High-speed rounded bilge type boat utilizing air cavity to reduce resistance

A round bilge and air cavity technology, which is applied to ships, equipment to reduce ship movement, and hulls, can solve problems such as air leakage, drag reduction, and high loss of propulsion systems, so as to reduce frictional resistance, save fuel, and improve propulsion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

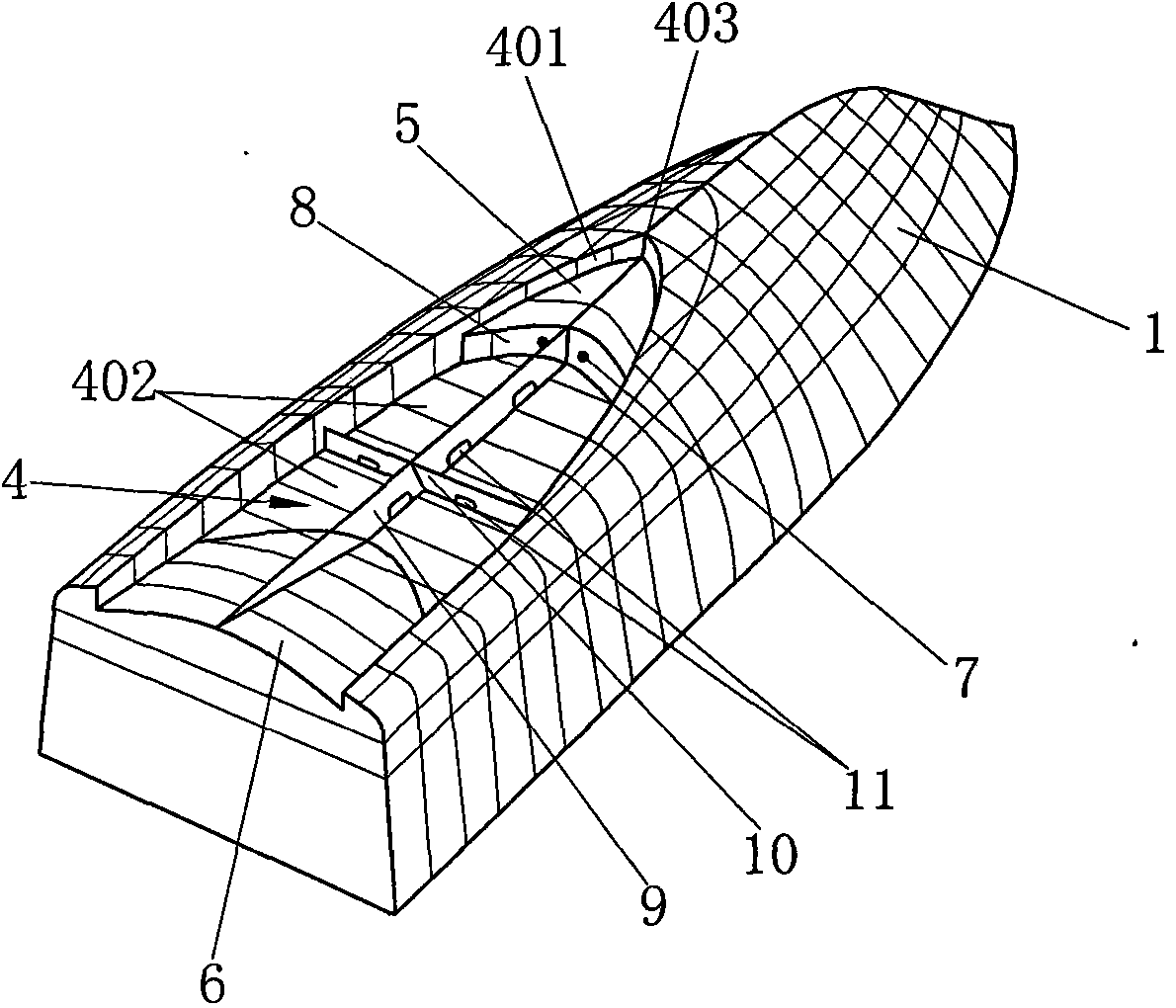

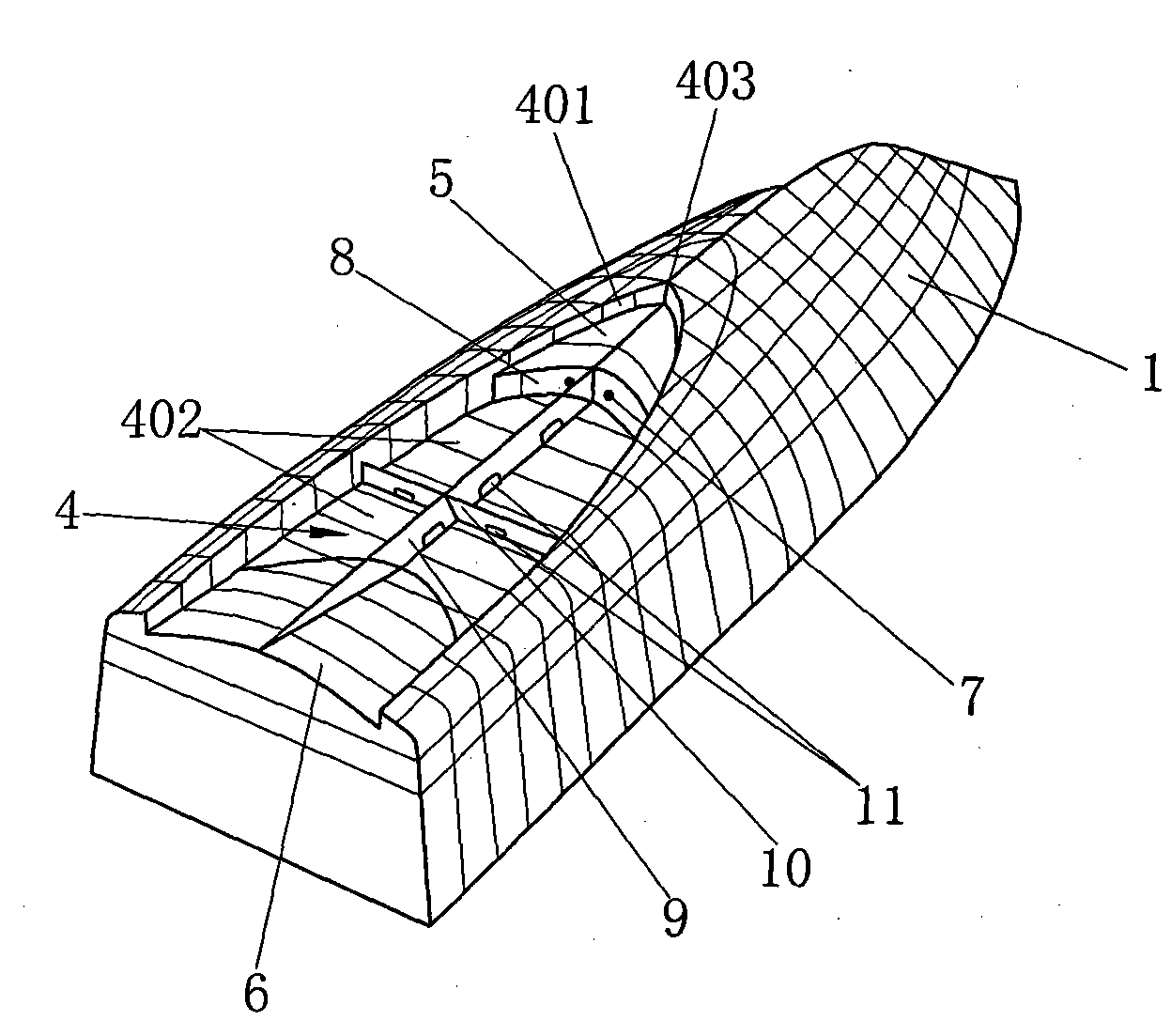

[0017] Such as figure 1 , 2 As shown, the present invention includes a hull 1, a propulsion system 2 and an air supply system 3 arranged in the hull 1. The bottom surface of the hull 1 is provided with an indented air chamber 4, and two side fins 401 forming the air chamber 4 It is arc-shaped, and the width of the air cavity 4 gradually increases from the bow of the hull to the stern of the hull. Such an air cavity structure conforms to the navigation and structural characteristics of high-speed round bilge boats, and reduces the gas in the air cavity 4 during high-speed navigation. The leakage in the middle ensures the effect of drag reduction. The front part of the air chamber 4 is provided with a head platform 5, and the rear part of the air chamber 4 is provided with a wedge-shaped protrusion 6, and the air inlet 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com