Air Compressor Station Predictive Adjustment Control Method

A technology of pressure regulation control and predictive control, which is applied in the direction of pump control, electric fluid pressure control, and electrical program control, etc. The effect of unloading operation, avoiding pipeline venting operation, and pressure balance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

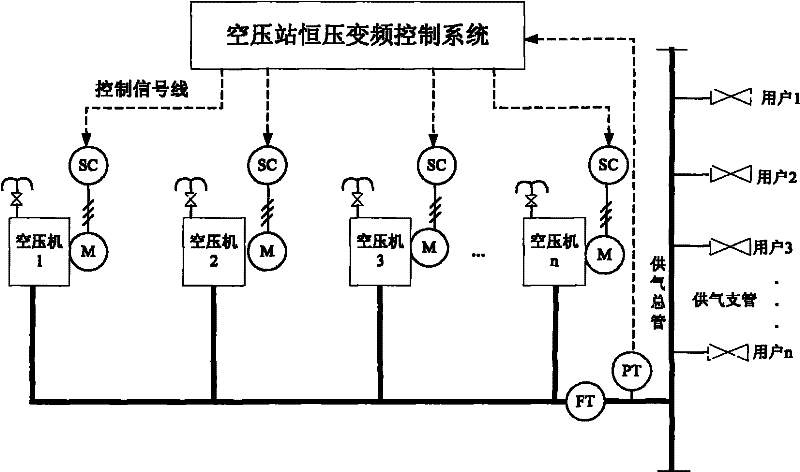

Problems solved by technology

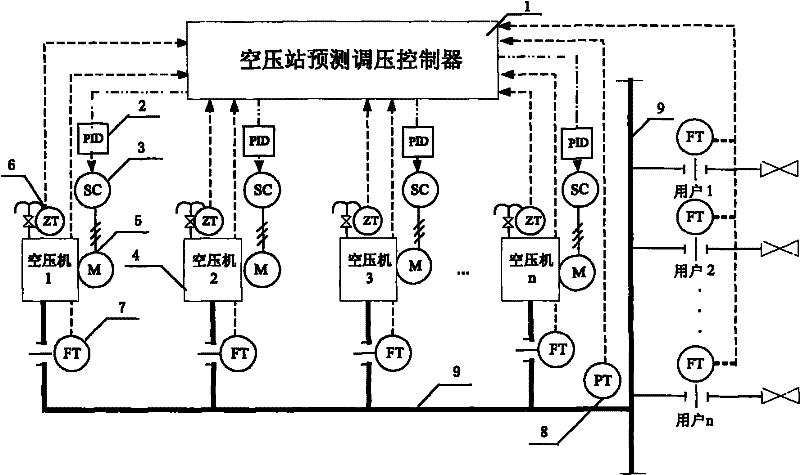

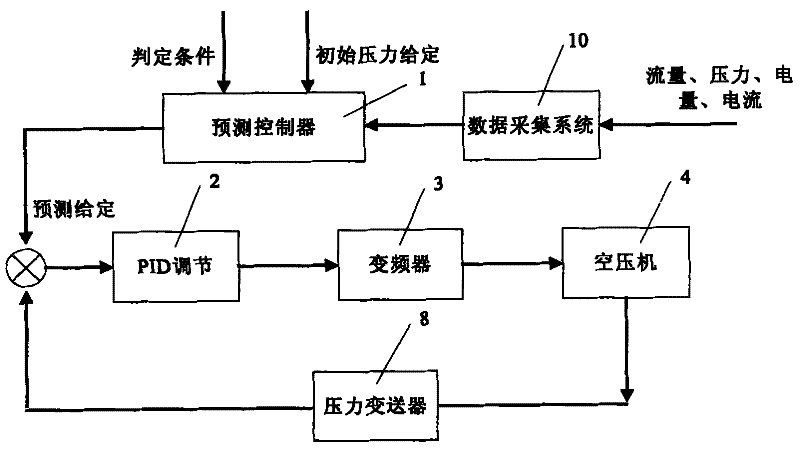

Method used

Image

Examples

Embodiment

[0060] For an air compressor station with 4 air compressors, after starting, the motor current is 100% of the rated current, the opening of the vent valve is 0%, and the flow rate is 100% of the rated flow rate. No. 1 to No. 4 air compressors are all loaded state, the given value of pipe network pressure is 0.7MPa. According to the calculation, the given values of the frequency converters of the four air compressors are (100%, 100%, 100%, 100%). When the pressure of the pipe network is greater than 0.7MPa, the motor current of the air compressor is 20% of the rated current , the flow rate is 15% of the rated output flow rate, the air compressor enters the critical unloading state, the given value obtained by calculation is (0%, 100%, 100%, 80%), and the No. 1 air compressor is automatically in the standby state. No. 4 air compressor is in the 80% load state, and the constant pressure control is realized through pressure regulation.

[0061] When the given value of the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com