Telescoping tube system for vacuum cleaner

A pipe system and vacuum cleaner technology, applied in the field of pipe systems, can solve the problems of reduced suction force, uneven flow, etc., and achieve the effects of improved suction efficiency, uniform flow profile, and reliable insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

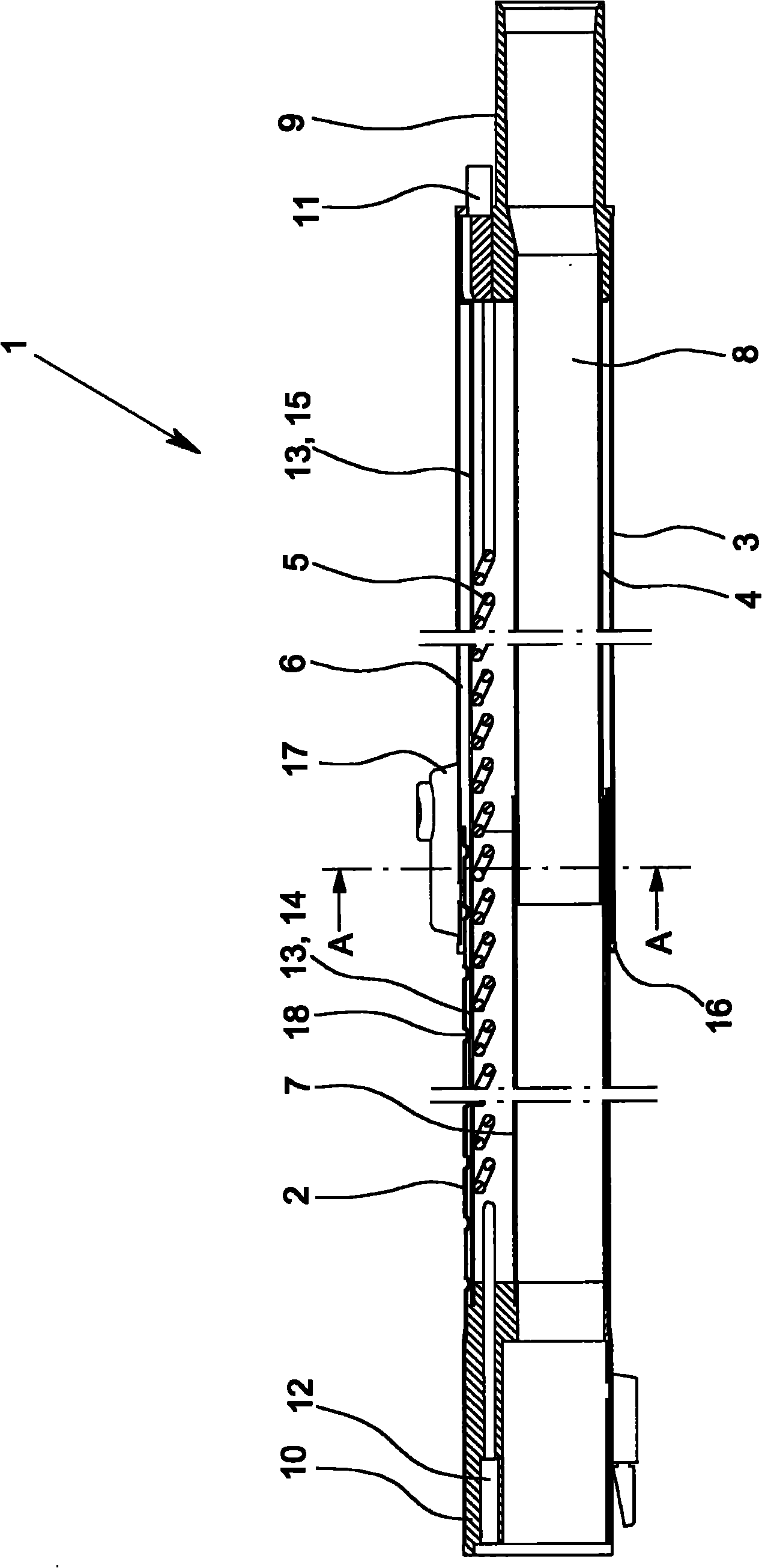

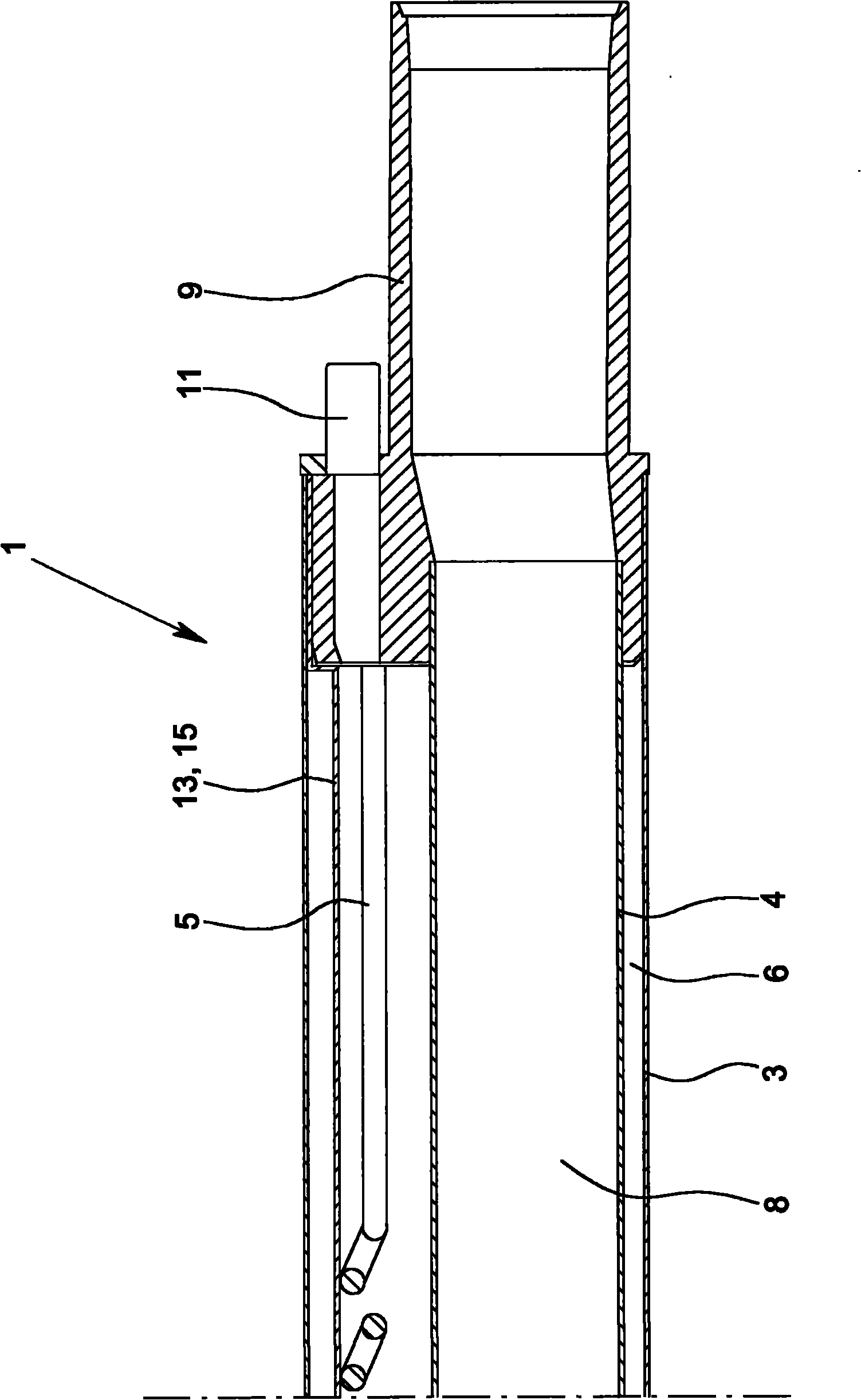

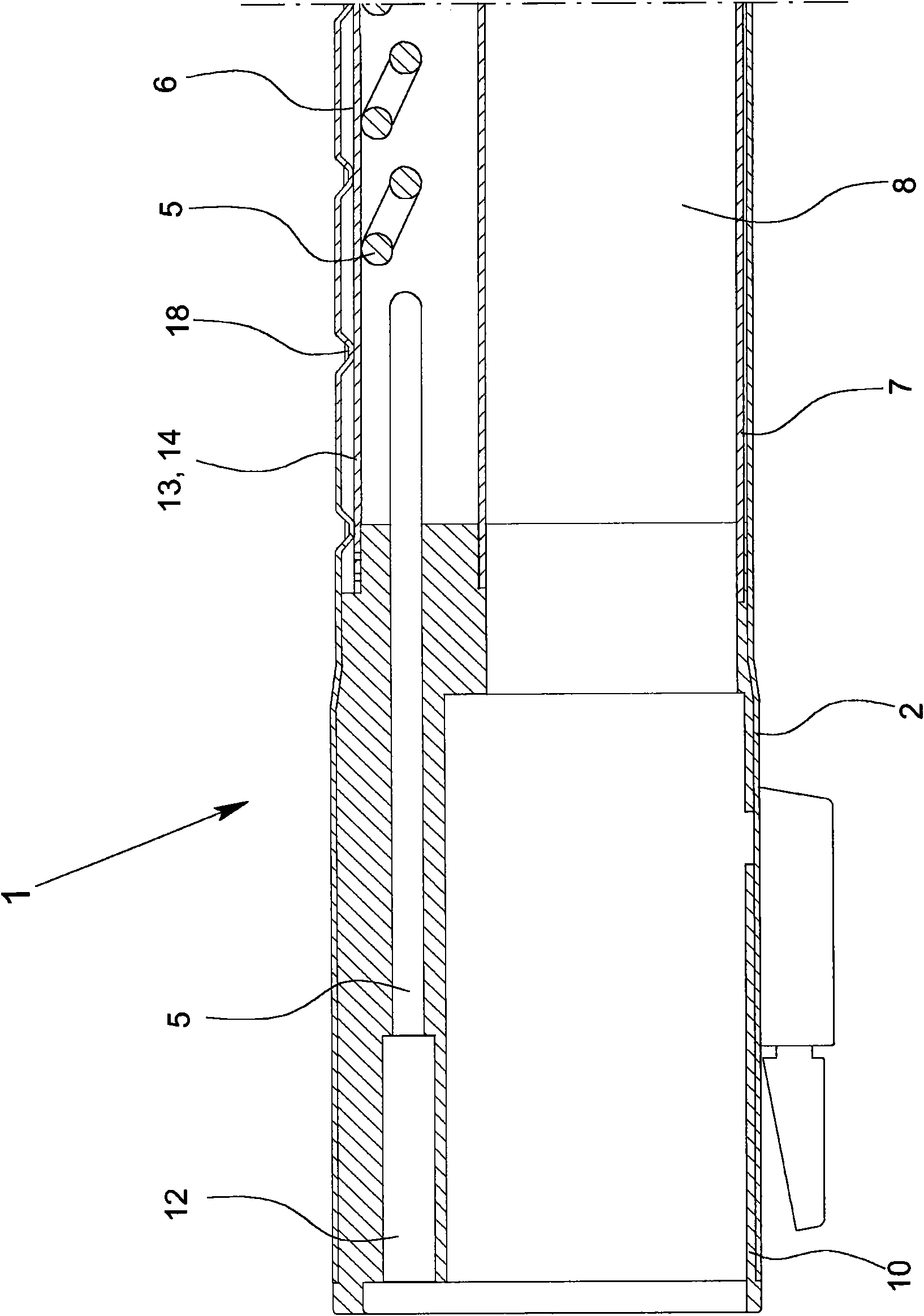

[0028] figure 1 A telescoping pipe system 1 for a vacuum cleaner is shown, which has an inner housing pipe 2 , an outer housing pipe 3 , an inner suction pipe 4 and a cable 5 . The inner shell tube 2 has a smaller cross-section than the outer shell tube 3 , so the inner shell tube 2 and the outer shell tube 3 form a telescopic shell channel 6 . The housing channel 6 surrounds the suction inner tube 4 and the cable 5 , wherein the cable 5 is guided inside the housing channel 6 and outside the suction inner tube 4 . The suction inner tube 4 together with the suction outer tube 7 forms a substantially closed suction channel 8 . The suction channel 8 extends inside the housing channel 6 and is arranged eccentrically in the housing channel 6 .

[0029] Both the housing channel 6 and the suction channel 8 are scalable in their length, since the outer housing tube 3 is movable relative to the inner housing tube 2 and the outer suction tube 7 is movable relative to the inner suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com