Heat accumulating type flue gas waste heat recovery device

A flue gas waste heat recovery device technology, which is applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems that cannot really meet the design requirements of flue gas waste heat recovery devices and waste heat recovery devices. Peak and trough heat problems, to achieve the effect of reducing energy consumption, simple structure, no vulnerable parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

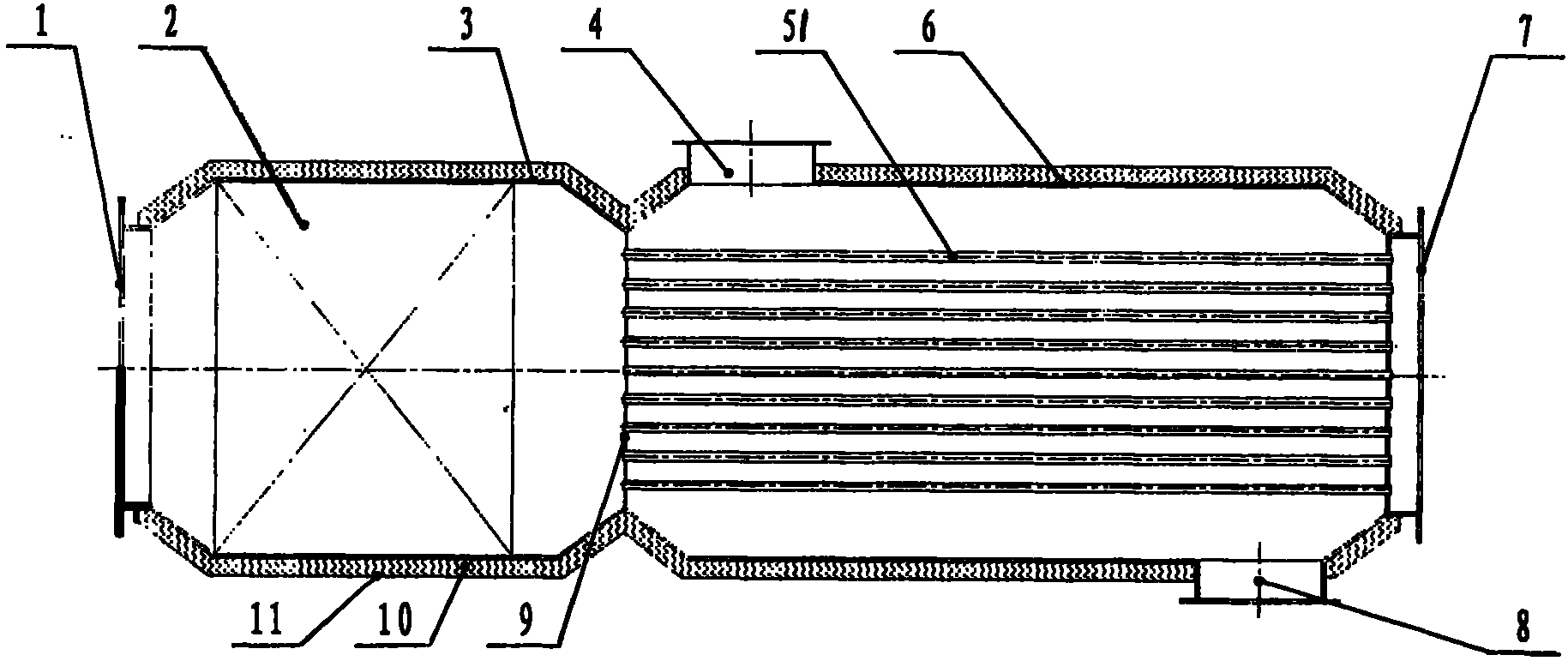

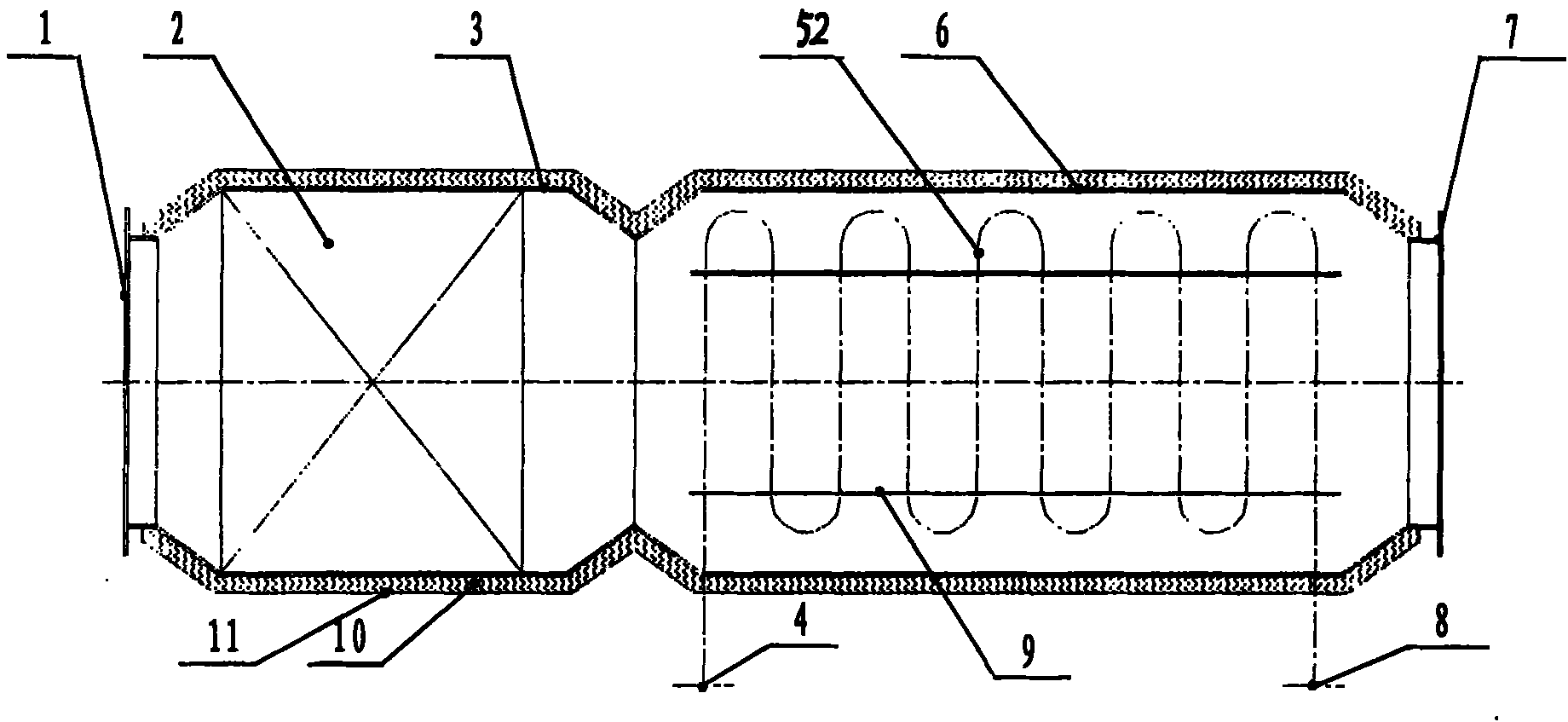

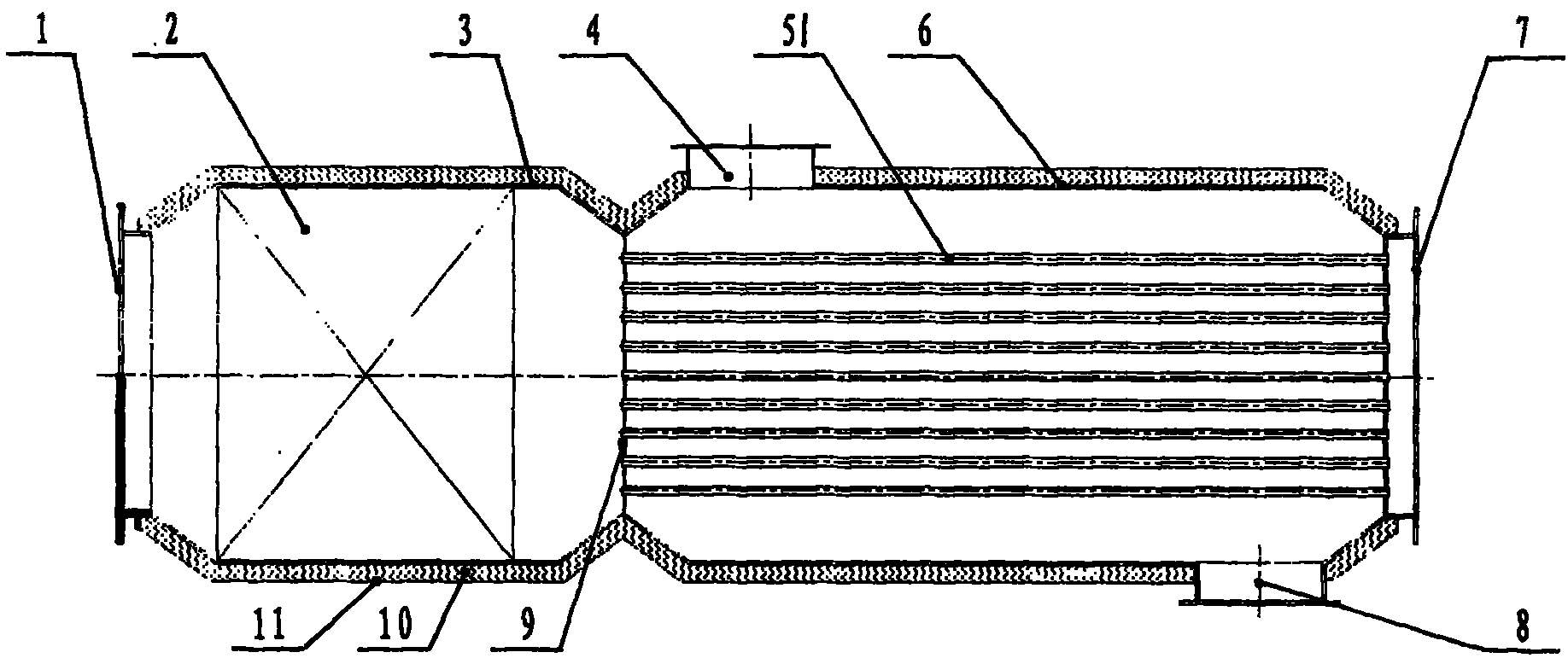

[0024] Such as figure 1 or figure 2 As shown, the regenerative flue gas waste heat recovery device consists of two parts: a heat accumulator and a heat exchanger. From the point of view of the overall structure, the heat accumulator includes a heat accumulator cylinder 3 and a heat storage body 2 arranged in the middle of the heat accumulator cylinder 3 (according to needs, multiple heat storage bodies can also be arranged, and the setting position can also be It is on the inner wall, other places in the cylinder). The front end of the heat accumulator cylinder 3 is provided with a smoke inlet 1, and the rear outlet is directly connected with the heat exchanger (it can also be connected with the heat exchanger through a flue).

[0025] The heat exchanger includes a heat exchanger cylinder body 6 and heat exchange tubes installed in the cylinder body.

[0026] There are two structural forms of heat exchange tubes, one such as figure 1 As shown, it is a parallel tubular hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com