Continuous autoclave

A sterilization kettle and tank technology, which is applied in the fields of food science, food preservation, and application, to increase the sterilization time, improve the sterilization effect, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

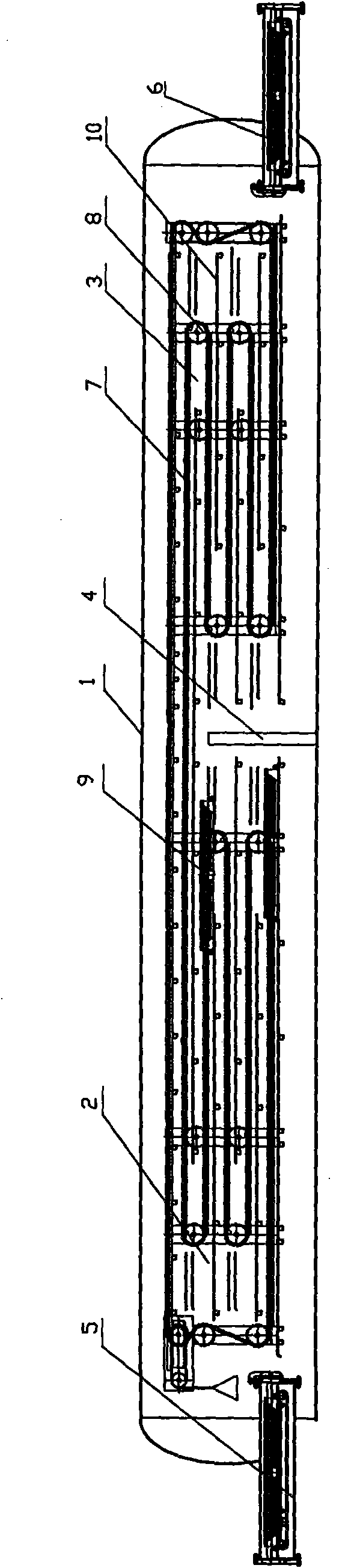

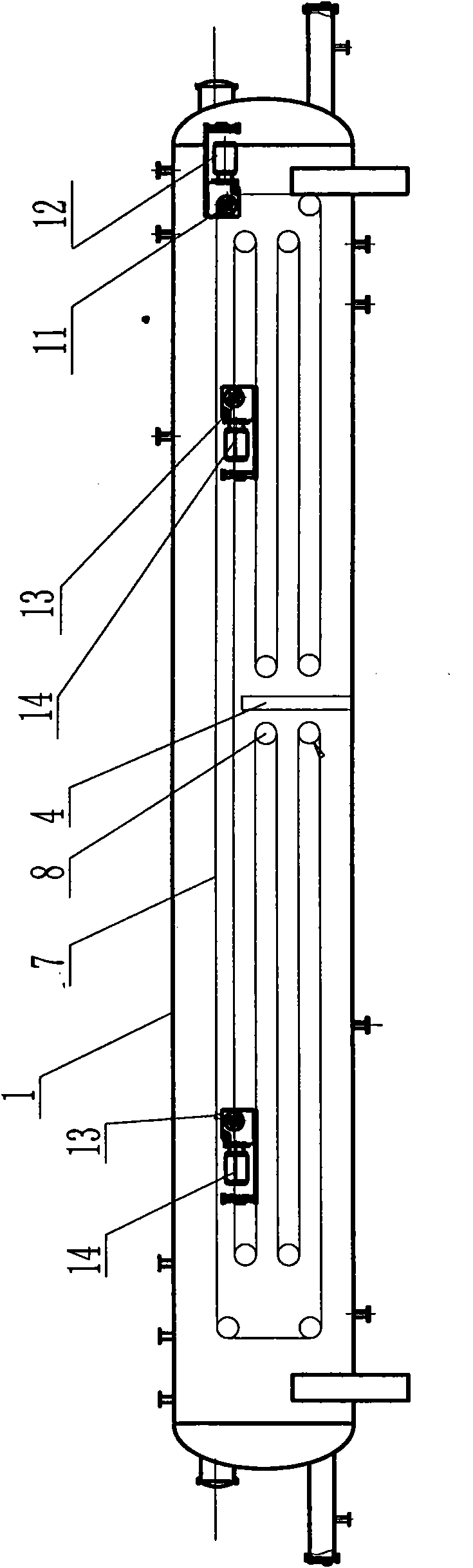

[0020] Such as figure 1 The shown embodiment is a continuous sterilizing kettle in a chain transmission mode, including a tank body 1, a material conveying device composed of a multi-layer continuous transmission chain 7 and a number of sprockets 8 installed in the tank body, and a container for holding materials and a The cage frame 9 that runs continuously along the upper and lower guide rails 10 is driven by a chain transmission device. The tank body 1 is equipped with a high-temperature hot water sterilization cabin 2 and a low-temperature cold water cooling cabin 3, and the isolation plate 4 standing in the middle of the tank body 1 separates the sterilization cabin. The high-temperature hot water in 2 is isolated from the low-temperature cold water in the cooling chamber 3, and the material inlet and material outlet ends of the tank are respectively equipped with an inlet transition chamber 5 and an outlet transition chamber 6, so that the materials can adapt to the steri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com