Bactericidal cleanser composition

A technology of bactericidal cleaning agent and composition, applied in detergent compositions, surface active detergent compositions, bactericides, etc., can solve the problems of poor foam shape retention, slow drying, residual stickiness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~67、 comparative example 1~17

[0084] The sterilizing cleaning agent composition of the composition shown in Tables 1-14 was prepared according to the usual method, and the pH of the composition was adjusted to about 5.6. Viscosity (25° C.) of the sterilizing and cleaning composition of Examples was measured using a rotational viscometer (manufactured by Tokyo Keiki Co., Ltd., type B8L) with a No. 1 rotor speed of 60 rpm for 60 seconds. The result was 1 to 9 mPa·s. 200 g of the obtained disinfectant cleaning composition was filled in a 250 mL foamer container. The use specification of this foaming container is based on the method described in Japanese Patent Application Laid-Open No. 2005-193972, using trade name W-5721, WP.FT L nozzle (manufactured by Yoshino Industry Co., Ltd.). Specifically, a gas / liquid volume ratio: 13 / 1, a discharge amount: 1 g (1 squeeze), a diameter of 5 mm × 8 mm (ellipse), and a foam forming member: 1 sheet each of 200 mesh and 305 mesh porous membranes were used. bubbler contain...

Embodiment 68

[0166] According to the following composition, the whole body sterilizing cleanser composition of Example 68 was prepared according to the usual method. The obtained whole body antiseptic cleansing composition was filled in a foaming container in the same manner as in Example 1, and the same evaluation was performed. (pH5.6, viscosity (25°C), 4mPa·s)

[0167] [Table 15]

[0168] Composition %

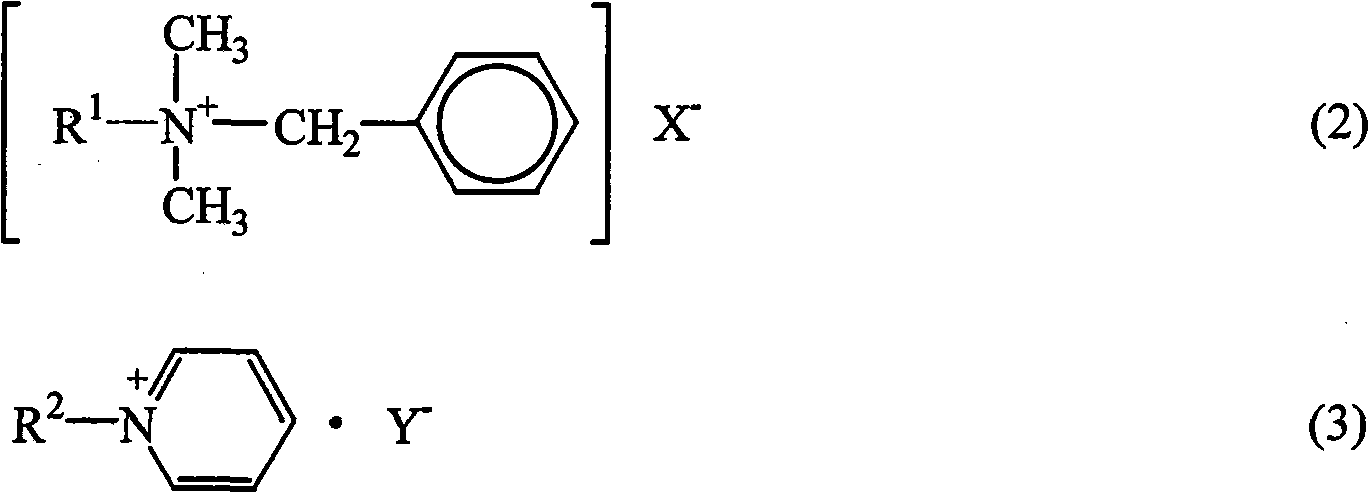

[0169] benzalkonium chloride * 1 0.05

[0170] Polyoxyethylene (60) hardened castor bean oil (HLB 14) 0.5

[0171] Sodium dl-pyrrolidone carboxylate 0.5

[0172] Dipotassium glycyrrhizinate 0.25

[0173] Ethanol 20

[0174] Citric acid 0.25

[0175] Sodium citrate 0.7

[0176] Purified water residual

[0177]

[0178] Total 100.0

[0179] * 1: Alkyl chain length (R 1 ) is C12 / C14=63 / 37 (mass ratio)

[0180] (Evaluation results)

[0181] Shape retention of foam:◎

[0182] No foam remains after rubbing hands:◎

[0183] Easy to dry: ○...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com