Self-destruction screw

A screw and self-explosion technology, which is applied in the direction of screws, threaded fasteners, vehicle safety arrangements, etc., can solve the problem of theft of safety hammers, achieve the effects of low manufacturing cost, simple structure, and time-saving escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

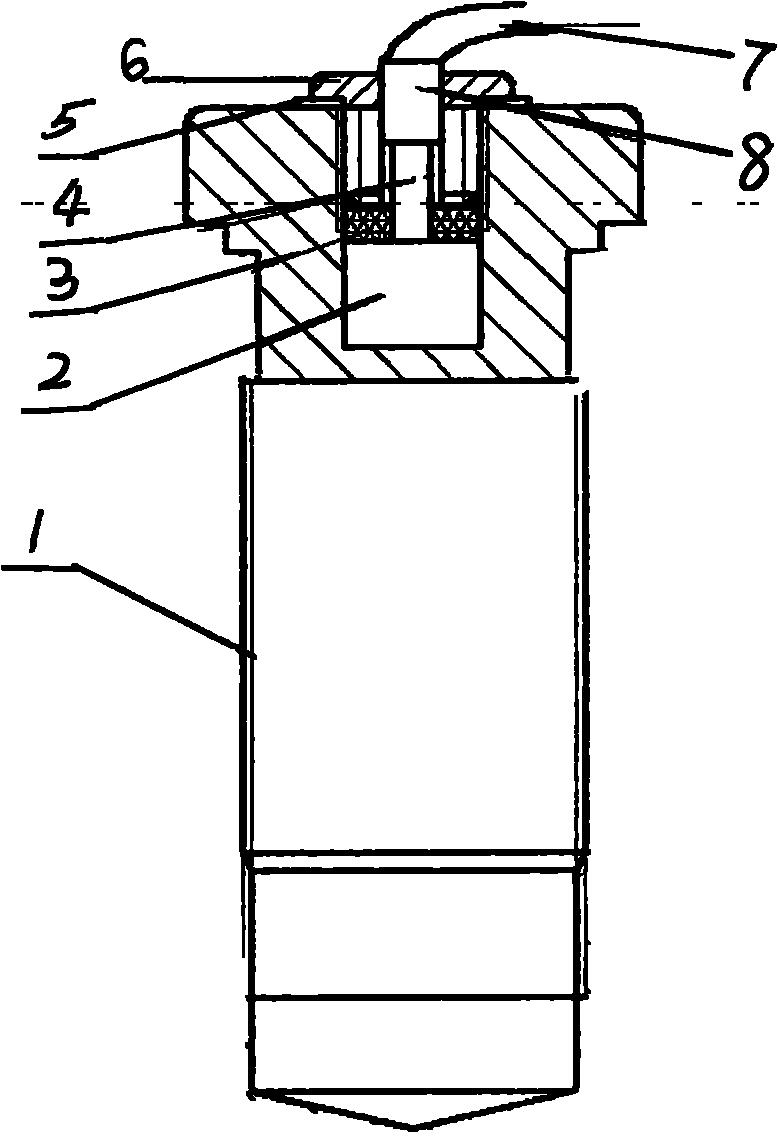

[0008] Example: figure 1 As shown, this embodiment includes a stud 1 with external threads, which is characterized in that a blind hole is provided on the screw head, and a detonator 2, a retainer 3, and a fixed cover 6 are arranged in the blind hole in turn, and the electrode head 4 of the detonator 2 passes through Electric wire 7 is connected with detonation switch.

[0009] The current connected to the external wire 7 enters the detonator 2 through the detonator electrode head 4, thereby detonating it. After the explosion, the screw body part where the detonator 2 is located is broken, so that the outer window frame is separated from the compartment body. The retaining ring 3 has the functions of shockproof, moisture-proof, heat insulation and sealing, and prevents the detonator from being detonated by bad external factors. The detonation voltage of the detonator is DC 1.2V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com