Combined circular groove for butterfly valve seat of molecular sieve

A butterfly valve seat and combination ring technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of easy leakage, high processing cost, short life, etc., to ensure two-way sealing, improve performance level, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

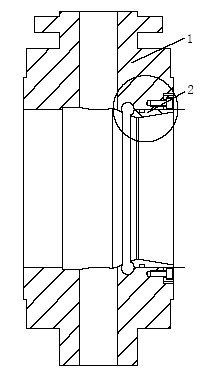

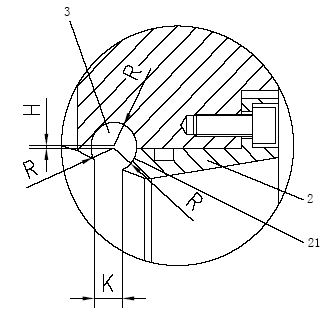

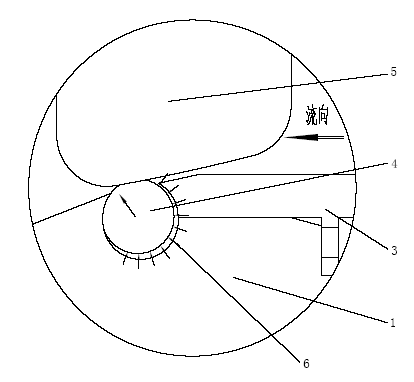

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a combined ring groove for the valve seat of a molecular sieve butterfly valve. The combined ring groove has three sections of circular arc surfaces with equal radii, two of which are on the valve body 1, and one section is on the pressure ring 2. The two arc surfaces on the valve body 1 are connected by two arc surfaces with a radius R and a center distance H concave inward. One side of the valve body 1 is screwed to the pressure ring 2, and the root of the pressure ring 2 is provided with a The concave arc surface 21 forms a combined ring groove 3 with the arc surface on the valve body 1 . The radius of the arc surface 21 at the root of the pressure ring 2 is R, and the center of the arc surface 21 coincides with the center of the arc surface of the inner section of the valve body 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com