Groove bottom-reinforced fully lined debris flow drainage groove and construction method thereof

A drainage channel and debris flow technology, applied in dikes, coastline protection, dams, etc., can solve the problems of full channel damage, difficult to popularize and apply in large areas, drainage channel damage, etc., to save engineering maintenance costs, ensure operation safety, The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

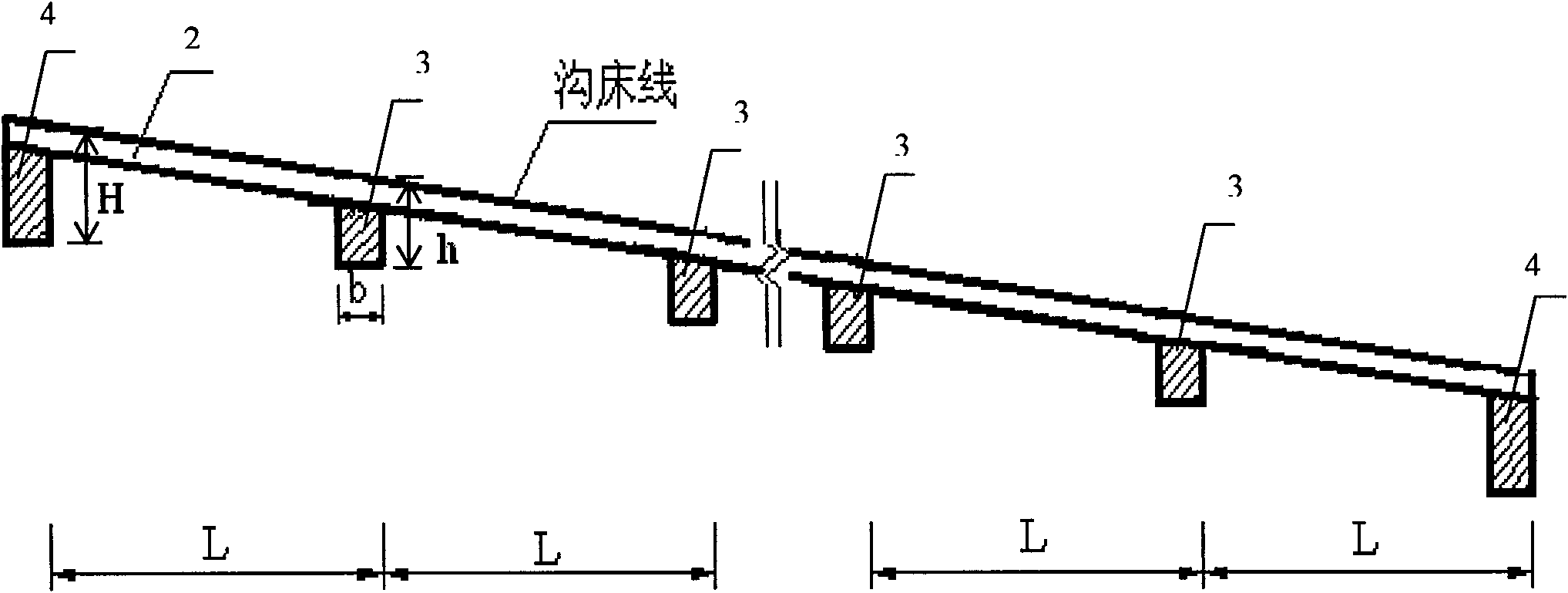

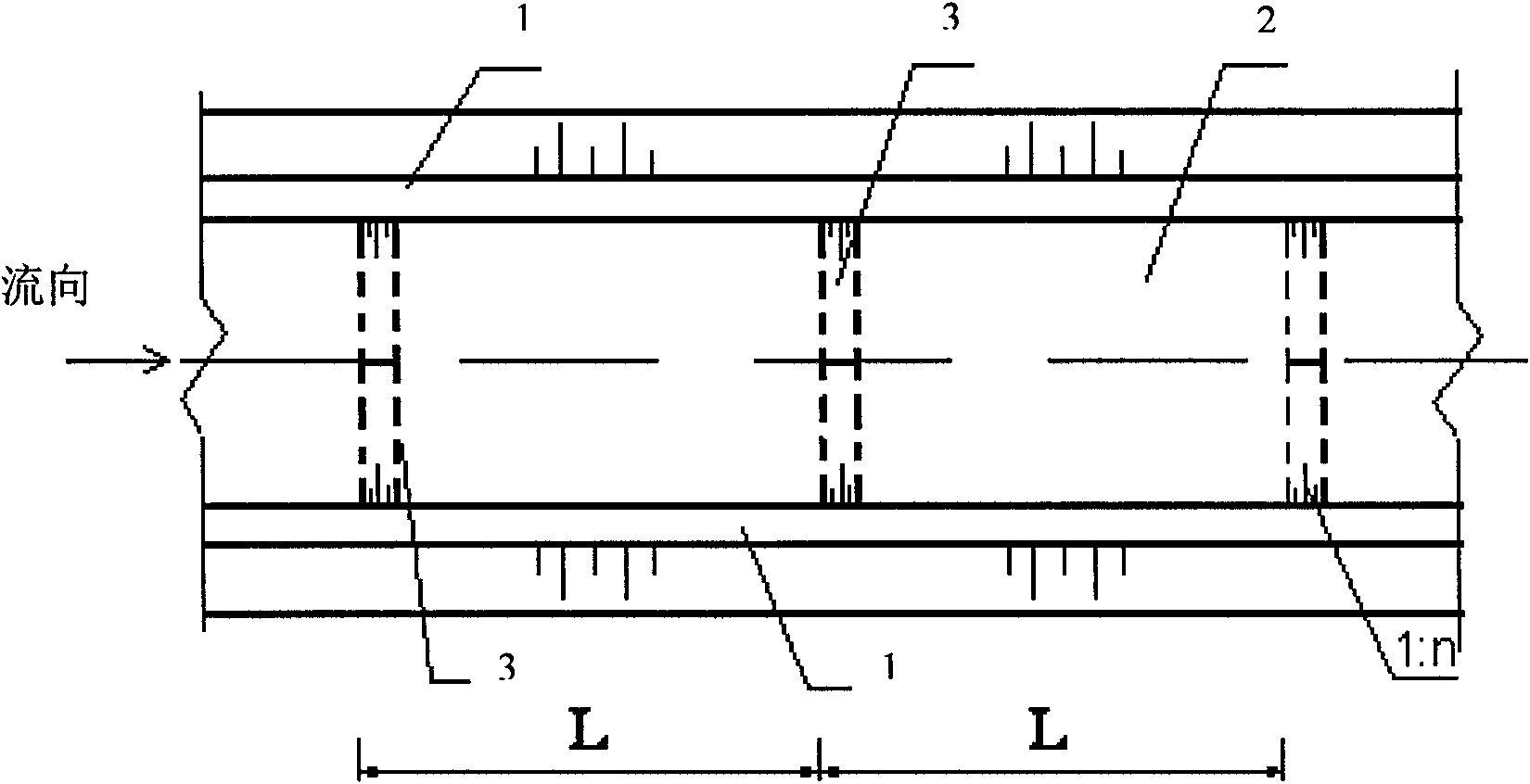

[0038] Such as figure 2 , image 3 , Figure 4 , Figure 5 shown. For a watershed area of 1.5km 2 , The accumulation fan slope is 18%. On the debris flow accumulation fan, a V-shaped full-lined debris flow drainage trough reinforced at the bottom of the trough is built. The length of the trough is 200m, including the fully lined trough bottom plate 2 and the side walls 1 of the trough on both sides. In the foundation and below the guide groove, there are 11 submerged sills that run transversely along the guide groove, are connected with the bottom plate 2 of the guide groove, are distributed at certain intervals, and have a certain effective buried depth. The distance L between the submerged sills is 20.0m; the width b of the submerged sills is 1.0m in the longitudinal direction along the side wall 1 of the guide trough; the engineering structure of the submerged sills adopts concrete structure; The design shape is consistent, it is V-shaped, the upper surface of the ...

Embodiment 2

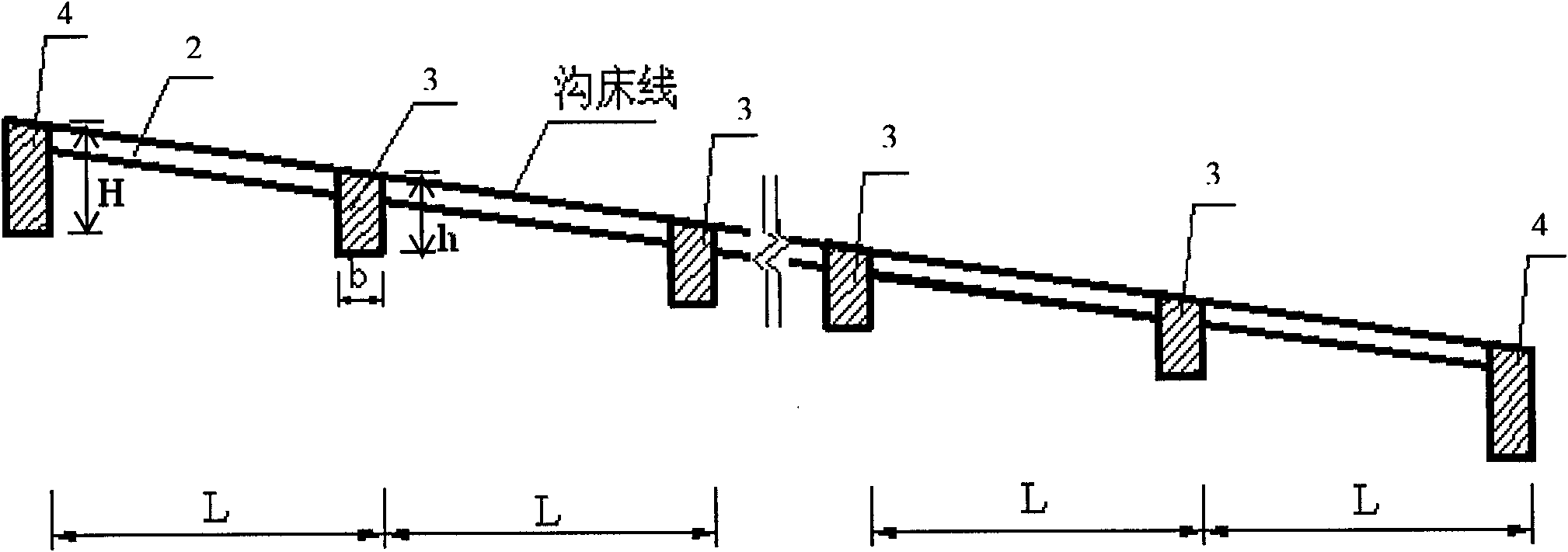

[0044] Such as figure 1 , Figure 6 , Figure 7 , Figure 8 shown. For a watershed area of 20.0km 2 , The slope of the accumulation fan is 5%. The same thing as Embodiment 1 will not be repeated, and the difference is that the length of the guide trough is 800m, and there are 9 sills, and the 2 sills at the entrance and exit of the guide trough are deepened sills 4. The remaining 7 diving sills at other positions of the guide groove are common diving sills 3 . The shape of the bottom of the guide trough is trapezoidal; the distance L between the submerged sills is 100.0m; along the longitudinal direction of the side wall 1 of the guide trough, the width b of the submerged sill is 2.5m; the engineering structure of the submerged sill adopts reinforced concrete structure; The shape of the upper surface of the submerged sill is consistent with the design shape of the bottom of the groove, which is trapezoidal. The transverse vertical slope of the bottom plate 2 of the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com