Furnace liner for vertical coal mine ventilation air methane oxidation device

An oxidation device and wind gas technology, applied in the direction of gas discharge, safety devices, mining equipment, etc., to achieve the effect of reducing construction volume, reducing costs, and improving heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

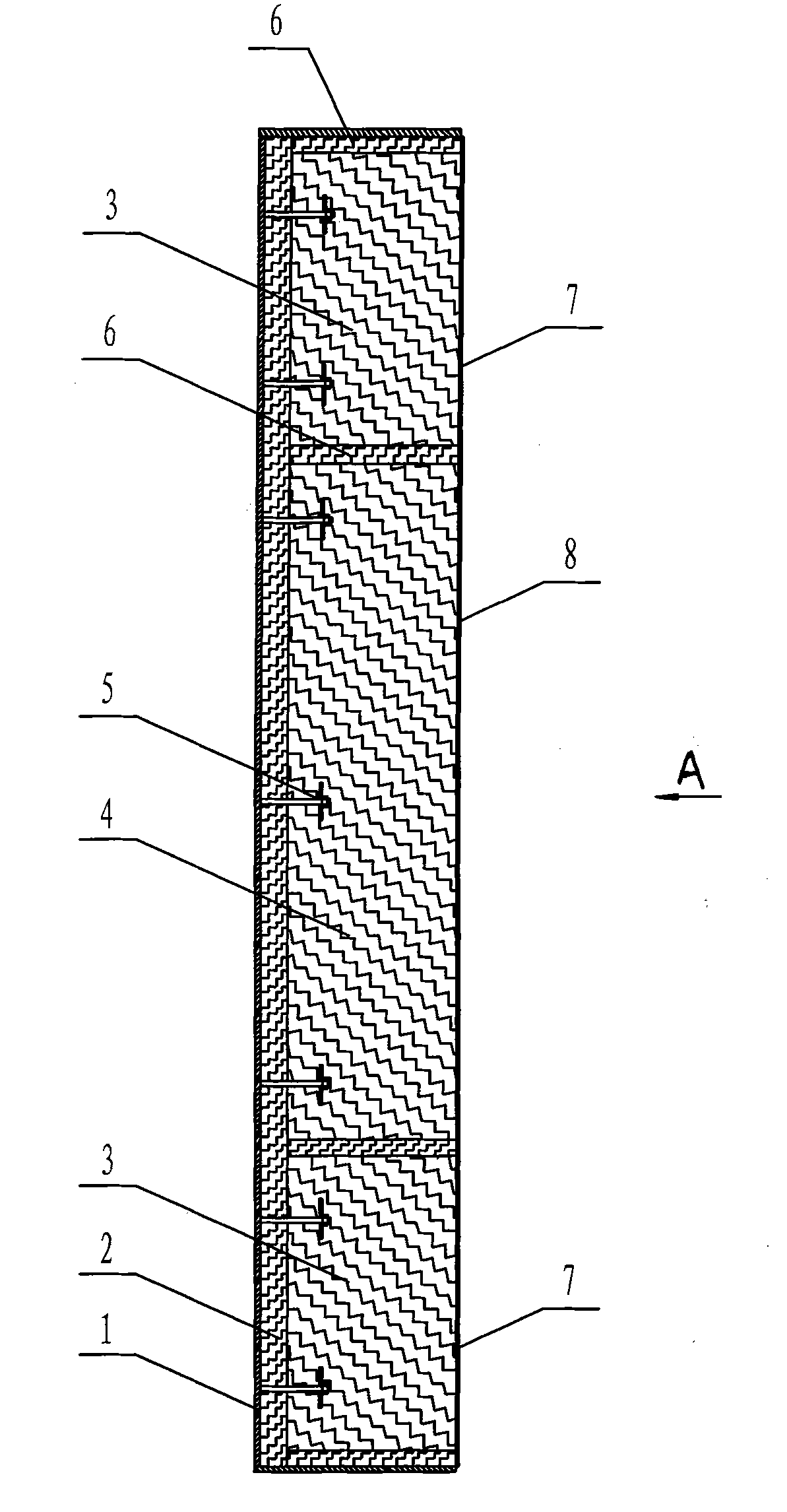

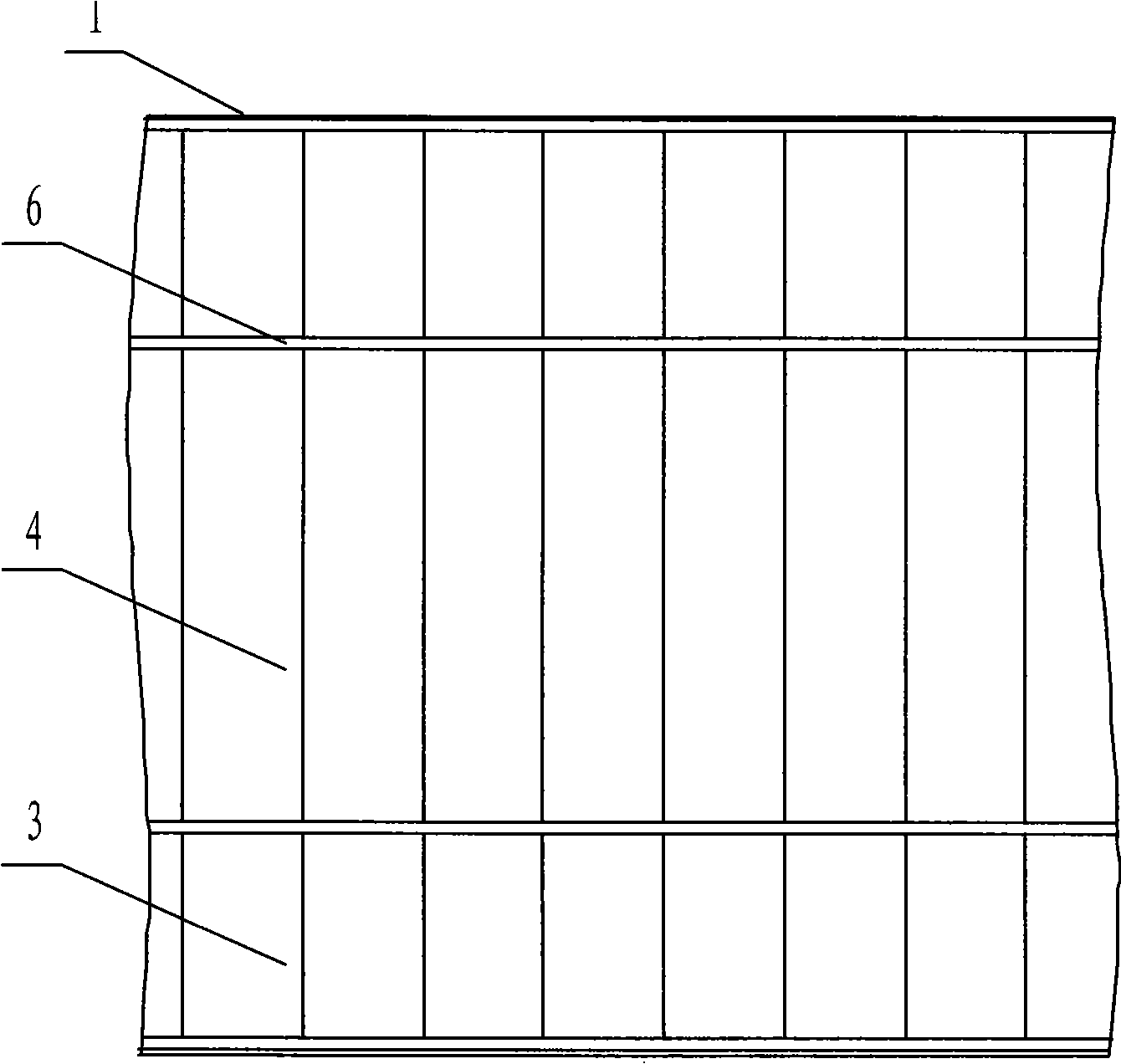

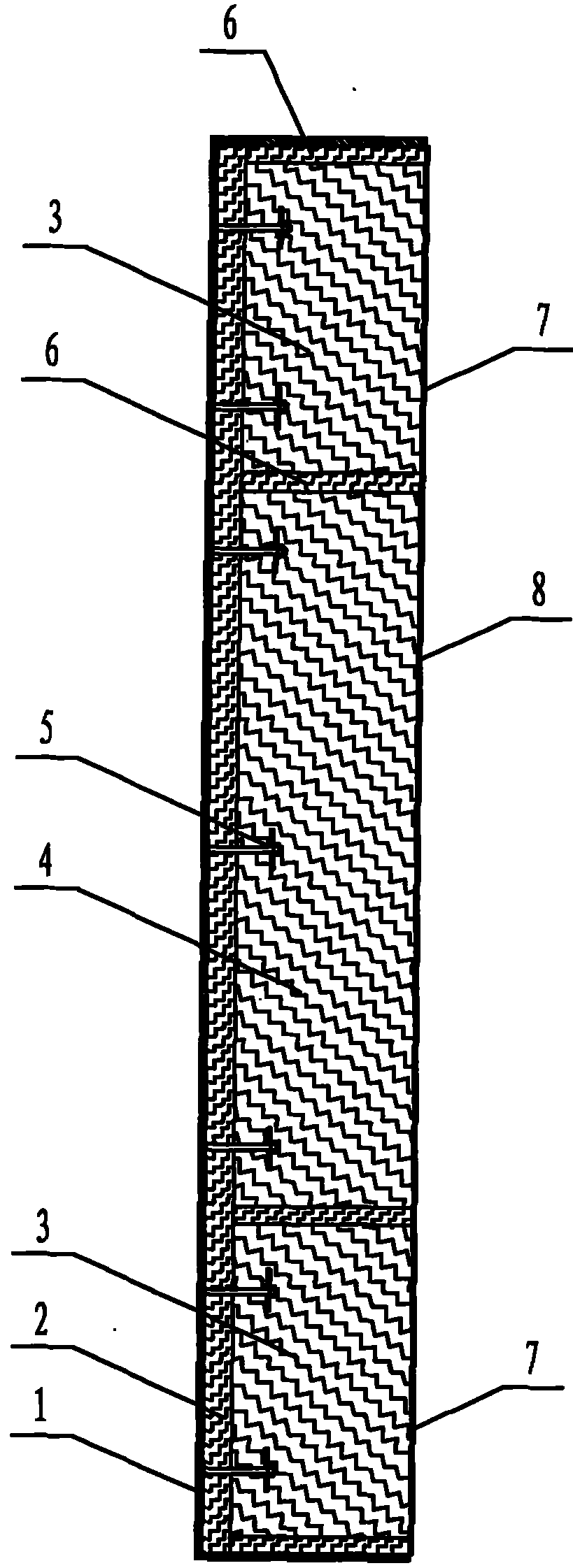

[0018] exist Figure 1-2 In the shown embodiment, the furnace lining height is 2300 mm, including a shell 1 , a ceramic fiber blanket 2 , a plurality of anchors 5 , and a wall composed of short ceramic fiber modules 3 , long ceramic fiber modules 4 , and compensation blankets 6 . Wherein the long ceramic fiber module 4 corresponds to the high temperature zone of the furnace body, the size of a single long ceramic fiber module 4 is 1200mm×300mm×300mm, and the volume density is 220-250kg / m 3 , the working temperature is ≥1350°C, the short ceramic fiber module 3 corresponds to the low temperature zone of the furnace body, the size of a single short ceramic fiber module 3 is 500mm×300mm×300mm, and the bulk density is 200-220kg / m 3 , Working temperature ≥1000℃. The upper and lower ends of the short ceramic fiber module 3 are provided with a compensation blanket 6, and the upper and lower ends of the long ceramic fiber module 4 are provided with a short ceramic fiber module 3 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com