Gear cutting machine

A technology for gear cutting machines and grinding tools, which is applied in the directions of gear cutting machines, gear teeth, mechanical equipment, etc., to avoid different positions and shorten the time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

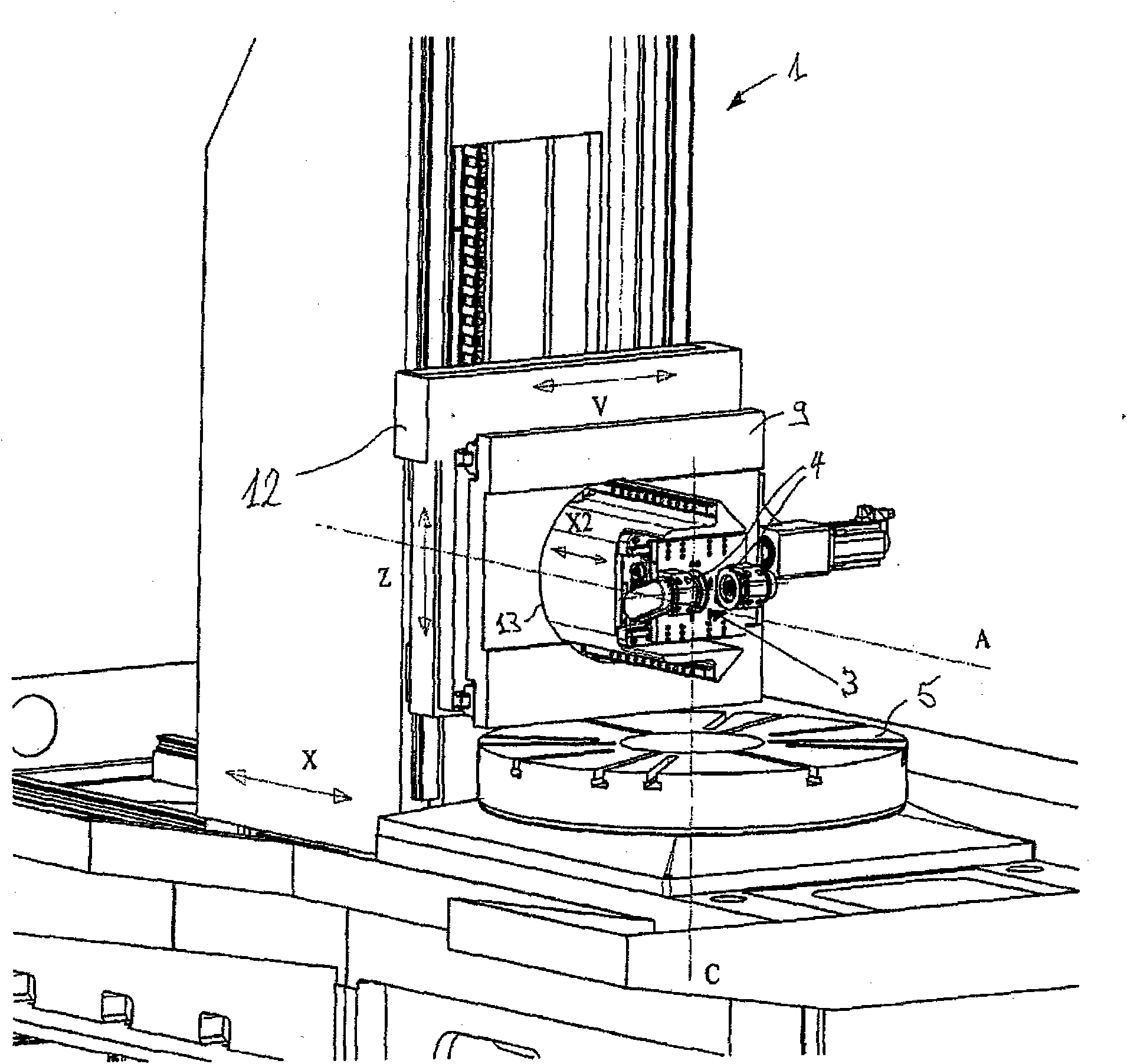

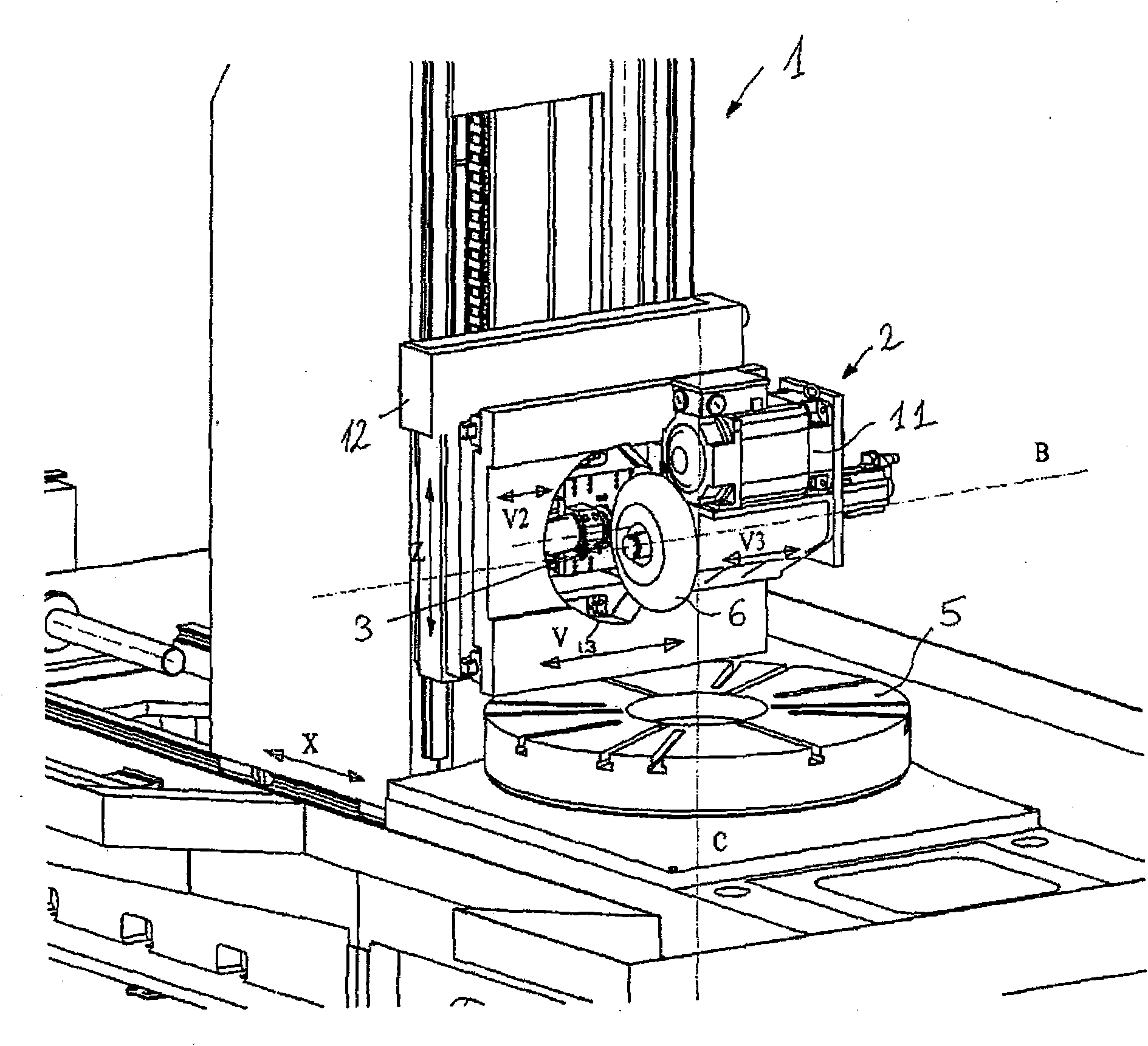

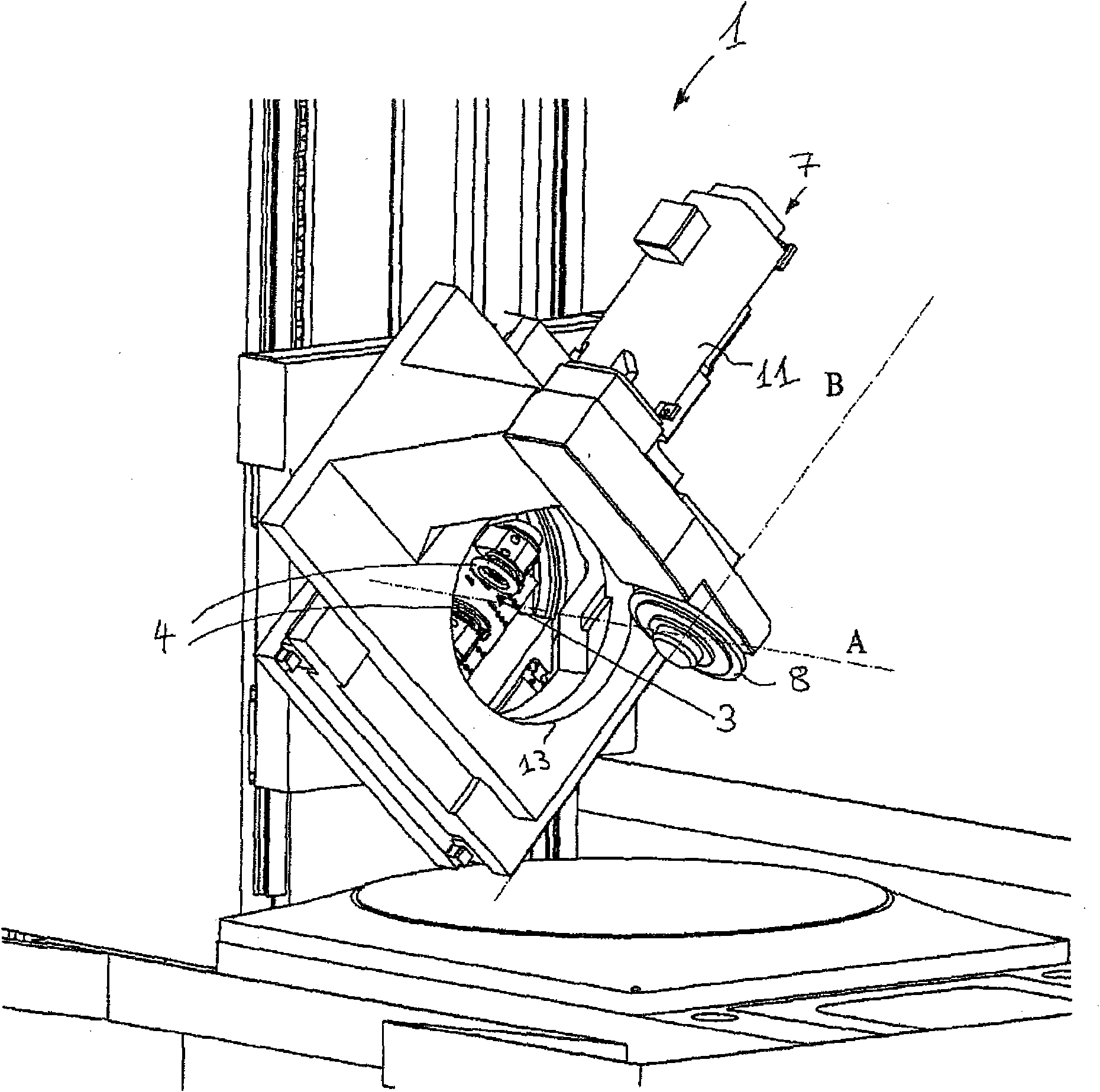

[0033] will refer to figure 1 The general design of the gear cutting machine is described in more detail. It has a machine table 5 for mounting a tool receiver and on which a workpiece can be clamped. In this respect, the machine table 5 is rotatable about an axis C, which is advantageously positioned in a vertical manner. As an alternative, however, horizontally positioned workpiece receivers can also be used. Gear cutting machine 1 also has a tool for mounting processing heads 2, 7 (respectively see figure 2 and image 3 ) of one or more mounting surfaces 9. An external grinding head 2 for machining the outer contour of a workpiece or an inner grinding head 7 for machining the inner contour of another workpiece can be mounted on the gear cutting machine 1 (see respectively figure 2 and image 3 ). One or more grinding tools 6 , 8 can be clamped on the respective machining head 2 , 7 . In this respect, the grinding tools 6 , 8 are arranged to be rotated by the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com