Interrupting chamber, HVDC bypass interruptor and HVDC-conversion substation with such a chamber

A hollow, flow path technology, used in high-voltage air circuit breakers, circuits, electrical switches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

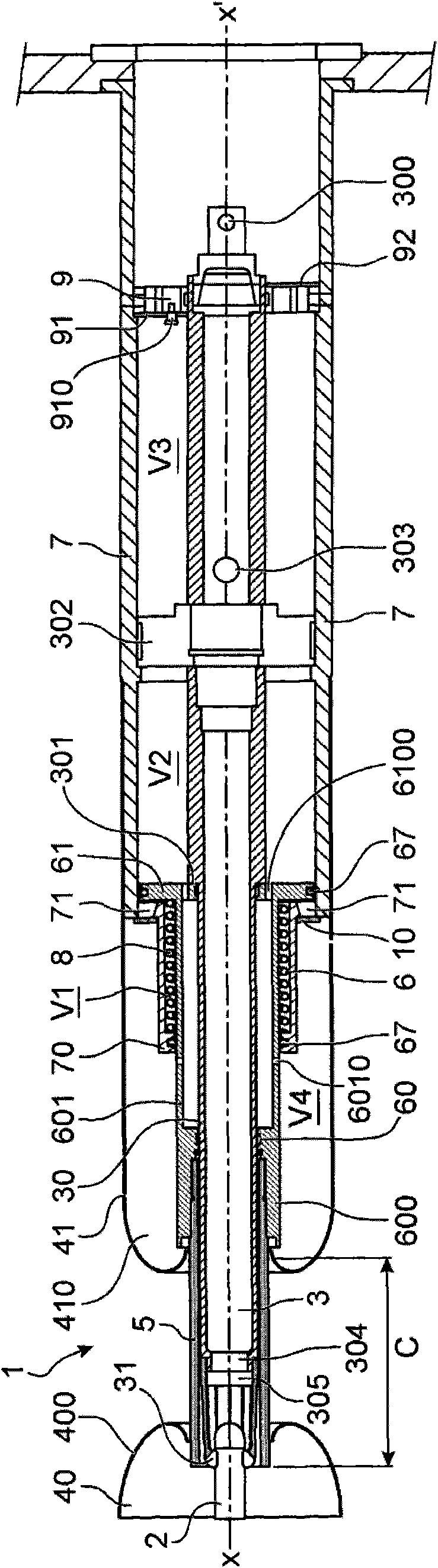

[0056] It may be repeated here that the terms "upstream" and "downstream" are to be understood relative to the direction of flow of the blown gas used to interrupt the arc.

[0057] Therefore, during any operation of disconnecting an interrupter having an interrupting chamber within the scope of the present invention, Figures 2A to 2C The upstream end of the blown jet in appears in volume V3, and the blowout occurs towards the downstream side (that is, from right to left).

[0058] Referring to the arcing contact 3, the hollow tube 30 is upstream of a constriction 304 of the gas flow cross-section, which is itself in a wider portion 305 immediately upstream of the real contact portion 311 (contact portion proper) upstream.

[0059] The respective gas flow cross-sections S1 , S2 and S3 of the actual contact portion 31 , of the constriction 304 and of the wider portion 305 are the cross-sections through which the blown gas flows.

[0060] Figure 2B and 2C The interrupting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com