Automatic circular seam welding pipe tongs

A technology of automatic welding and pipe tongs, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low welding efficiency, difficult welding process, and difficult quality assurance, so as to improve work efficiency and shorten installation time. The effect of clamping time and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

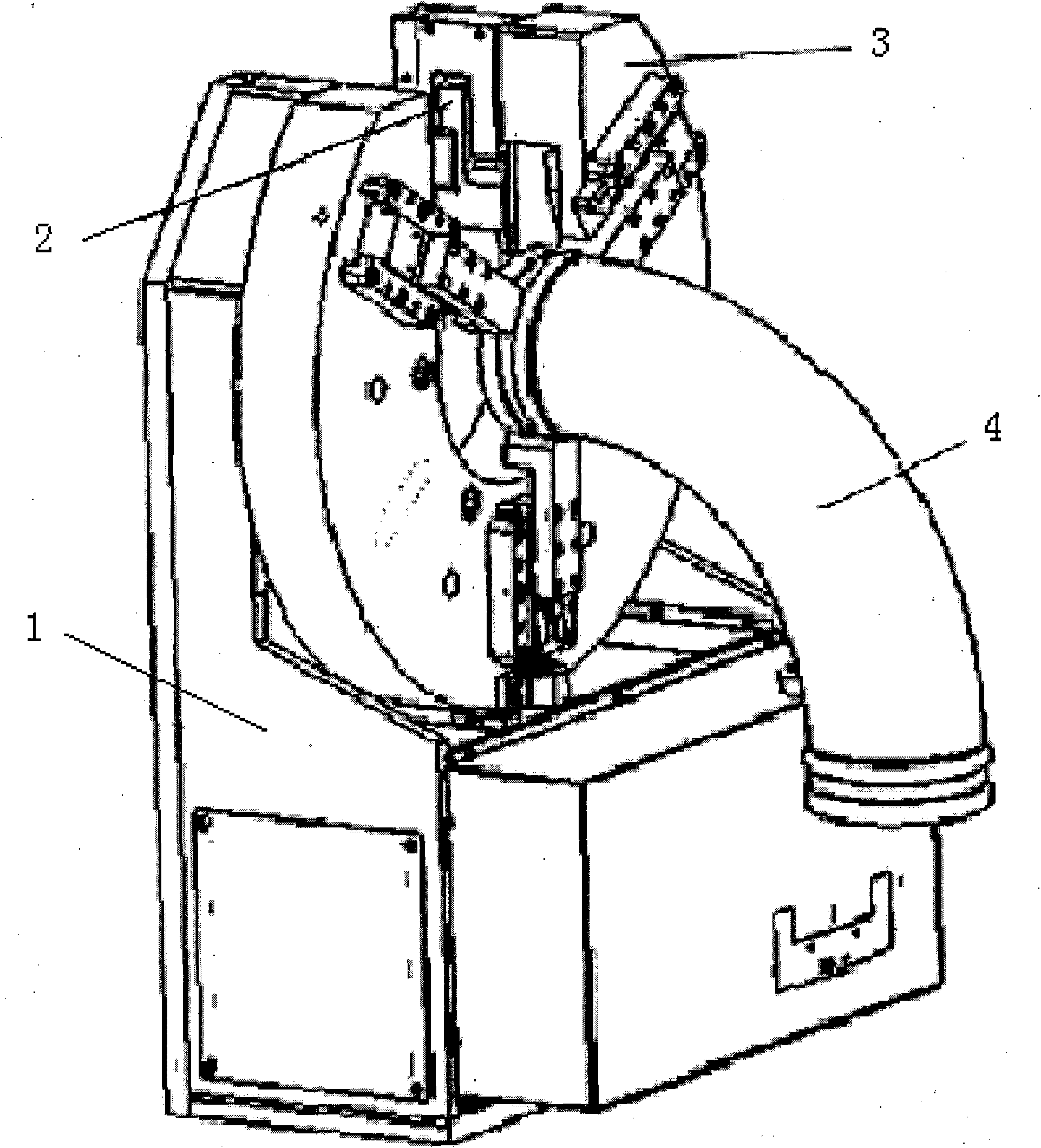

[0025] Such as figure 1 As shown, the circular seam automatic welding pipe tongs of the present invention is a welding tool used for automatic welding of the internal and external angle circular seams of pipe fittings or flanges. One side of the driving and rotating mechanism 2 is connected and fixed with the U-shaped base box 1. The other end of the driving and rotating mechanism 2 is connected to a self-centering positioning and clamping mechanism 3 , and the workpiece 4 is clamped in the self-centering positioning and clamping mechanism 3 .

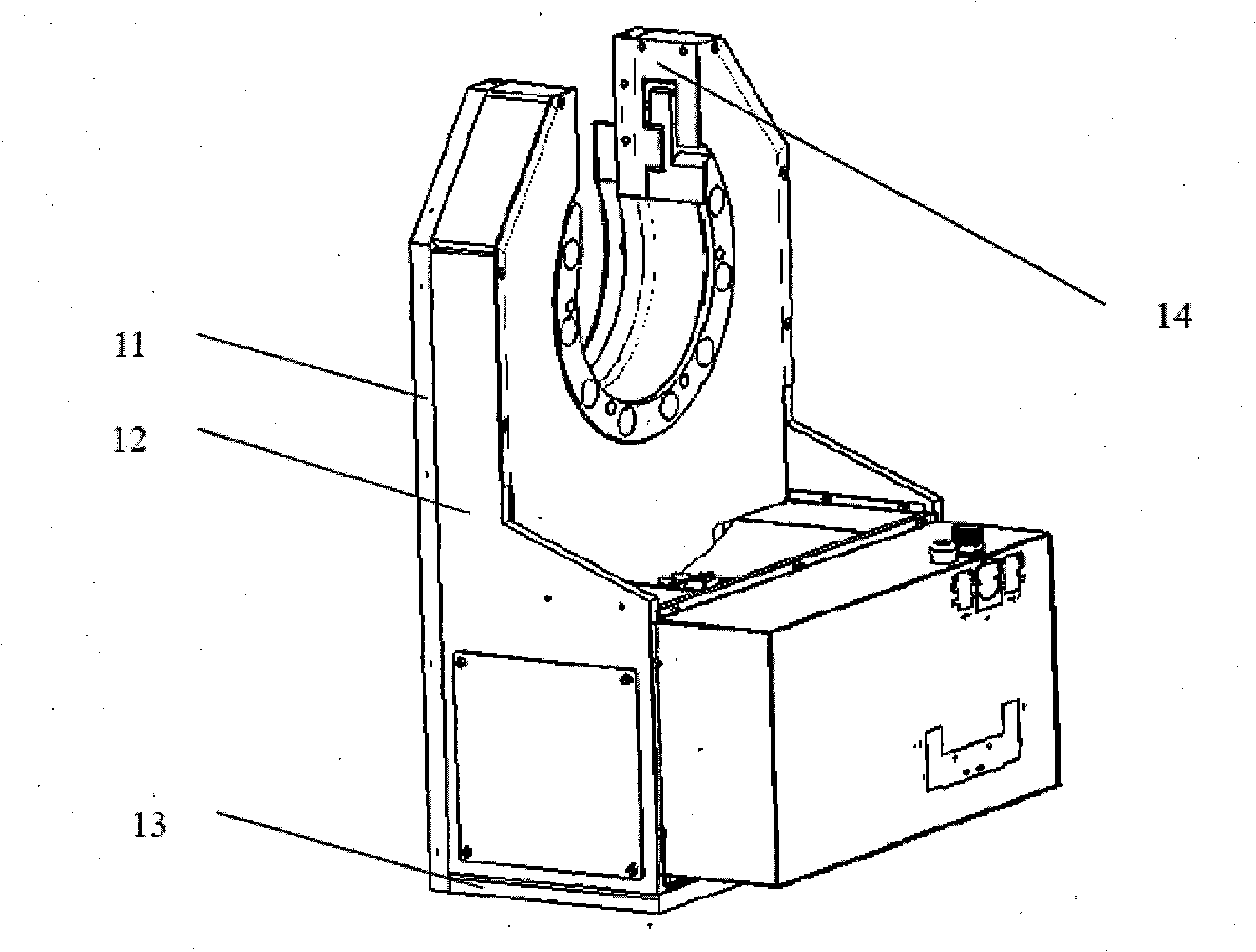

[0026] Such as figure 2 As shown, the U-shaped base box 1 is welded by a main board 11 , a side board 12 , a bottom board 13 and a sealing board 14 , and a U-shaped groove is opened at one end of the main board. In order to enhance the structural strength of the box, stiffener plates can also be welded at appropriate positions.

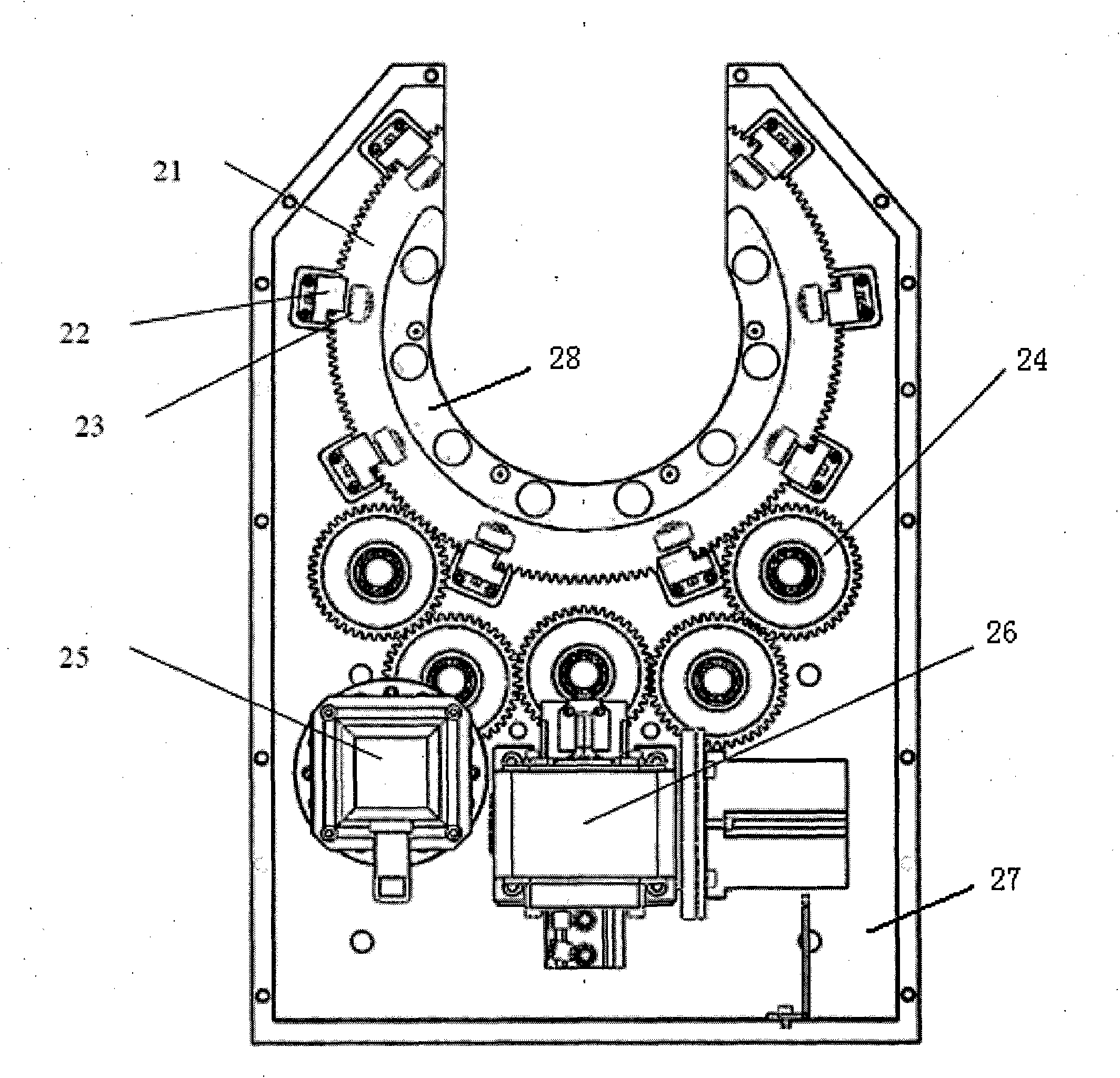

[0027] Such as image 3 , Figure 4 As shown, the drive and rotation mechanism 2 includes a rotary rin...

Embodiment 2

[0032] On the basis of Example 1, the preferred embodiment of the present invention is, as Figure 3-Figure 5 As shown, there are five transition gears 23, which are in external mesh with each other in turn, and the two transition gears 23 at both ends are in external mesh with the rotating ring gear 21.

[0033] The three-jaw guide mechanism 32 comprises four guide plates 35 and five guide blocks 36, and the chute 37 corresponding to the guide blocks 36 is also five, and the two ends of the guide plates are all provided with U-shaped grooves, which are connected with the guide blocks 36 at intervals. Top board 31 is three pieces.

[0034] After the jacking drive 26 is started, it moves upwards to contact the adjustment locking screw 34, and pushes the adjustment locking screw 34 to contact the guide block in the middle of the five guide blocks 36 in the three-claw guide mechanism 32. The middle guide block 36 moves along the chute 37. Moving up (that is, moving toward the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com