Horizontal boiler radiation segment structure

A radiant section and horizontal technology, which is applied in the field of oil field steam injection boilers and boiler horizontal radiant section structures, can solve problems such as damage, reduce air leakage, increase tonnage, and be less likely to be burned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

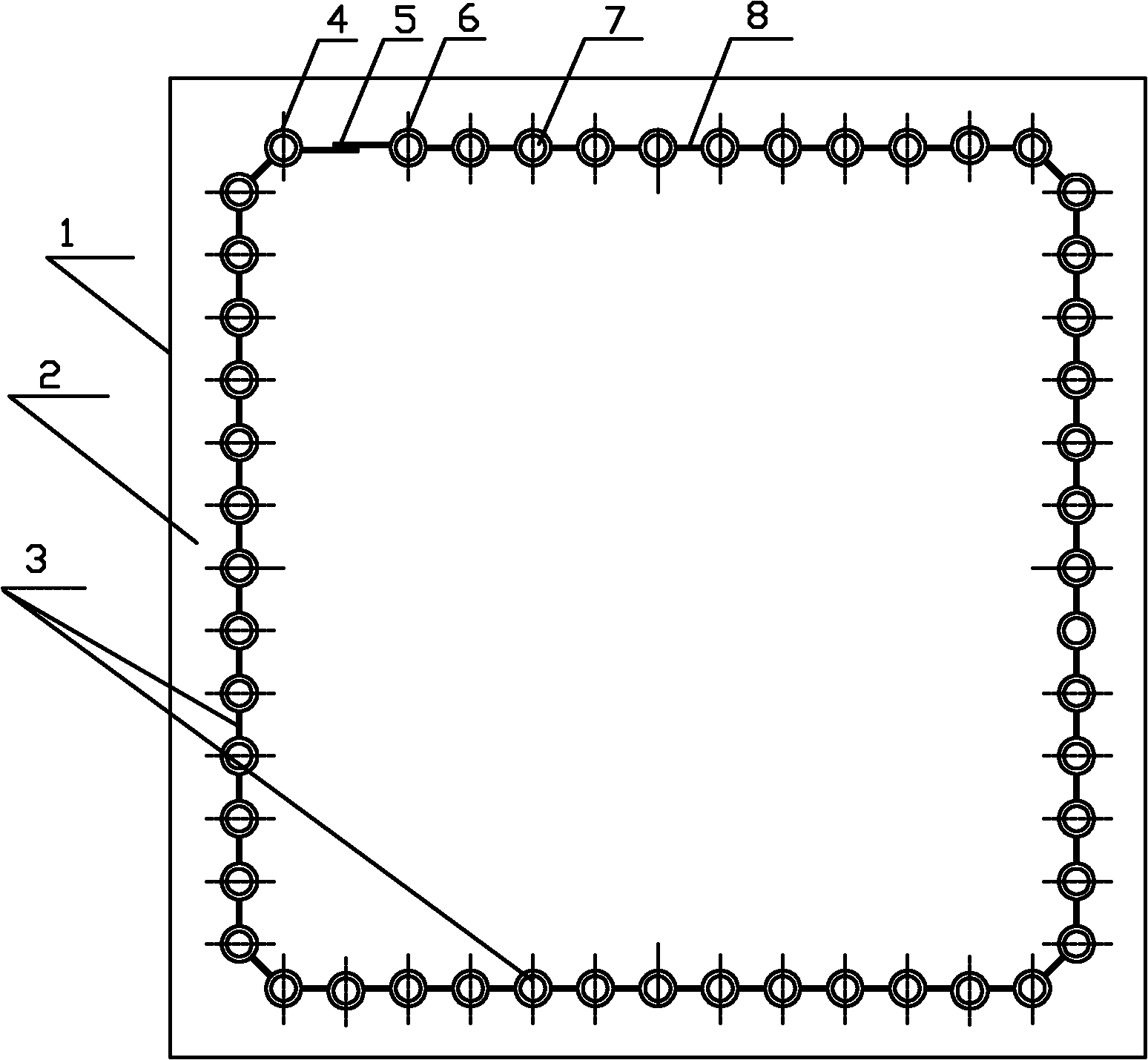

[0024] refer to figure 1 , is a boiler horizontal radiant section structure of the present invention, mainly including an outer sheath 1 and a membrane wall 3, and an insulating layer 2 is provided between the outer sheath 1 and the membrane wall 3. The cross sections of the outer sheath 1 and the membrane wall 3 are both square.

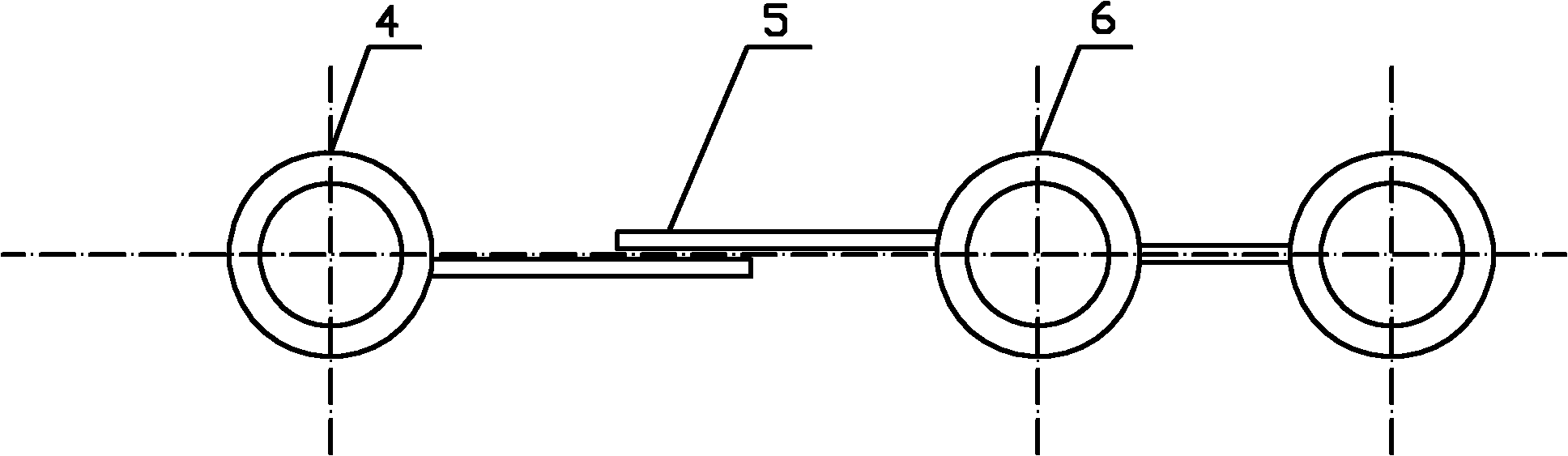

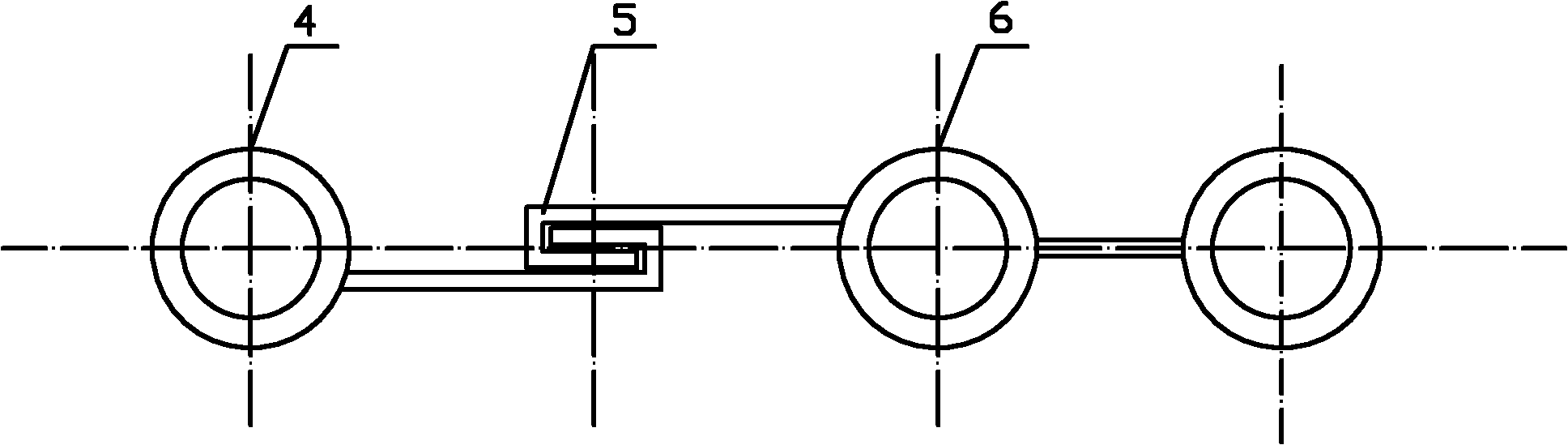

[0025] The membrane wall 3 is composed of a plurality of furnace tubes 7 connected in a serpentine shape and a closed plate 8 connected between the furnace tubes 7. The outlet furnace tube 6 and the inlet furnace tube 4 are located on the upper left of the membrane wall 3, and can also be located on the upper right. Square; 51 furnace tubes 7 are an odd number, therefore, the inlet and outlet of the heating surface of the membrane wall 3 are respectively at the two ends of the furnace body, so that the outlet working medium is directly drawn out, which greatly simplifies the pipeline layout. At the same time, in order to reduce the difference in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com