Stoker-fired boiler, a method of modernization of stoker-fired boilers and a method of elimination of uncontrolled leakages of air not taking part in the combustion process in a stoker-fired boiler

A stoker and boiler technology, which is applied to a boiler that uses a stoker to add coal, can solve the problems of airflow leakage, the boiler cannot be guaranteed to be completely sealed, etc., and achieve the effects of reducing emissions, reducing physical losses, and reducing dust emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

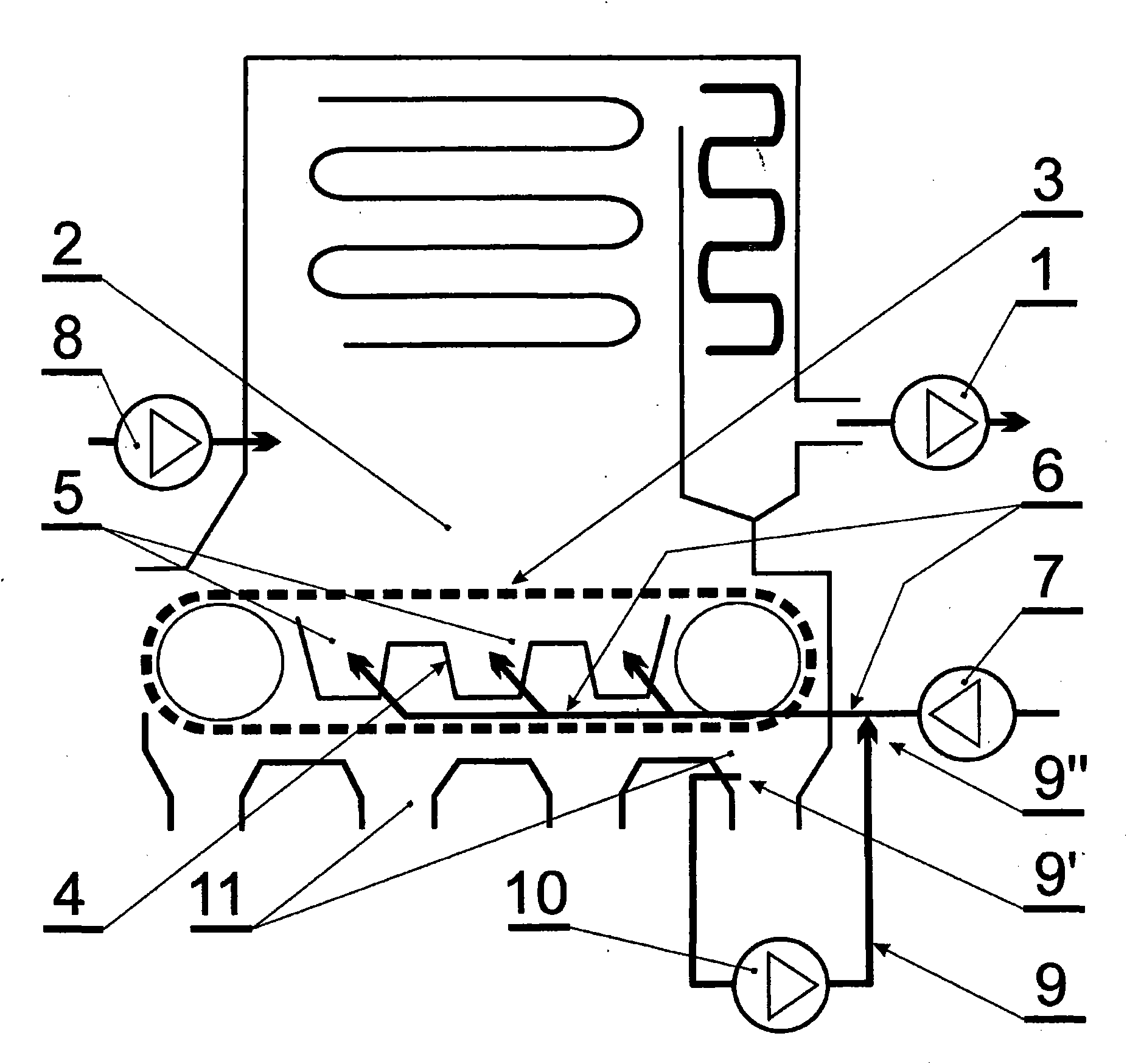

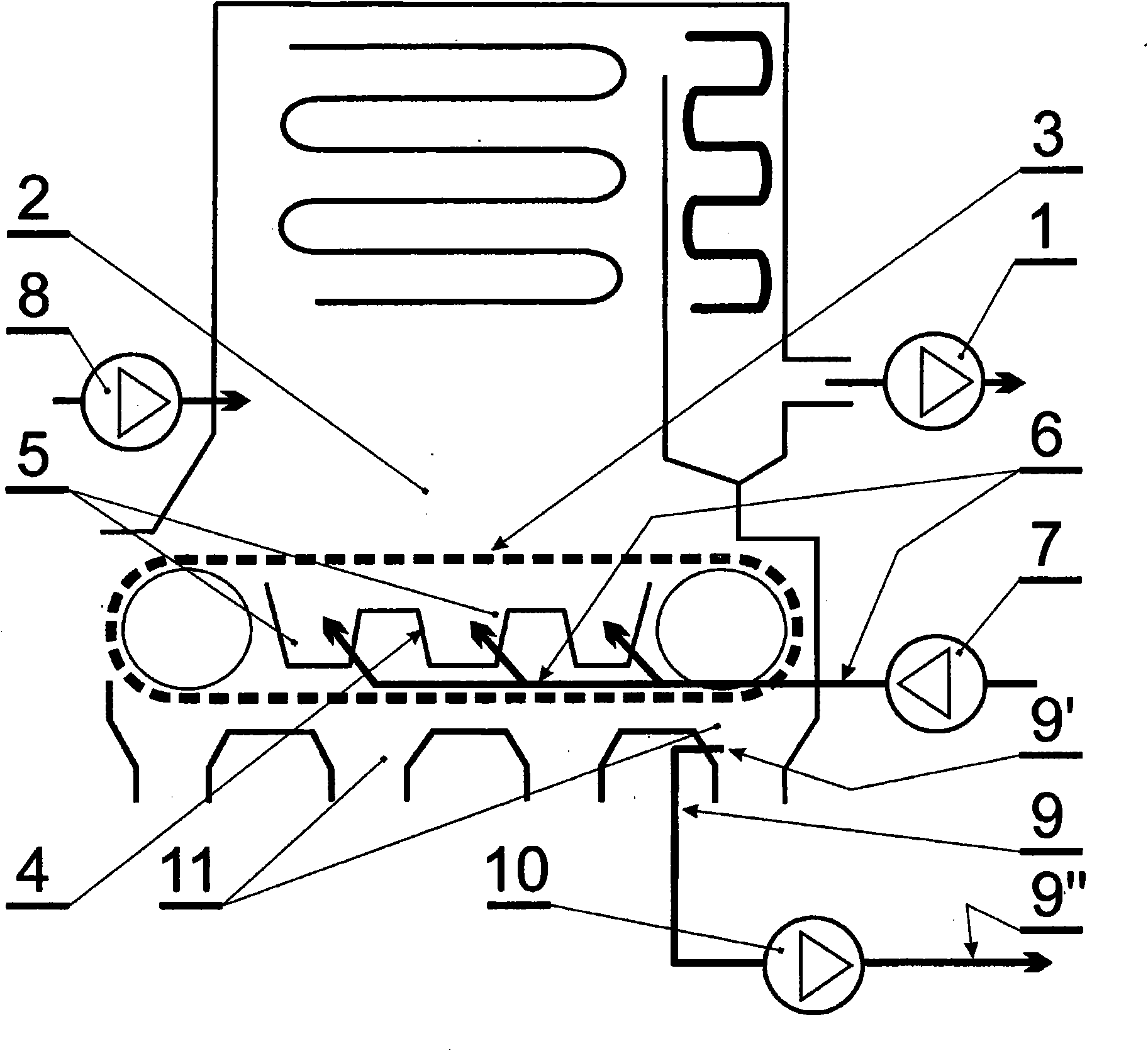

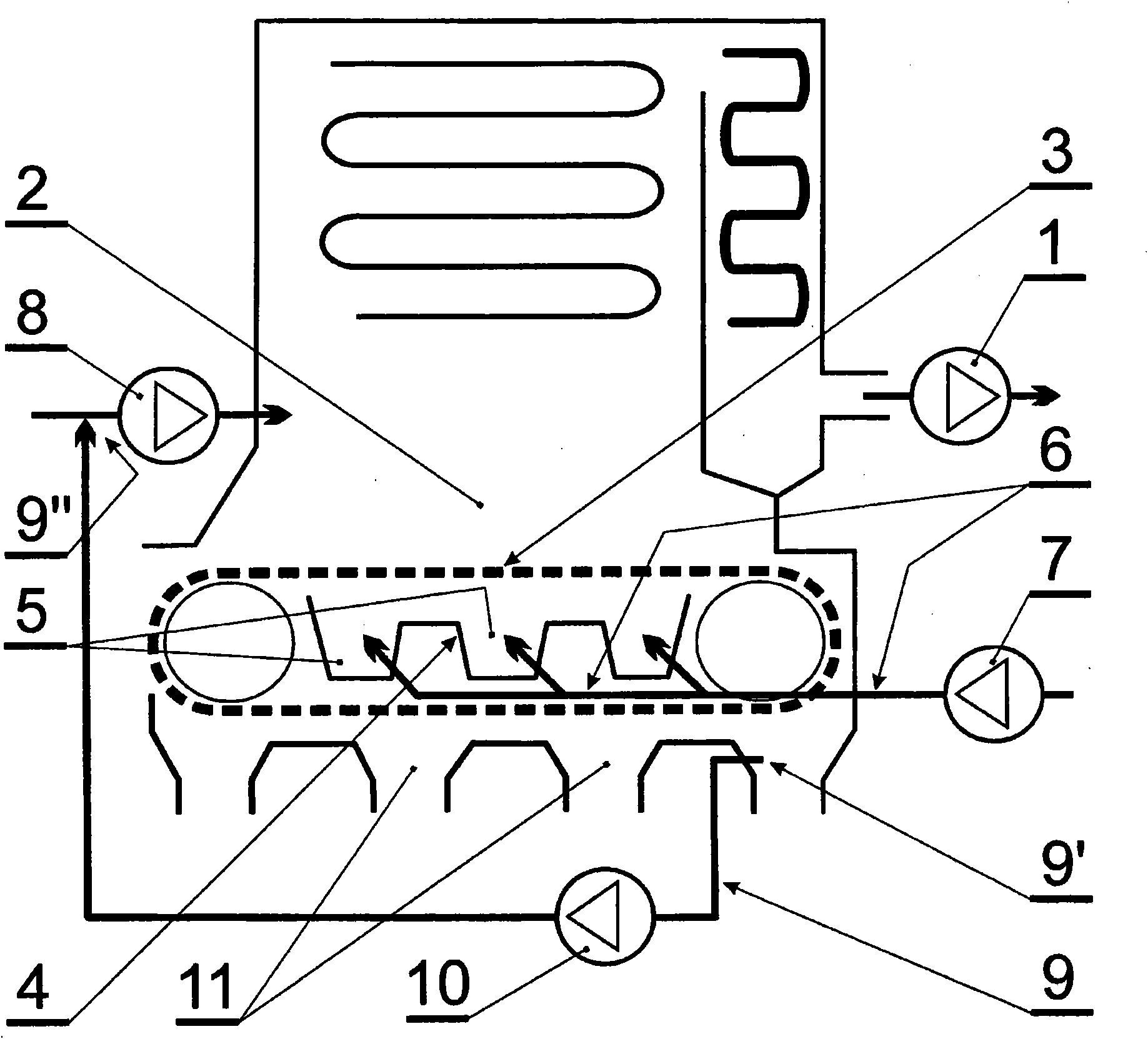

Embodiment Construction

[0015] A typical stoker stoker boiler has a flue gas area with a flue gas exhaust fan 1, and a burner area. In the burner zone there is a combustion chamber 2, a movable mechanical stoker 3, a stoker lower windbox system 4 with a windbox 5, and channels for supplying air from the atmosphere to the inside of the windbox 5 by means of a bellows ventilation fan 7 6. The combustion chamber 2 has a secondary air passage powered by a fan 8 . The boiler according to the invention has an additional air channel 9 with a built-in fan 10 with adjustable output. One end 9' of the extra air channel 9 is connected to the space under the stoker located outside the wind box 5 of the stoker lower bellows system 4, and the other end 9" of the extra air channel 9 can supply external air to the stoker The space connection of the channel 6 of the air box 5 of the lower air box system 4 is either to the atmosphere or to the secondary air channel of the combustion chamber 2. By controlling the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com