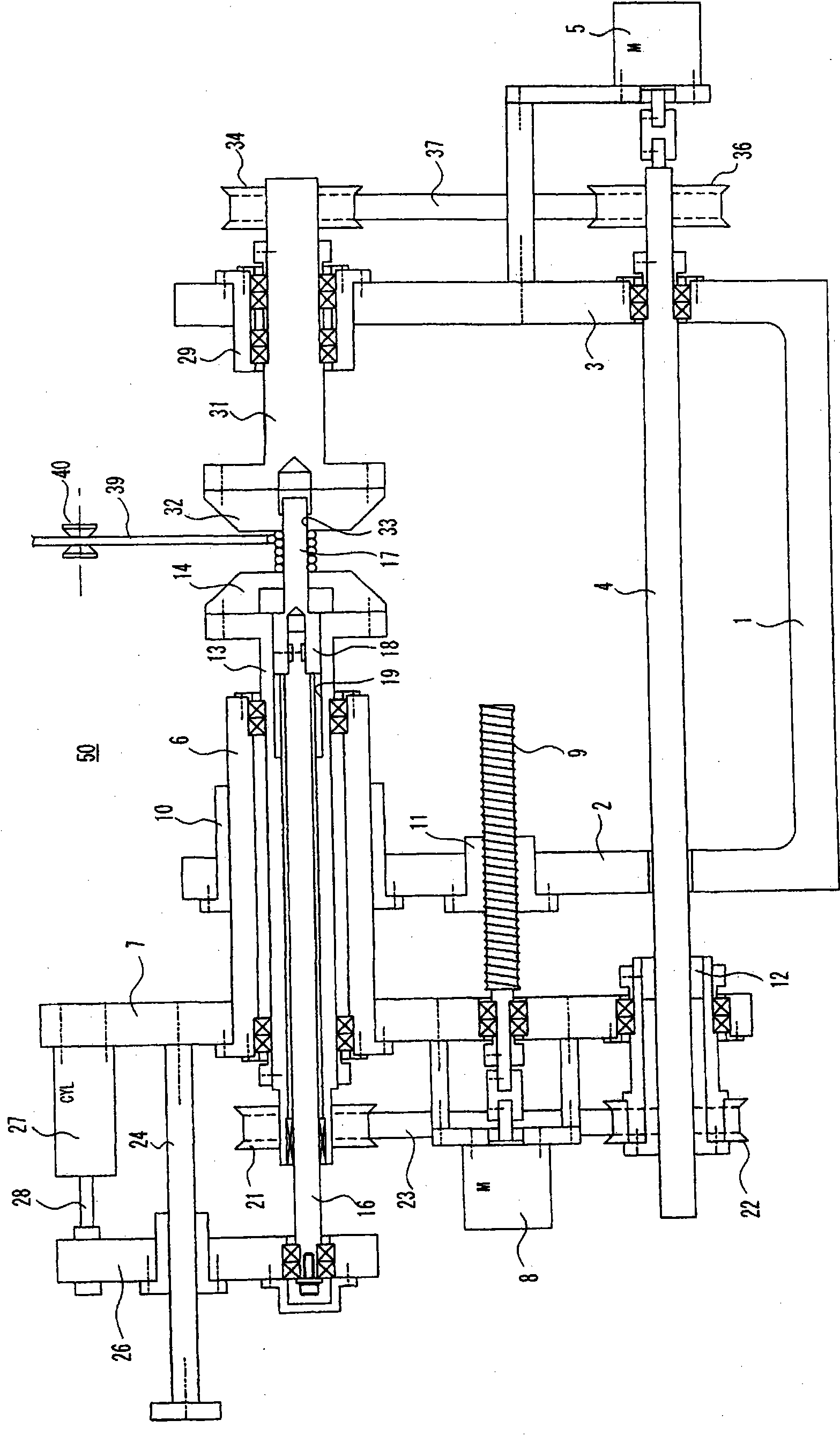

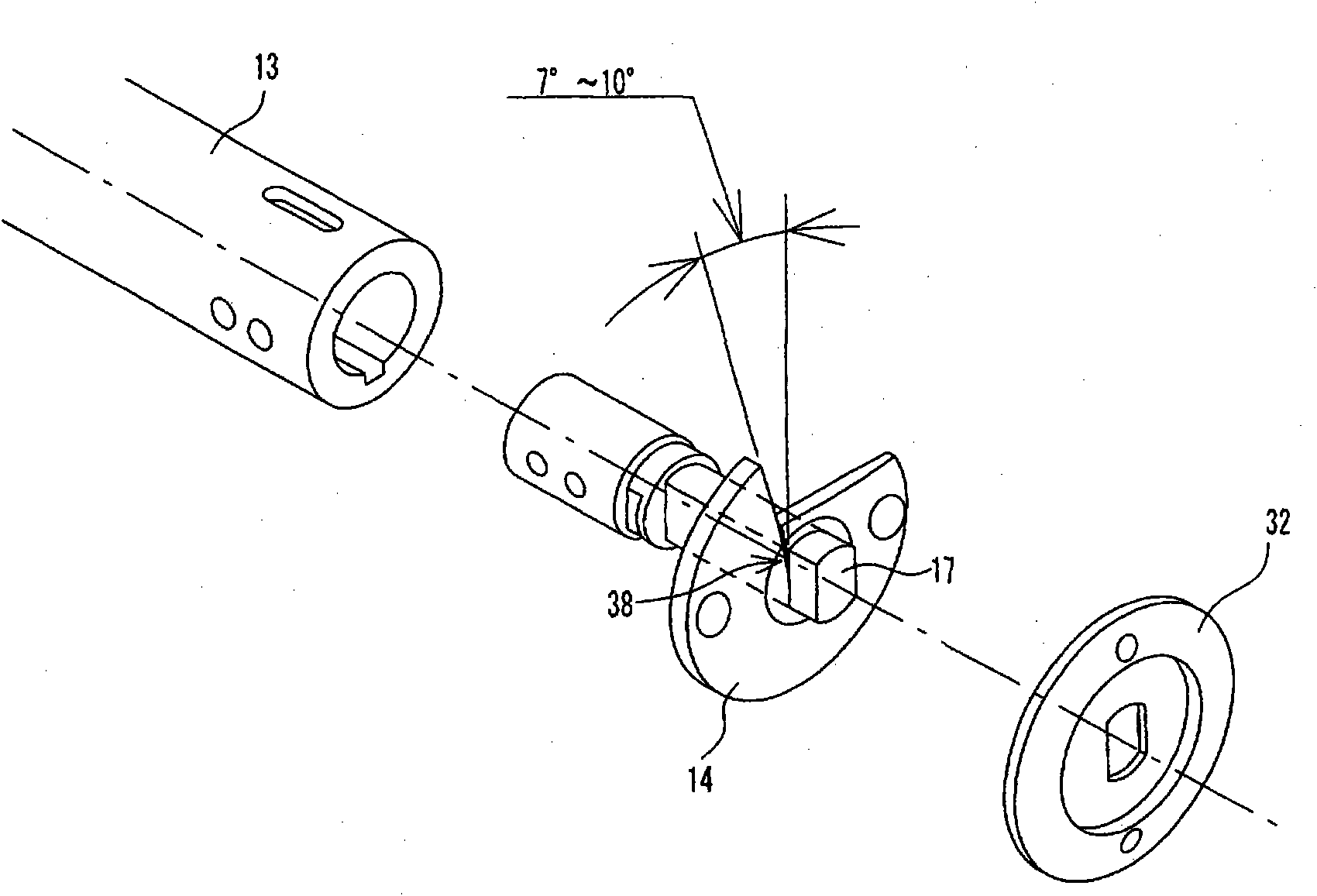

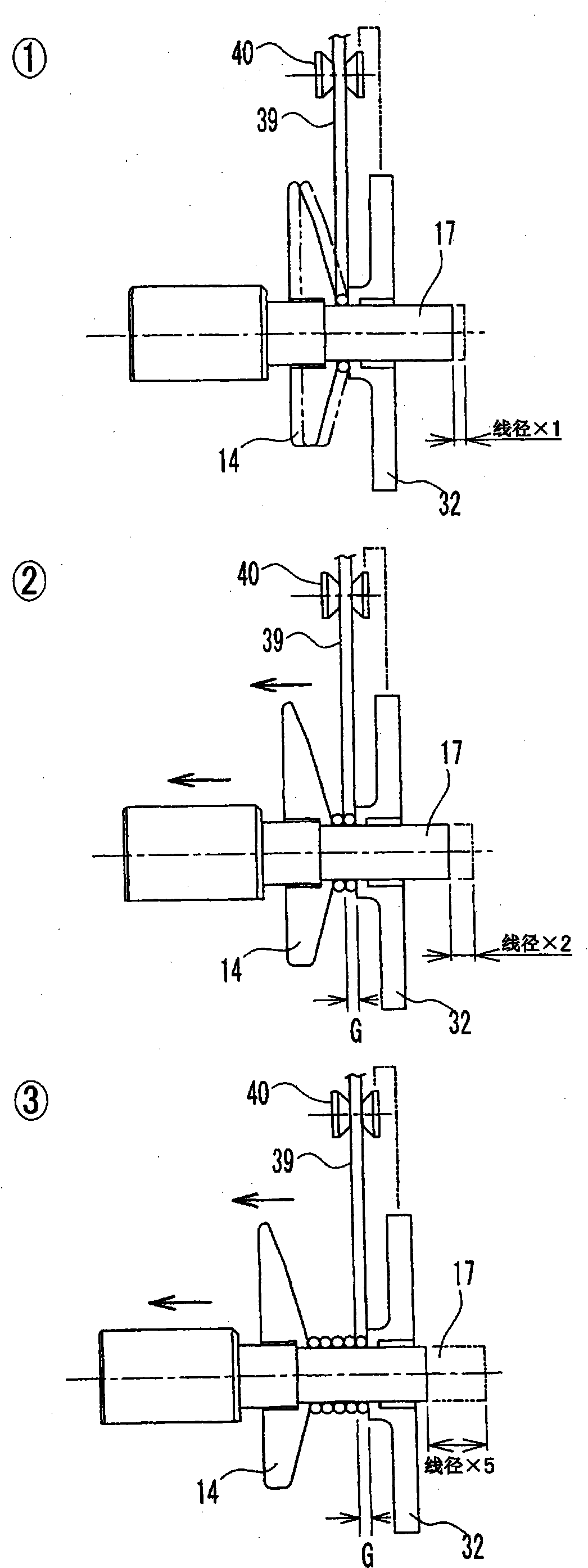

[0121] Hereinafter, the present invention will be described in detail based on the drawings and examples. figure 1 It shows the front of the winding machine 50 in an Example. In principle, each part is shown in section, but hatching is not used because it is difficult to see clearly. Figure 3 ~ Figure 6 the same. figure 2 The movable-side reel 14, the fixed-side reel 32, the winding mandrel 17, and the like are shown. about the figure 2 , are only marked with symbols, and their descriptions are omitted. In addition, regarding the structure of the winding machine, centering on the above-mentioned publications, Japanese Patent Application Laid-Open No. 2005-116657, Japanese Patent Publication No. 2001-358029, Japanese Patent Publication No. Hei 10-304628, etc. It is well known. Therefore, only the parts considered necessary for the description of the embodiment will be described here.

[0122] figure 1 Among them, 1 is the base, and the left side of the main body 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com